Energy recovery control method of double-planet-row four-axis hybrid power system

A technology of a hybrid power system and a double planetary row is applied in the field of energy recovery control of a double planetary row four-shaft hybrid power system, which can solve the problems of poor energy recovery effect, low motor torque, small motor torque, etc., so as to improve the energy recovery efficiency. , to avoid the effect of high speed and low torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

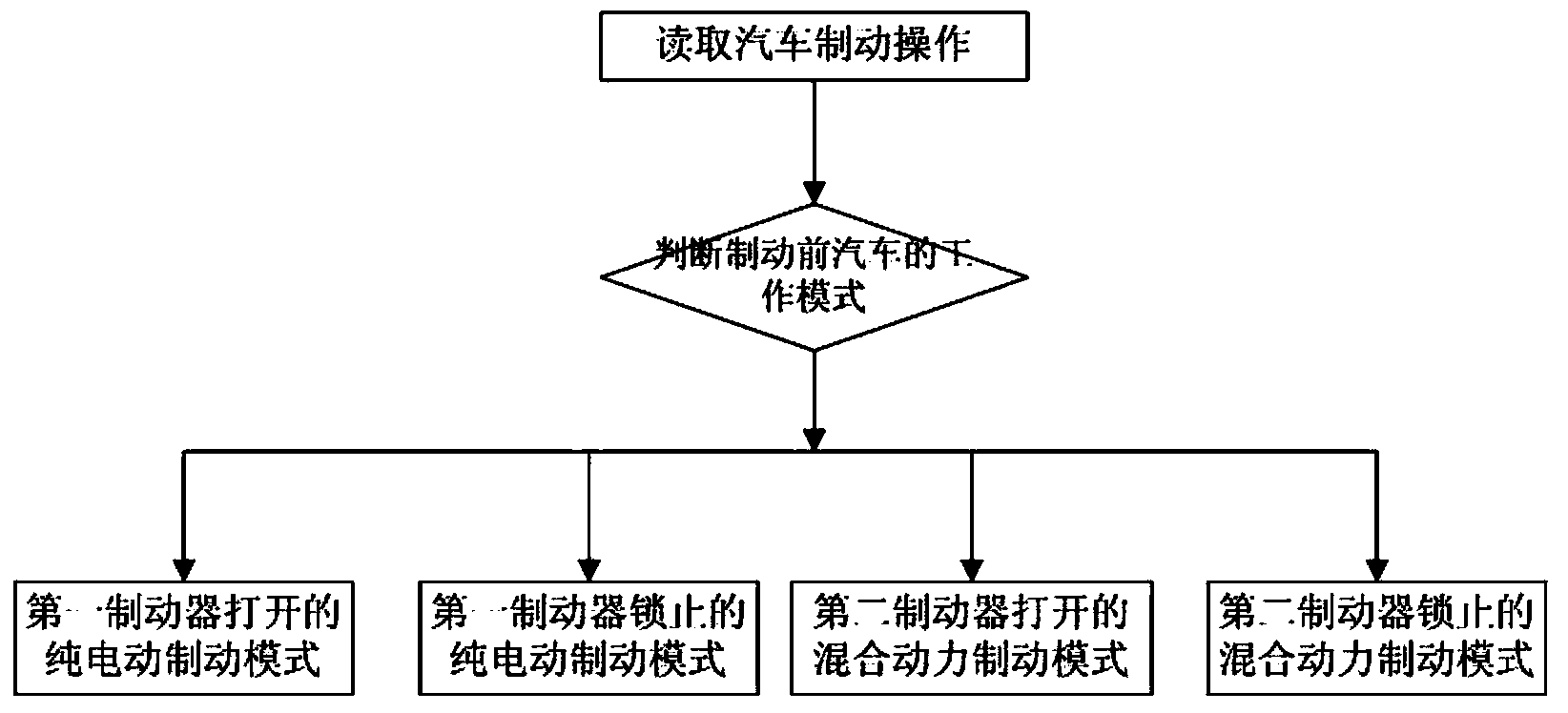

[0046] Embodiment: The energy recovery control method of a dual-planetary four-shaft hybrid system in this embodiment, such as figure 1 shown, including the following steps:

[0047] S1: When the car brakes, if the car is in the pure electric running mode and the first brake is in the open state before braking, then perform step S2, if the car is in the pure electric running mode and the first brake is in the locked state before braking, Then execute step S3, if the vehicle is in the hybrid operation mode before braking and the second brake is in the open state, then perform step S4, if the vehicle is in the hybrid operation mode before braking and the second brake is in the locked state, then perform step S4 S5;

[0048] S2: The brake control unit obtains the braking torque TH required by the current car according to the current brake pedal opening BPS and the current vehicle speed V look-up table and sends it to the vehicle control unit. The motor controller sets the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com