Fluorescence-free anti-collapse agent applied to drilling fluid

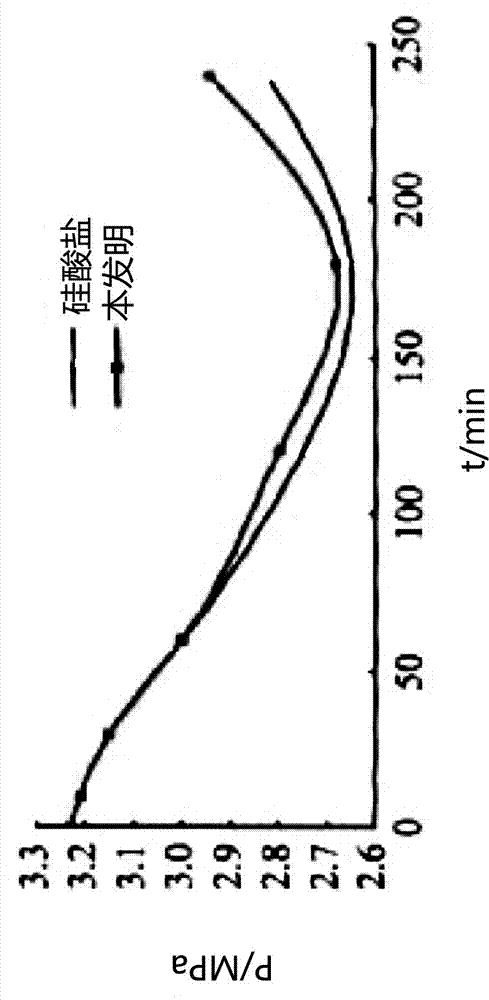

A non-fluorescent, anti-slump agent technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased drilling fluid viscosity, high fluorescence level, inconvenient use, etc., and achieve the effect of retarding pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment one: preparation.

[0013] Stir the PVA solution with a pH value of 9 in a water bath at 80°C for 10 minutes at a constant temperature, add a catalyst and a strong oxidant under stirring conditions, continue to stir at a constant temperature for 1.5 hours, then adjust the pH value to 8, and stir at a constant temperature in a water bath at 60°C for 10 minutes. Minutes, add cationization reagent under stirring condition, continue to stir at constant temperature for 3 hours, cool to room temperature; After washing 3 times and vacuum drying, a white solid granular modified polyvinyl alcohol is obtained, which is a non-fluorescent anti-slump agent for drilling fluid.

Embodiment 2

[0014] Embodiment 2: adsorption test.

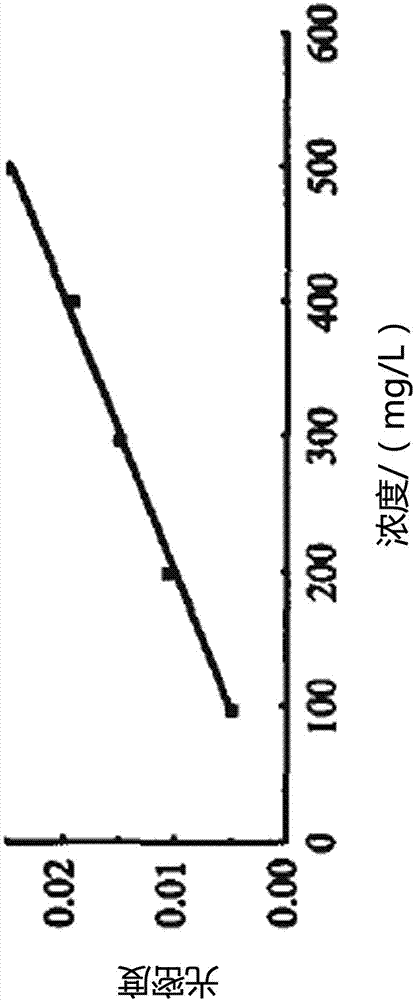

[0015] The invention can generate stable blue ternary complexes with concentrated cobalt thiocyanate salt, and the color depth of the ternary complexes is different with different concentrations. According to Bill Lambert's law, the optical density at different concentrations was measured with a spectrophotometer (wavelength set at 550 nnl), and a working curve was drawn. The results are shown in Figure 1. Measure the optical density of the present invention after being adsorbed on clay particles at room temperature, find out the corresponding concentration from the working curve, and calculate the adsorption amount. When the concentration is 0.5% and 1%, the adsorption capacity is 80.8, 115.8 mg / g, and the shale rolling recovery rate is 72.72%, 85.88%, respectively. It can be seen that the higher the concentration of the present invention, the greater the adsorption capacity, the higher the recovery rate, and the stronger the ability t...

Embodiment 3

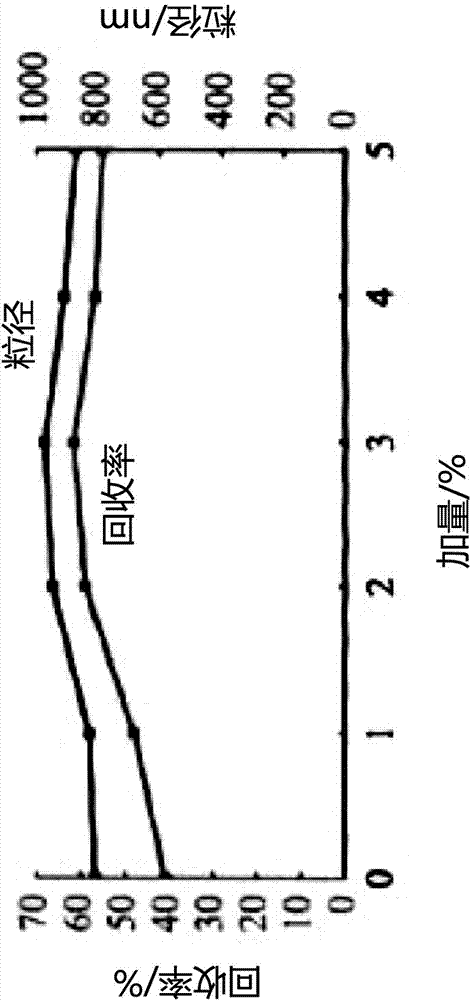

[0016] Embodiment 3: The influence of the present invention on the particle size distribution of shale.

[0017] Utilize particle size analyzer to measure the particle size distribution of the shale particles before and after the action of the present invention and shale, as figure 2 shown. From figure 2 It can be seen that with the increase of the dosage of the present invention, the particle size of the shale first increases and then gradually decreases, which is consistent with the change trend of the rolling recovery rate of the shale under the corresponding dosage. Its reason is: along with the increase of the concentration of the present invention, its adsorption on the particle surface increases, and when the concentration increases to a certain extent, because the electrostatic repulsion hinders the adsorption of the molecule of the present invention on the particle surface, the adhesion of the particle in the medium is enhanced. dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com