Slurry transmitting pump under vertical magnetic driving multiple sealing liquid

A magnetic drive, multiple sealing technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of large vibration and noise of the pump, affecting personal safety, pump loss, etc., to improve the sealing effect and safety performance, improved stability and reliability, and reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

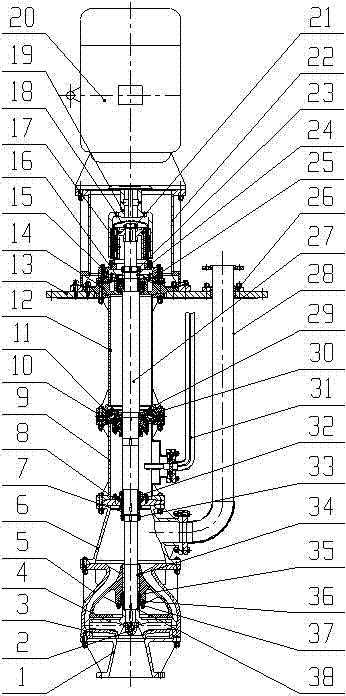

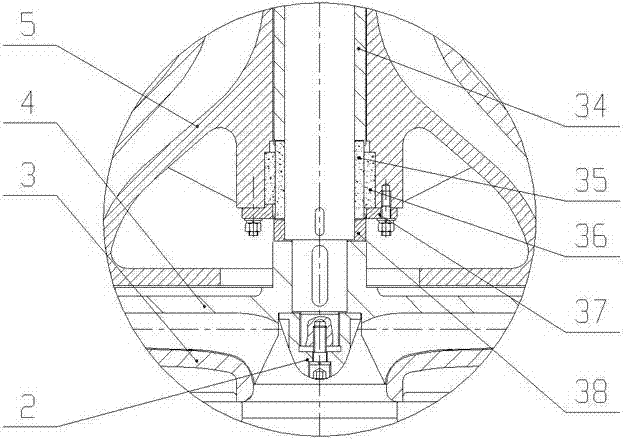

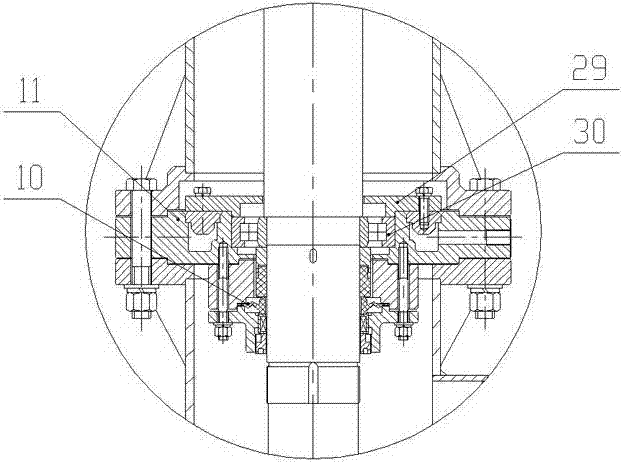

[0016] A vertical magnetic drive multi-seal submerged slurry delivery pump, including a leak detection tube 9, a motor 20, and a pump shaft 27, the motor 20 is installed on a motor frame 22, a mounting plate 13 is arranged below the motor frame 22, and the output shaft of the motor 20 It is connected with the outer magnetic rotor assembly 19; the outer magnetic rotor assembly 19 is sequentially provided with a spacer 18, an inner magnetic rotor assembly 17, and a pump shaft 27 from outside to inside, and the upper end of the pump shaft 27 is locked with the inner magnetic rotor assembly 17, and the spacer sleeve 18 is installed on the spacer seat 15, and the upper bearing seat assembly 14 is arranged below the spacer seat 15, and the upper bearing seat assembly 14 is installed on the upper end surface of the mounting plate 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com