Method for achieving rapid low-temperature extrusion formation of 6063 aluminum alloy

An extrusion molding and aluminum alloy technology, which is applied in heat treatment equipment, quenching equipment, manufacturing tools, etc., can solve problems such as unsatisfactory results, and achieve the effects of reducing extrusion force, enhancing rheology, and increasing inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

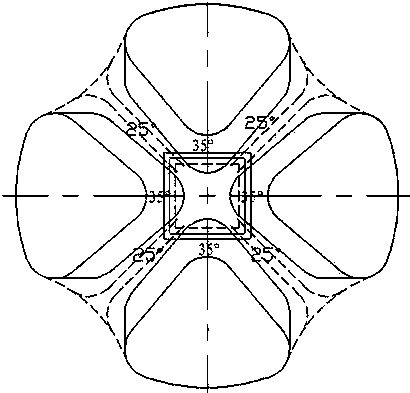

[0023] Melting and preparing (mass percentage) 6063 alloy with Si content of 0.445% and Mg content of 0.536% in the smelting and holding furnace, refining, cooling to casting temperature and holding for 20 minutes to make the temperature and composition of the alloy melt uniform, and then casting into alloy rods. Before extrusion, the aluminum rod is preheated to 435°C. The mold inlet chamfer used in the extrusion process is 37°, the discharge port is chamfered at 25°, and the outflow angle is inclined at 5°. The cooling rate of the extruded profile is 250°C / min, the mechanical properties of the profile: the tensile strength is 210MPa-218MPa, and the elongation is 9.31%-9.63%.

Embodiment 2

[0025] Melting and preparing (mass percentage) 6063 alloy with Si content of 0.453% and Mg content of 0.522% in the smelting and holding furnace, refining, cooling to casting temperature and holding for 20 minutes to make the alloy melt temperature and composition uniform, and then casting into alloy rods. Before extrusion, the aluminum rod is preheated to 425°C. During the extrusion process, the chamfering angle of the mold inlet is 35°, the chamfering angle of the outlet is 25°, and the outflow angle is inclined at 4°. The cooling rate of the extruded profile is 280°C / min, the mechanical properties of the profile: the tensile strength is 222MPa-232MPa, and the elongation is 9.15%-9.49%.

Embodiment 3

[0027] Melting and preparing (mass percentage) 6063 alloy with Si content of 0.459% and Mg content of 0.514% in the melting and holding furnace, refining, cooling to casting temperature and holding for 20 minutes to make the alloy melt temperature and composition uniform, and then casting into alloy rods. Before extrusion, the aluminum rod is preheated to 415°C. The mold inlet chamfer used in the extrusion process is 33°, the outlet chamfer is 25°, and the outflow angle is inclined 3°. The cooling rate of the extruded profile is 300°C / min, the mechanical properties of the profile: the tensile strength is 212MPa-224MPa, and the elongation is 8.91%-9.23%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com