Dehydroacetic acid (DHA) feed additive prepared from kitchen waste and preparation method thereof

A docosahexaenoic acid and kitchen waste technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, applications, etc., can solve the problems of reducing the production cost of the medium and the effect is not significant, and achieve product additional High value, no need for organic reagent extraction, high DHA content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

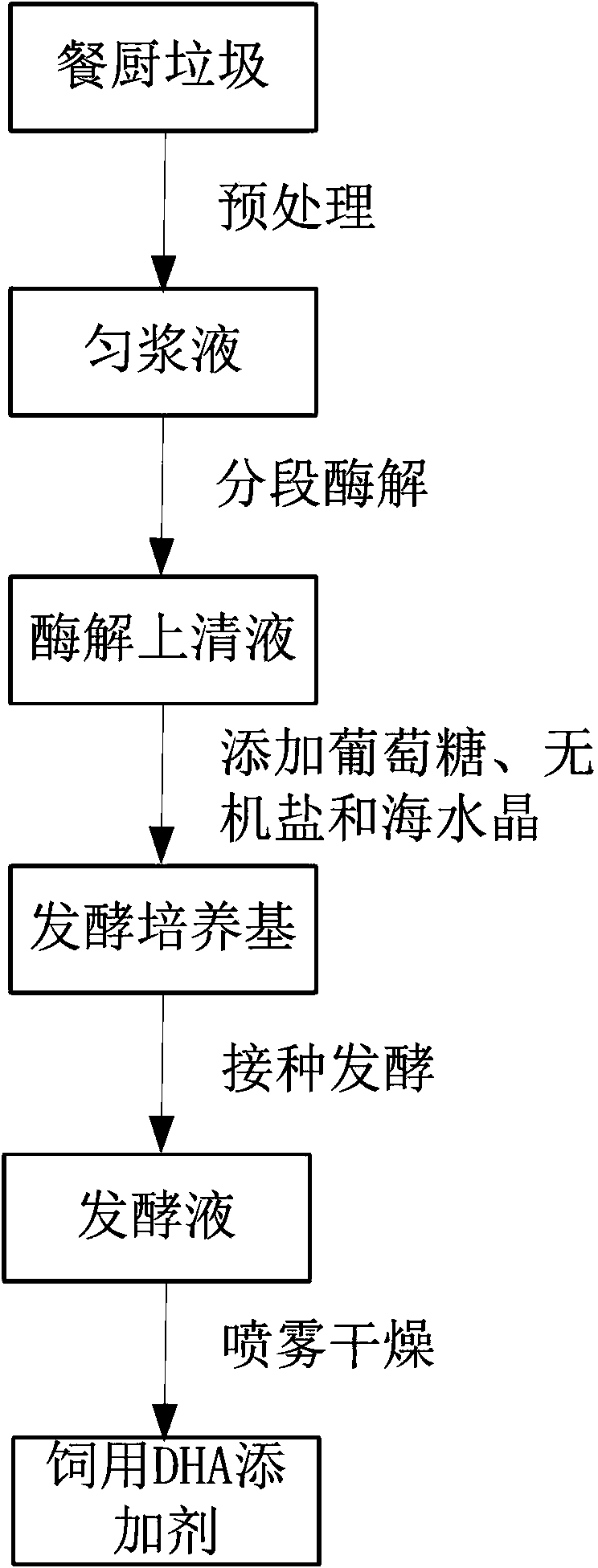

Method used

Image

Examples

Embodiment 1

[0068] (1) Pretreatment: collect fresh and undeteriorated food waste from the canteen of a scientific research unit in the south, and manually assist machines to remove inorganic or refractory debris such as glass, ceramics, plastics, metals, bones, and toothpicks, and obtain the after-cleaning waste. kitchen waste; the food waste is pulverized with a food tissue grinder, diluted with water at a volume ratio of 1:1, and homogenized with a homogenizer to obtain a homogenate, so that the particle size of the material in the homogenate is within Below 5mm;

[0069] The moisture content of the food waste used this time is 72.1%, TS is 13.8%, VS / TS is 86.4%, salt content is 1.51%, and the chemical composition of the food waste is 23.4% total sugar and 27.7% protein on a dry basis , crude fat 19.4%, crude fiber 7.5%, ash 9.3%.

[0070] (2) Segmented enzymatic hydrolysis: heat the homogenate in step (1) to 80°C, add α-amylase 15U / (g kitchen waste), and enzymatically hydrolyze for 10...

Embodiment 2

[0079] (1) Pretreatment: collect fresh and undeteriorated food waste from the canteen of a scientific research unit in the south, and manually assist machines to remove inorganic or refractory debris such as glass, ceramics, plastics, metals, bones, and toothpicks, and obtain the after-cleaning waste. kitchen waste; use a food tissue grinder to pulverize the food waste, dilute it with water at a volume ratio of 1:2, and use a homogenizer to obtain a homogenate, so that the particle size of the material in the homogenate is within Below 10mm;

[0080] The moisture content of the food waste used this time is 63.3%, TS is 17.4%, VS / TS is 92.6%, salt content is 1.21%, and the chemical composition of the food waste is 44.3% of total sugar and 20.1% of protein on a dry basis. , crude fat 9.7%, crude fiber 5.9%, ash 8.5%.

[0081] (2) Segmented enzymatic hydrolysis: heat the homogenate to 70°C, add α-amylase 8U / (g kitchen waste), and enzymolyze for 80 minutes to obtain the first enz...

Embodiment 3

[0090] (1) Pretreatment: collect fresh and undeteriorated food waste from the canteen of a scientific research unit in the south, and manually assist machines to remove inorganic or refractory debris such as glass, ceramics, plastics, metals, bones, and toothpicks, and obtain the after-cleaning waste. kitchen waste; use a food tissue grinder to pulverize the food waste, dilute it with water at a volume ratio of 1:1, and use a homogenizer to obtain a homogenate, so that the particle size of the material in the homogenate is within Below 10mm;

[0091] The moisture content of the food waste used this time is 63.3%, TS is 17.4%, VS / TS is 92.6%, salt content is 1.21%, and the chemical composition of the food waste is 44.3% of total sugar and 20.1% of protein on a dry basis. , crude fat 9.7%, crude fiber 5.9%, ash 8.5%.

[0092] (2) Segmented enzymatic hydrolysis: heat the homogenate to 90°C, add α-amylase 18U / (g kitchen waste), and perform enzymatic hydrolysis for 60 minutes to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com