High uniformly dispersed cobalt disulfide/graphene composite material and preparation method thereof

A uniformly dispersed, cobalt disulfide technology, used in the manufacture of hybrid/electric double layer capacitors, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of cobalt disulfide nanoparticle dispersion is not very ideal problem, to achieve the effect of strong repeatability, good repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

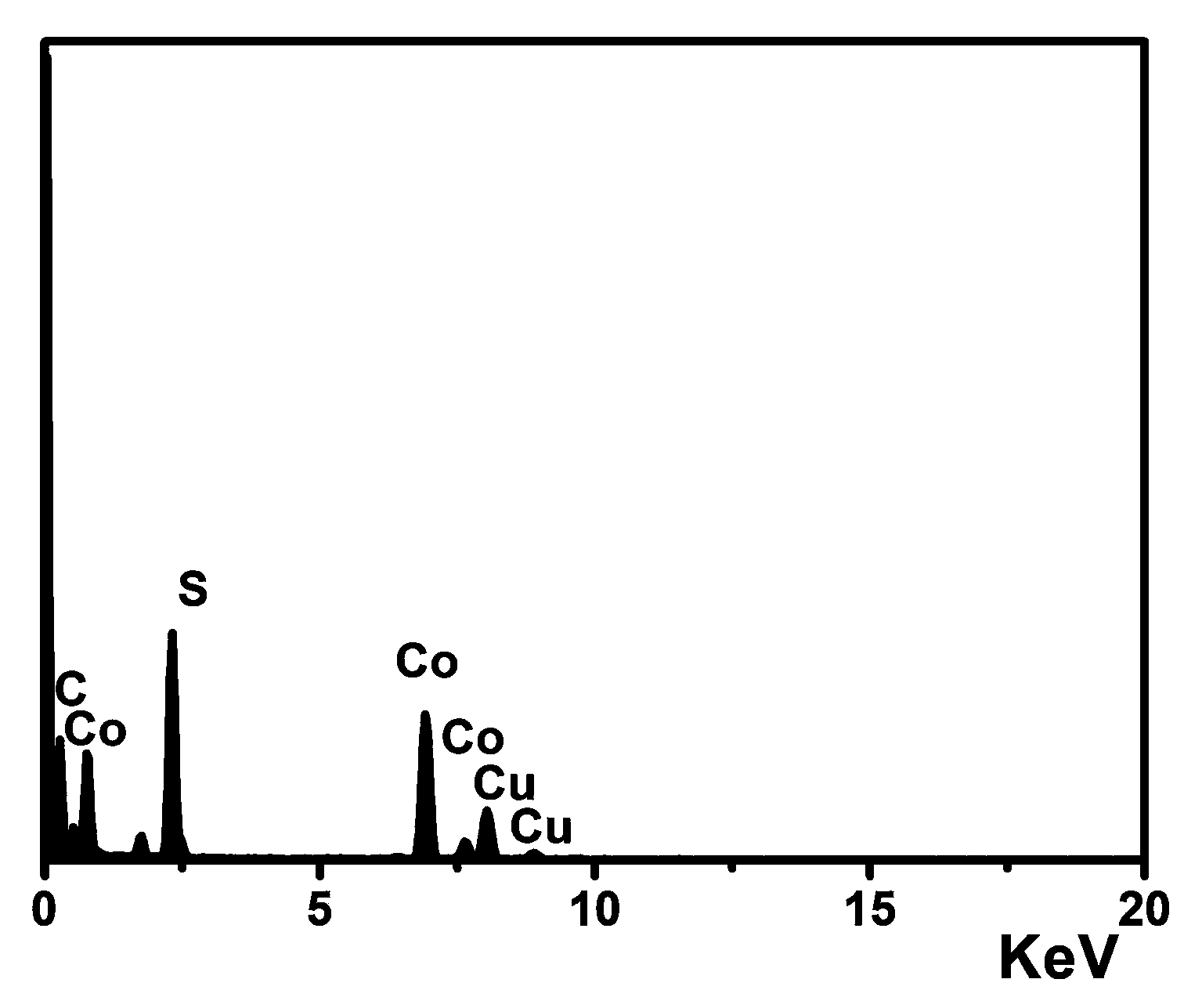

[0022] Take 10 mg of graphene oxide, add 60 mL of distilled water, add 0.05 g of surfactant F127, add 1 mmol of cobalt nitrate, then add 1 mmol of sodium thiosulfate, then add 0.1 g of ascorbic acid and stir until completely dissolved, then transfer to 100 mL of polytetrafluoroethylene Calcined at 120°C for 6h in a lined hydrothermal reactor, cleaned the sample, and dried in vacuum at 30°C to obtain the final product. Such as figure 1 As shown, the synthesized composites contain S, Co, and C elements.

Embodiment 2

[0024] Take 20mg of graphene oxide, add 64mL of distilled water, add 0.1g of surfactant F127, add 3mmol of cobalt nitrate, then add 2mmol of sodium thiosulfate, then add 0.3g of ascorbic acid and stir until completely dissolved, then transfer to 100mL of polytetrafluoroethylene Calcined at 140°C for 10 h in a lined hydrothermal reactor, cleaned the sample, and dried in vacuum at 35°C to obtain the final product.

Embodiment 3

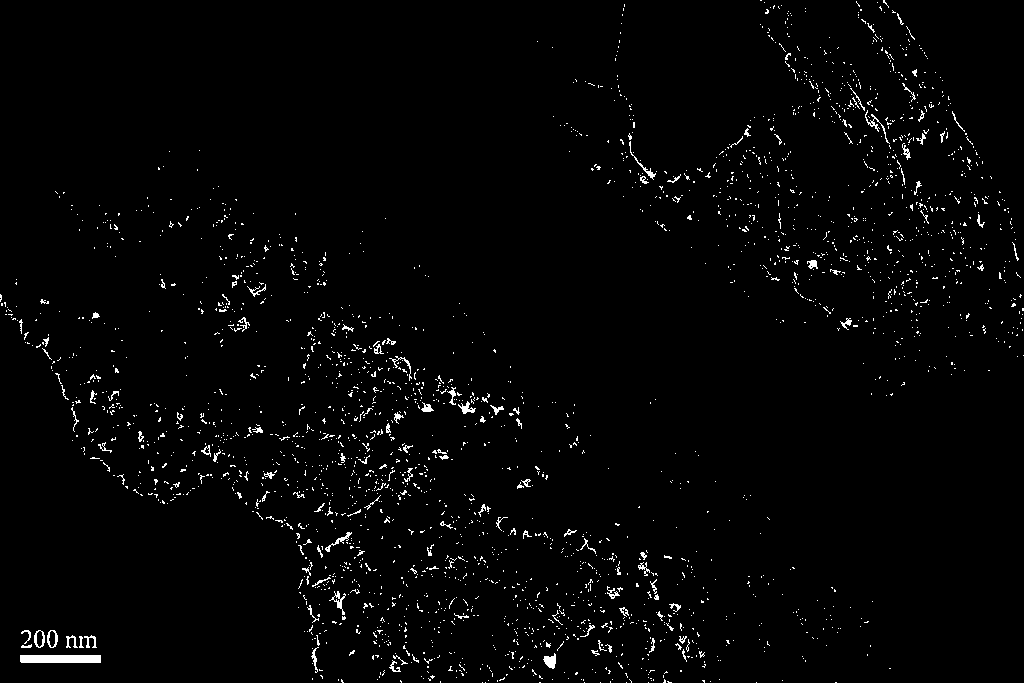

[0026] Take 30mg of graphene oxide, add 68mL of distilled water, add 0.2g of surfactant F127, add 5mmol of cobalt chloride, then add 3mmol of sodium thiosulfate, then add 0.4g of ascorbic acid and stir until completely dissolved, then transfer to 100mL of polytetrafluoroethylene Calcined at 160°C for 12 hours in an ethylene-lined hydrothermal reactor, cleaned the sample, and dried in vacuum at 40°C to obtain the final product. From figure 2 It can be seen from the transmission electron microscope pictures that cobalt disulfide is evenly distributed on the graphene, and the particle size is about 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com