Long-acting high-brightness light-reflection sheet and preparation method thereof

A reflective sheeting and high-brightness technology, applied in the field of reflective sheets, can solve the problems of limited application occasions and the inability of reflective sheets to work, and achieve the effect of prolonging the service life and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a long-lasting high-brightness reflective sheet, the steps comprising:

[0028] ①Aluminum steaming: evaporate nano-aluminum in an oxygen-free environment at a temperature of 1500°C and attach it to the front of the PVC base layer to form a reflective layer;

[0029] ② Coating: Mix 100 parts of transparent polyester resin, 15-20 parts of luminous microcapsules, 5 parts of anti-settling agent, and 5 parts of diluent at a temperature of 200-220 ° C, and then evenly coat Distributed on the outer surface of the reflective layer, cooled to form a fluorescent layer;

[0030] ③ Coating: A layer of anti-oxidation film is covered on the fluorescent layer as a protective layer.

Embodiment 1

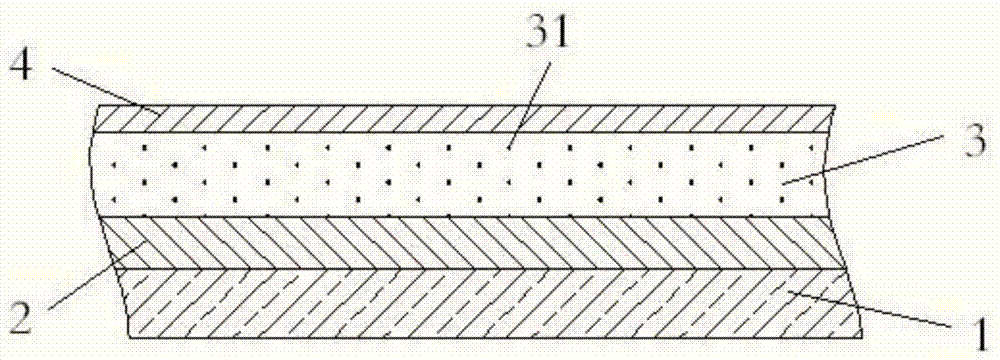

[0033] ① Evaporate nano-aluminum in an oxygen-free environment at a temperature of 1500°C and attach it to the front of the PVC base layer 1 to form a reflective layer 2;

[0034] ②Mix 100 parts by mass of transparent polyester resin, 15 parts by mass of luminous microcapsules 31, 5 parts by mass of anti-settling agent, and 5 parts by mass of diluent at a temperature of 220°C, and then evenly coat it on the outside of the reflective layer 2 The surface is cooled to form a fluorescent layer 3;

[0035] ③ Cover the fluorescent layer 3 with an anti-oxidation film as the protective layer 4 .

[0036] refer to figure 1 The reflective sheet includes a PVC base layer 1, a nano-aluminum reflective layer 2 located on the front of the base layer 1, a fluorescent layer 3 containing luminous microcapsules 31 located on the outer surface of the reflective layer 2, and an anti-oxidation protective layer coated on the outer surface of the fluorescent layer 3 4.

[0037] Since the main com...

Embodiment 2

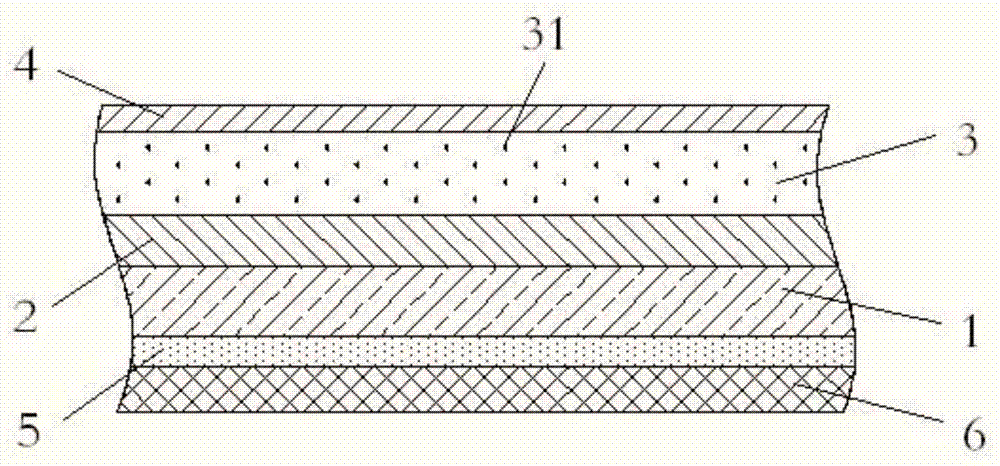

[0039] ① Paste the pressure-sensitive adhesive 5 with the release paper 6 as the substrate on the back of the PVC base layer 1;

[0040] ② Evaporate nano-aluminum in an oxygen-free environment at a temperature of 1500°C and attach it to the front of the base layer 1 to form a reflective layer 2;

[0041] ③ Mix 100 parts by mass of transparent resin, 20 parts by mass of luminous microcapsules 31, 5 parts by mass of anti-settling agent, and 5 parts by mass of diluent at a temperature of 200°C, and then evenly coat the outer surface of the reflective layer 2, cooling to form the fluorescent layer 3;

[0042] ④ Cover the fluorescent layer 3 with an anti-oxidation film as the protective layer 4 .

[0043] refer to figure 2 , The difference from Example 1 is that the back of the reflective sheet has a pressure-sensitive adhesive 5, and the release paper 6 can be torn off during use to attach the reflective sheet to the surface of the object that needs to be marked, which is conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com