Production apparatus for aluminium oxide catalyst carrier

A catalyst carrier and production device technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, catalyst activation/preparation, etc., can solve the problems of insufficient heat exchange, uneven stirring, single function, etc., to achieve convenient control and increase stirring method, the effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

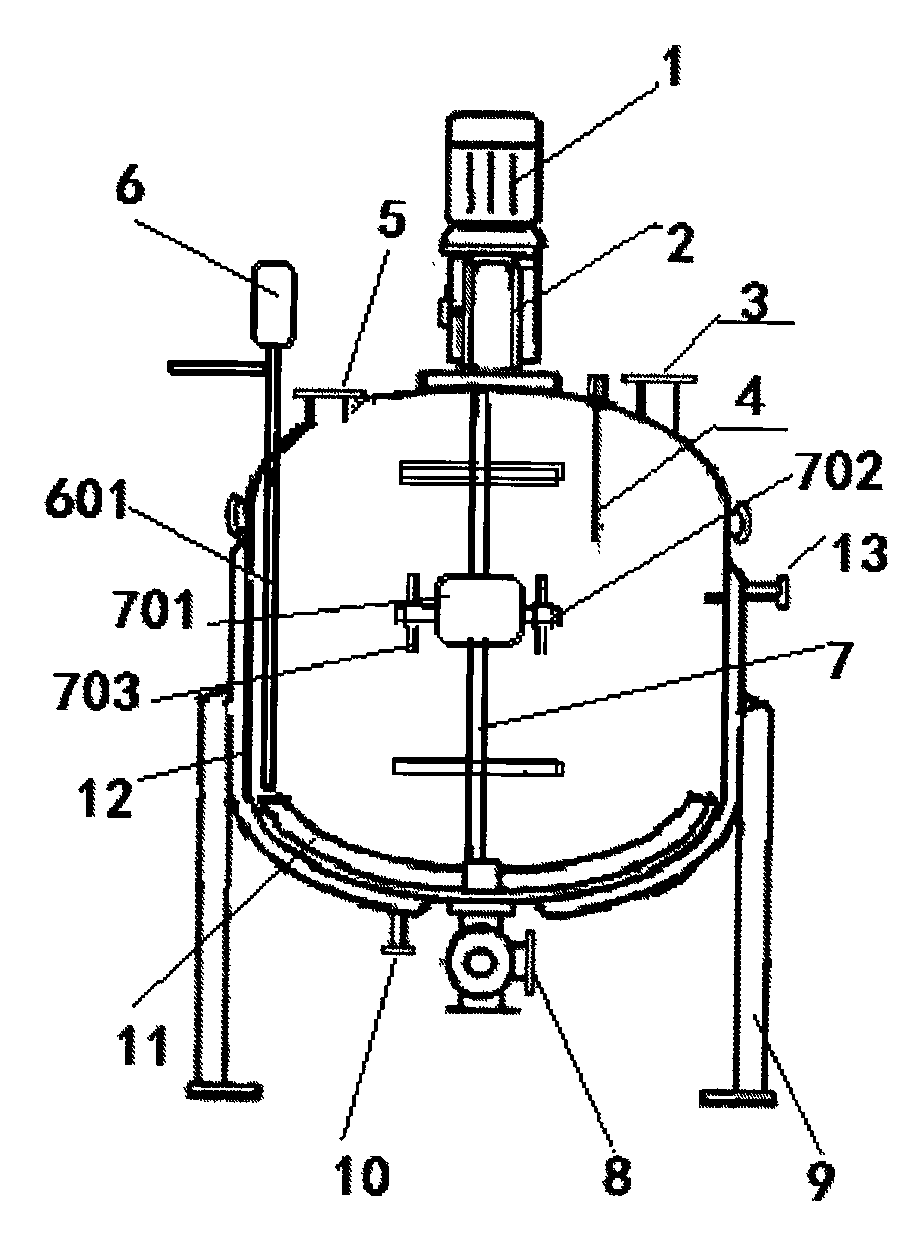

[0012] As shown in the accompanying drawings, an alumina catalyst carrier production device includes a kettle body, which is equipped with a motor 1, a reducer 2, a feed pipe a3, a safety valve 4, a feed pipe b5, an agitator 7, an outlet Material inlet 8, legs 9, heat outlet pipe 10, heating interlayer 12, heat inlet pipe 13, characterized in that the kettle body is provided with a sampler 6, the sampler 6 is arranged above the kettle body, the sampler 6 and the kettle body There is a sealing cover between them; a stirrer 11 at the bottom of the kettle is arranged on the stirrer 7 in the kettle body, the stirrer 11 at the bottom of the kettle is arranged at the lowermost end of the stirrer 7, and a roller is arranged between the stirrer 11 at the bottom of the kettle and the bottom of the kettle.

[0013] As a further improvement of the present invention, the middle position of the agitator 7 is provided with a diverter 701, the diverter 701 is provided with a transverse stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com