Realization method of relay driving module applied to elevator control system

An implementation method and technology of driving modules, which are applied in the direction of relays, circuits, electrical components, etc., can solve the problems of effective level, relay K1 malfunction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. Control signal

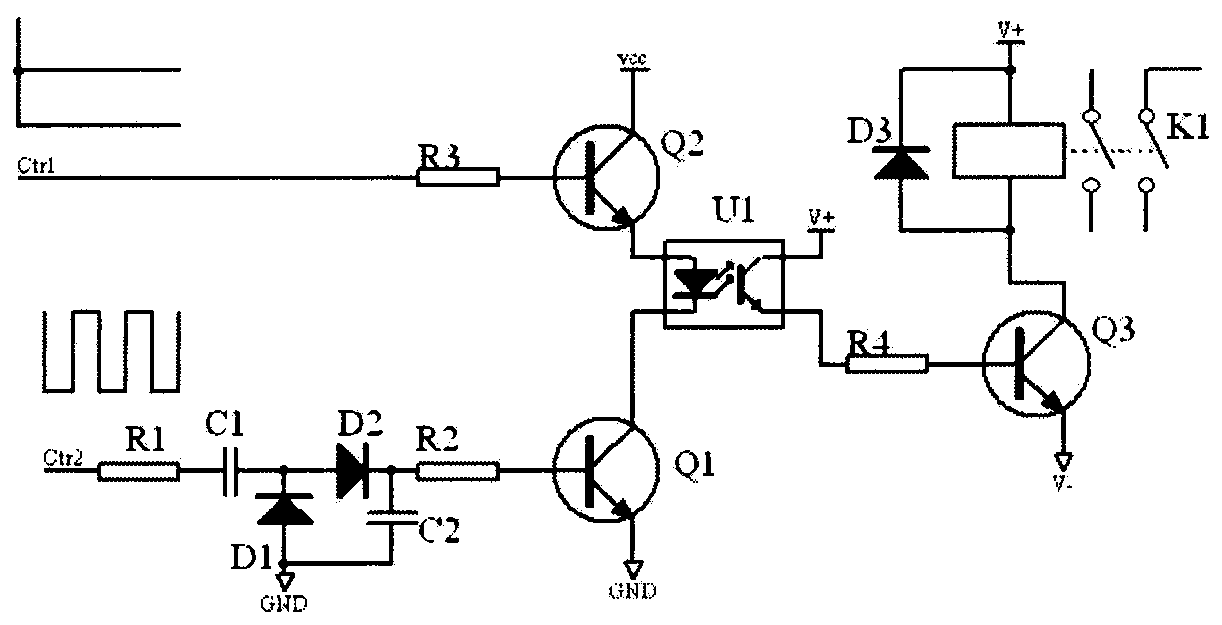

[0012] Such as figure 2 As shown, the effective signal of the control terminal Ctr1 is a level signal (the circuit is active at high level), and the effective signal of the control terminal Ctr1 is a signal with adjustable pulse width. When both the control terminal Ctr1 and the control terminal Ctr2 are valid signals, the relay coil is connected to both ends of the power supply to generate a driving current, and the relay operates.

[0013] 2. Conversion circuit

[0014] Such as figure 2 As shown, the level signal of the control terminal Ctr1 is connected to the base of the triode Q2 through the current limiting resistor R3, and the conduction between the input terminal of the optocoupler U1 and the power supply vcc is controlled by a meter; the pulse width adjustable square wave signal of the control terminal Ctr2 is limited The current resistor R1 and the DC blocking capacitor C1 are filtered by the capacitor C2 and then converted into a leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com