Automatic hole punching piling machine control system aiming at complicated terrains

A technology of automatic punching and complex terrain, applied in the direction of digital control, electrical program control, sheet pile wall, etc., can solve the problems of piling failure, piling efficiency reduction, suction hammer, etc., to improve system reliability and stability, save Operation time, the effect of increasing the acquisition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

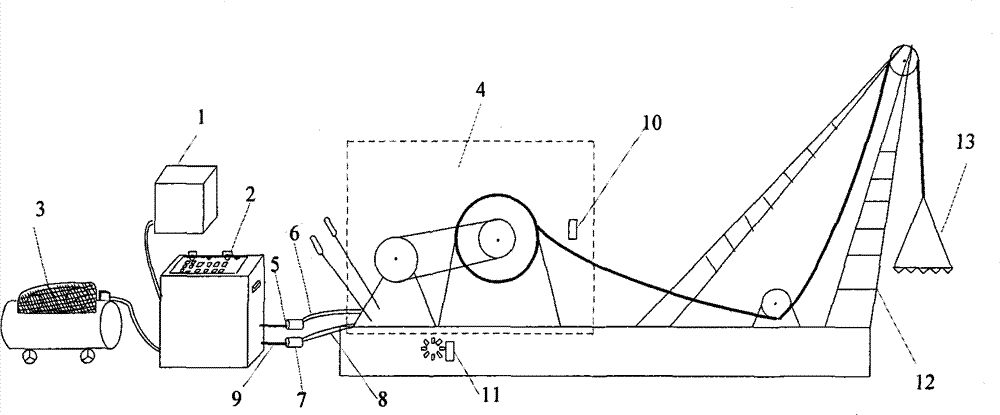

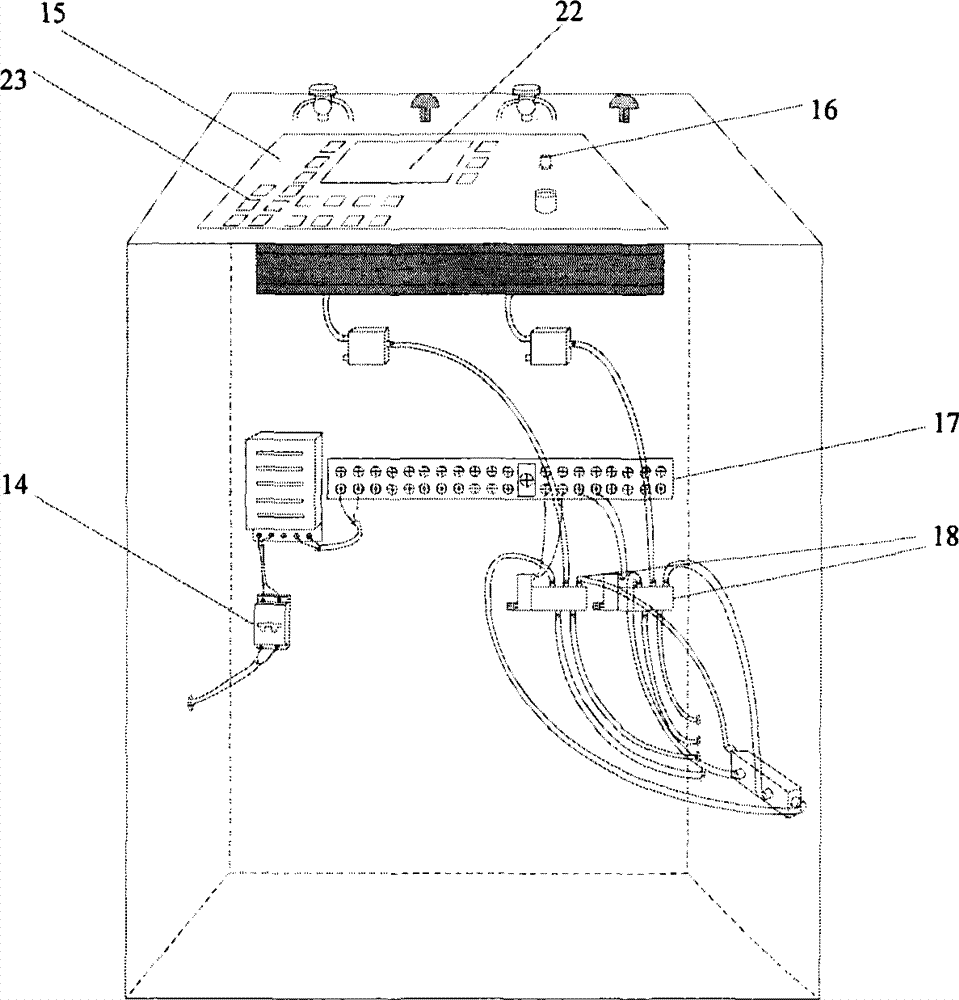

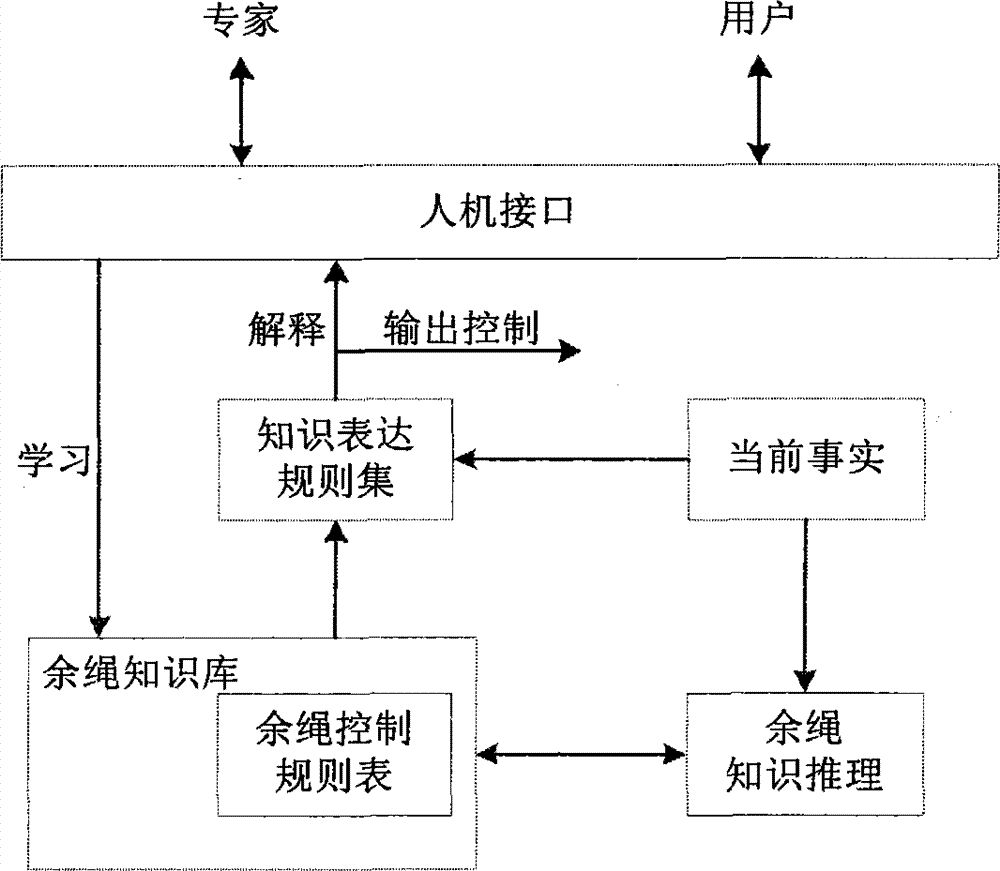

[0027] An automatic punching piling machine control system for complex terrain, which consists of a power distribution cabinet 1, a control cabinet 2, an air compressor 3, a winch 4, a brake cylinder 5, a brake lever 6, a clutch cylinder 7, a clutch lever 8, Air pipe 9, height sensor 10, stuck hammer sensor 11, pile frame 12, pile hammer 13, it is characterized in that, the automatic punching pile driver control system for complex terrain also includes: fast Fourier transform system, residual Rope optimal control algorithm system and remaining rope expert control system;

[0028] The power distribution cabinet 1 is connected with the control cabinet 2, the air compressor 3, and the hoist 4 to provide power for the entire system; the air compressor 3, the control cabinet 2, the brake cylinder 5, the brake lever 6, and the clutch cylinder 7 , the clutch joystick 8 is connected through the air pipe 9 to form the pneumatic part of the control system; the control cabinet 2 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com