A method for the surface application of chemical compounds to both synthetic and natural fibers and a system for same

一种化合物、纤维的技术,应用在无机化合物添加、纤维处理、生化纤维处理等方向,能够解决活性和保护的能力不可获得等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

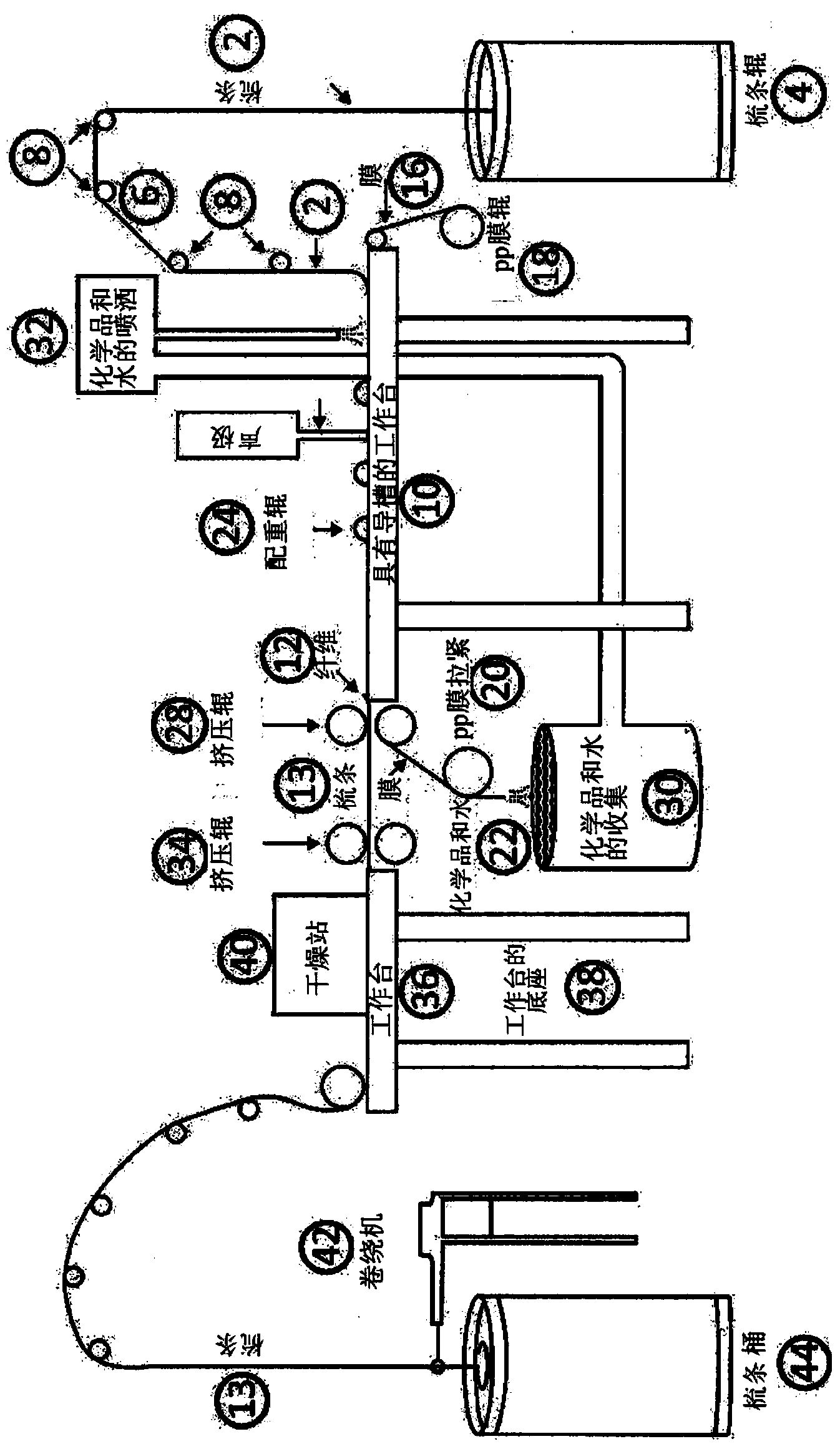

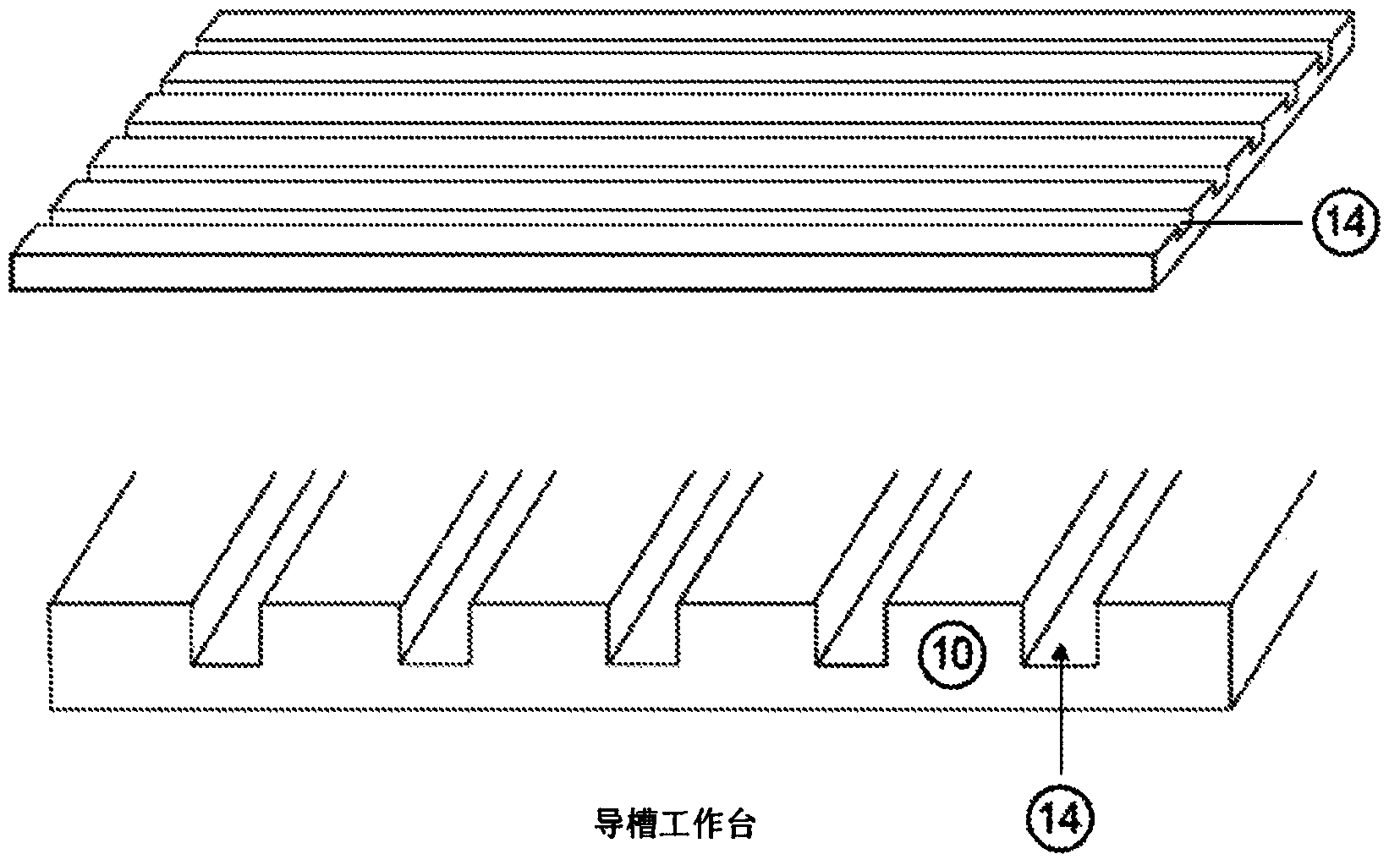

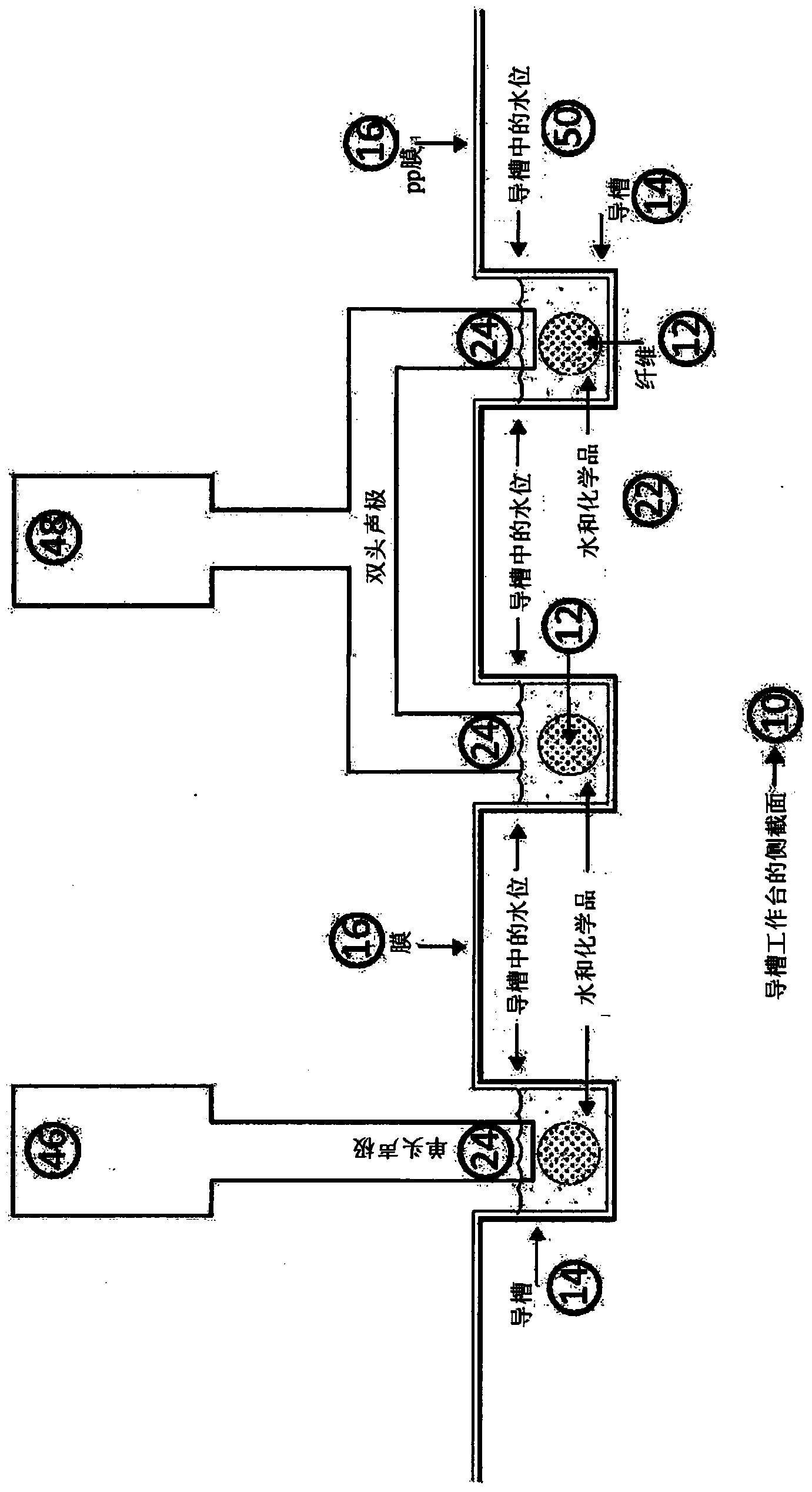

Method used

Image

Examples

Embodiment 1

[0224] Flame Retardant Chemicals Containing Water of Hydration

[0225] The sliver is prepared such that it has a low twist (about 4 twists per meter) and weighs 3 to 8 grams per meter. The sliver can be made from any staple fiber such as, but not limited to, cotton, rayon, polyester and nylon. The sliver is run through the system as described, but before the sliver is placed in the channel of the belt, a small amount of a flame retardant (FR) chemical compound in the form of a fine powder (typically no larger than 5 microns in size) is placed in the water, The water is sprayed on the fibers. It should be noted that FR can also be placed on a dry strip. When the radio waves are turned on, the powder is mixed into an aqueous carrier. The powder may be any hydrated insoluble compound such as, but not limited to, sodium borate decahydrate or alumina trihydrate. In this case, the inventors used a combination of alumina trihydrate and magnesia, and in a second example sodium bo...

Embodiment 2

[0231] Preparation of sliver incorporating individual fibers associated with metals and metal oxides

[0232] The sliver is prepared such that it has a low twist (about 4 twists per meter) and weighs 3 to 8 grams per meter. The sliver may be made from any staple fiber such as, but not limited to, cotton, rayon, polyester or nylon. The sliver is run through the system as described, but before the sliver is placed in the channel of the belt, a very small amount of the intended compound in the form of a fine powder (typically no larger than 5 microns in size) is placed in the water and the chemical delivery tank (32) or placed on a dry belt. The powder should be zinc or any form of zinc, such as zinc oxide, but in a preferred embodiment should be zinc oxide at a purity level of not less than 97%. Other metals and metal oxides may be used, such as copper and / or its oxides or silver and / or its oxides. The amount of predetermined chemical compound is not critical, since the fiber...

Embodiment 3

[0244] Embodiment 3 (diatomaceous earth and organic insoluble compound)

[0245] The sliver is prepared so that it has a low twist (about 4 twists per meter) and weighs from about 2 to about 20 grams per meter, and preferably from about 3 to about 8 grams per meter. The sliver can be made from any staple fiber such as, but not limited to, cotton, rayon, polyester and nylon. The sliver is run through the system as described, but before the sliver is placed in the channel of the belt, a very small amount of the intended compound in the form of a fine powder (typically no larger than 5 microns in size) is placed in the water and the chemical delivery tank (32) or placed on a dry belt. The powder can be food grade diatomaceous earth with a purity level of not less than 97%. Diatomaceous earth was chosen for this example because it is EPA-approved as an insecticide for use against common bed bugs, temperate bed bugs (Cimexlectularius), and other exoskeletal pests such as fleas, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com