Circular tube drilling and pin pressing machine tool

A technology for machine tools and round pipes is applied in the field of automatic and rapid round pipe drilling and pressing machine tools, which can solve problems such as unfavorable automation, and achieve the effects of good work effect, high processing efficiency and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

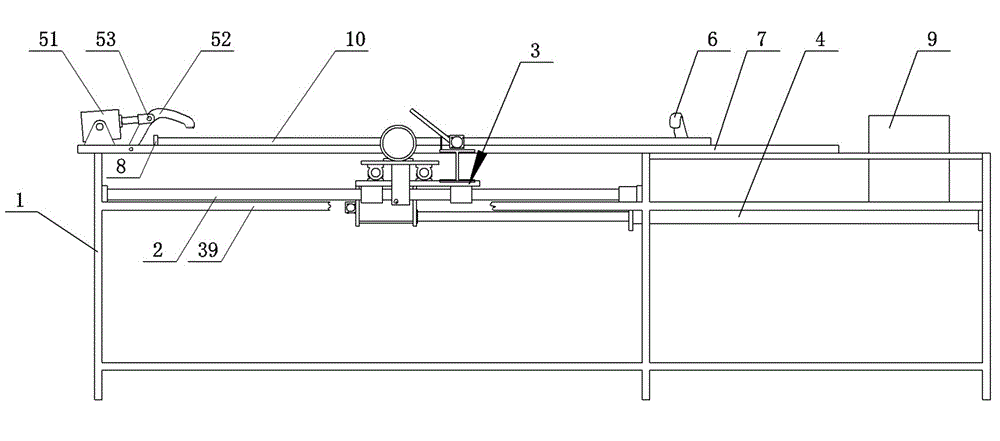

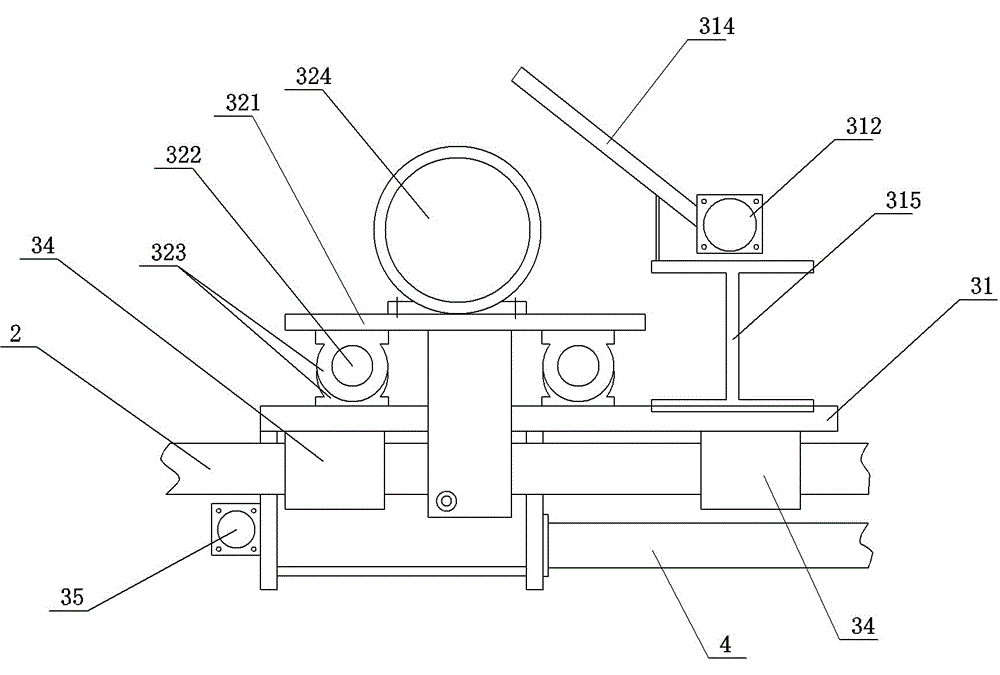

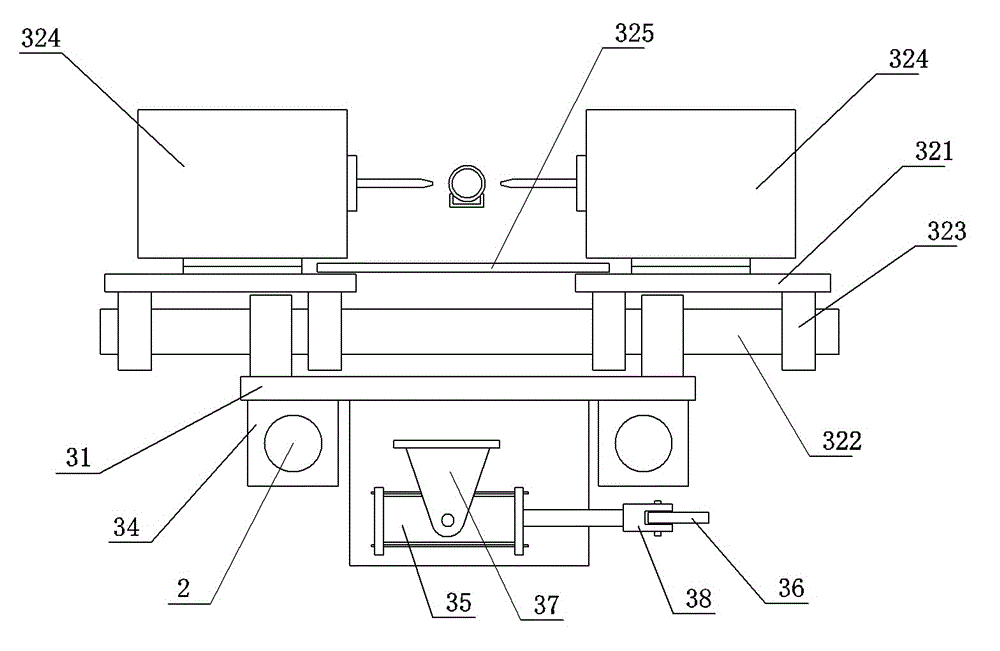

[0025] Embodiment: a kind of circular pipe drilling and pressing pin machine tool, see figure 1 , a walking platform 3 is set on the frame 1, a hydraulic or pneumatic system, an electrical cabinet 9, etc. are also set. The middle part of the frame 1 is equipped with a steel pipe positioning groove 7 along the longitudinal direction, and the rear end of the positioning groove is fixed with an end positioning block 8. The front and rear ends of the frame 1 are respectively provided with clamps for fixing steel pipes, and the two sides of the frame 1 are installed in parallel. There is a longitudinal guide rail 2; the walking platform 3 is installed on the longitudinal guide rail 2; the bottom of the walking platform 3 is connected with one end of the frame 1 with a longitudinal push oil cylinder 4; the walking platform 3 is provided with a walking positioning switch and a braking mechanism. The walking platform slides along the longitudinal direction of the machine tool, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com