Preparation method of silver oxide as ultraviolet/visible/infrared photocatalyst

A technology of photocatalytic oxidation and visible light, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low catalyst recovery rate and low solar energy utilization rate , to achieve the effects of low recycling rate, simple preparation method and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

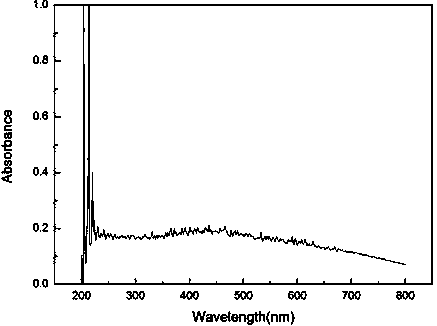

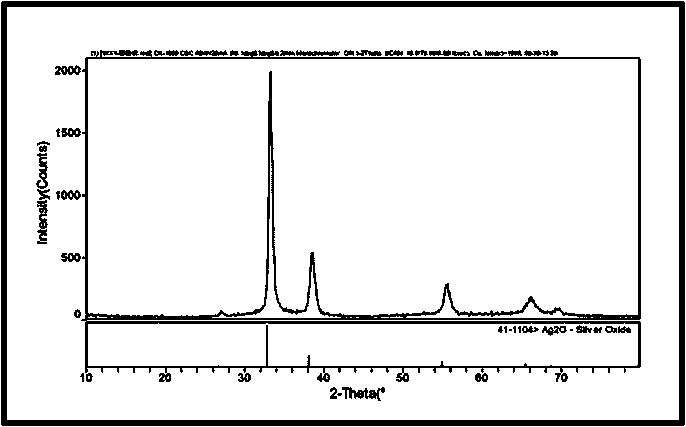

Image

Examples

Embodiment 1

[0029] Weigh a certain amount of silver acetate, silicic acid, and cesium hydroxide solid, and then dissolve them in deionized water to prepare 0.05-2mol / L silver acetate solution, 0.02-1mol / L silicic acid solution and 0.03-3mol / L L cesium hydroxide solution, first silicic acid solution and cesium hydroxide solution are mixed, then under the condition of magnetic stirring, described mixed liquid is added dropwise in the described silver acetate solution, obtains precipitation, after dropwise addition, Continue magnetic stirring for 2.5 h at room temperature under the condition of avoiding light, filter, wash the precipitate with deionized water, and dry at 50° C. to obtain a silver oxide photocatalyst with infrared / visible / ultraviolet photocatalytic effect.

Embodiment 2

[0031] After mixing the silicic acid solution and the cesium hydroxide solution in the above embodiment 1, it can be directly mixed with silver acetate, then placed in a hydrothermal kettle, heated at 60-220°C for 1-72h after tightening, and the water is taken out Heat the kettle, cool to normal temperature to obtain precipitate, then filter, wash, and dry at 50°C to obtain a silver oxide photocatalyst with infrared light / visible light / ultraviolet photocatalytic effect.

Embodiment 3

[0033] Change the silver acetate in the above embodiment 1 and embodiment 2 to silver fluoride or silver nitrate, still can get precipitation, after filtering, washing, drying at 50 ℃, get the photocatalytic effect of infrared light / visible light / ultraviolet light silver oxide photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com