pipe saw

A pipe and saw blade technology, applied in the field of tools for cutting pipes, can solve the problems of uneven cutting section, burrs, labor and other problems, and achieve the effect of smooth cutting section and fast sawing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

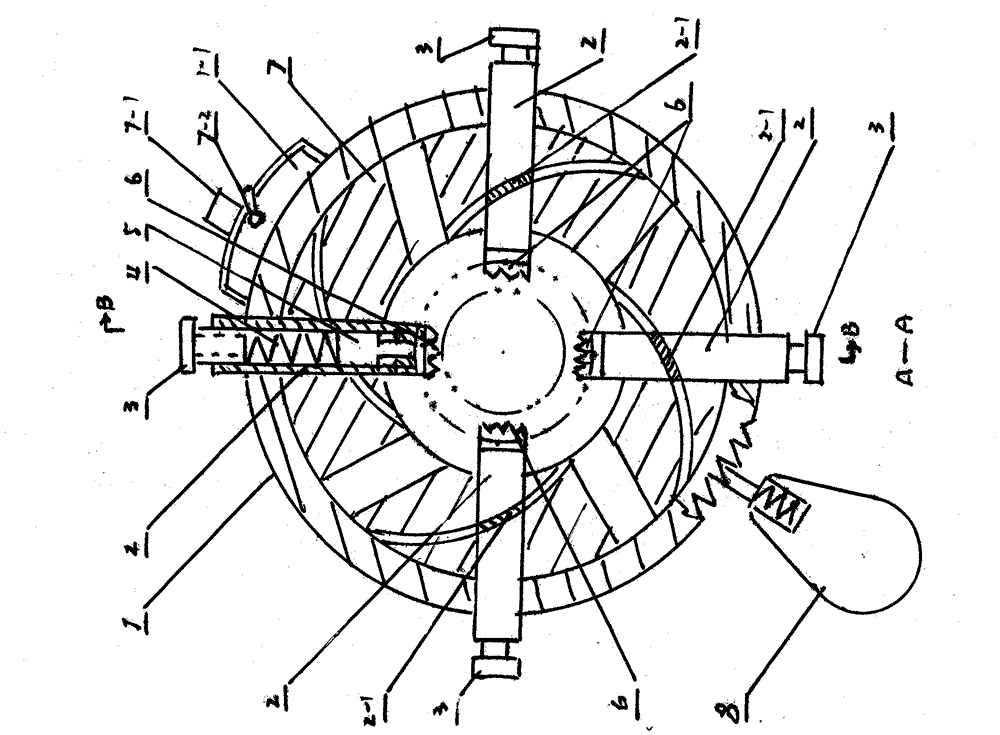

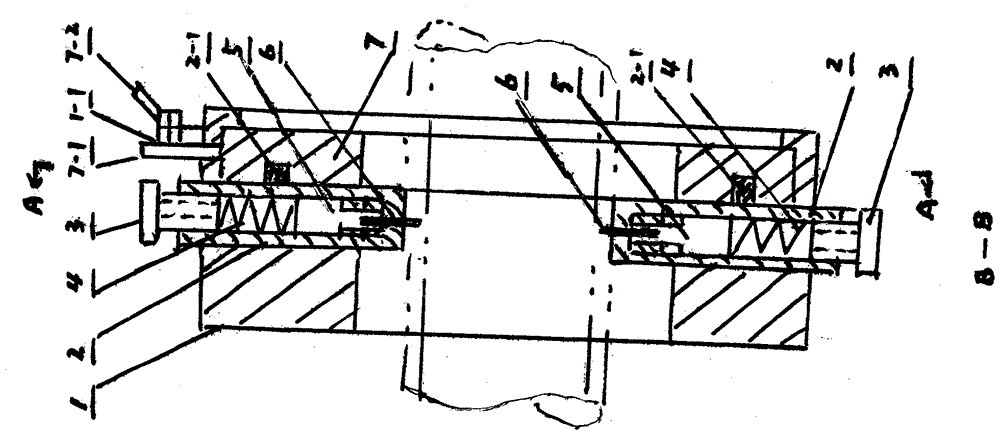

[0009] exist figure 1 , 2 In the shown embodiment, four rectangular holes and a circle of ratchets are uniformly arranged around the circular shell 1, and a long arc hole 1-1 is provided on the outer circle of the circular shell 1. The slider 2 is rectangular with a long hole in the middle of the upper end and a slot at the lower end. One side of the slider 2 is provided with a square convex spiral tooth 2-1, and a protruding handle 7-1 is provided on the plane square concave spiral tooth plate 7. , one side of the concave spiral tooth plate 7 is provided with 4 square concave spiral teeth, the size and shape of the concave spiral teeth and the convex spiral teeth 2-1 are the same, and the screw 7-2 passes through the circular arc hole 1-1 on the circular shell 1 and rotates Put the handle 7-1 into the screw hole, and fix the handle 7-1. The 4 sliders 2 are inserted into the four holes of the circular shell 1, and the concave helical toothed disc 7 is rotated, and the convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com