Preparation and application method of a strippable cellulose-based radioactive contamination decontamination agent

A cellulose-based, detergent technology, applied in radioactive purification, coating, nuclear engineering, etc., can solve the problems of refractory waste degradation, unfavorable environmental sustainable development, secondary pollution, etc., and achieve abundant resources and easy storage Curing treatment, the effect of high capacity reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of a strippable cellulose-based radioactive contamination remover, wherein the method comprises the following steps:

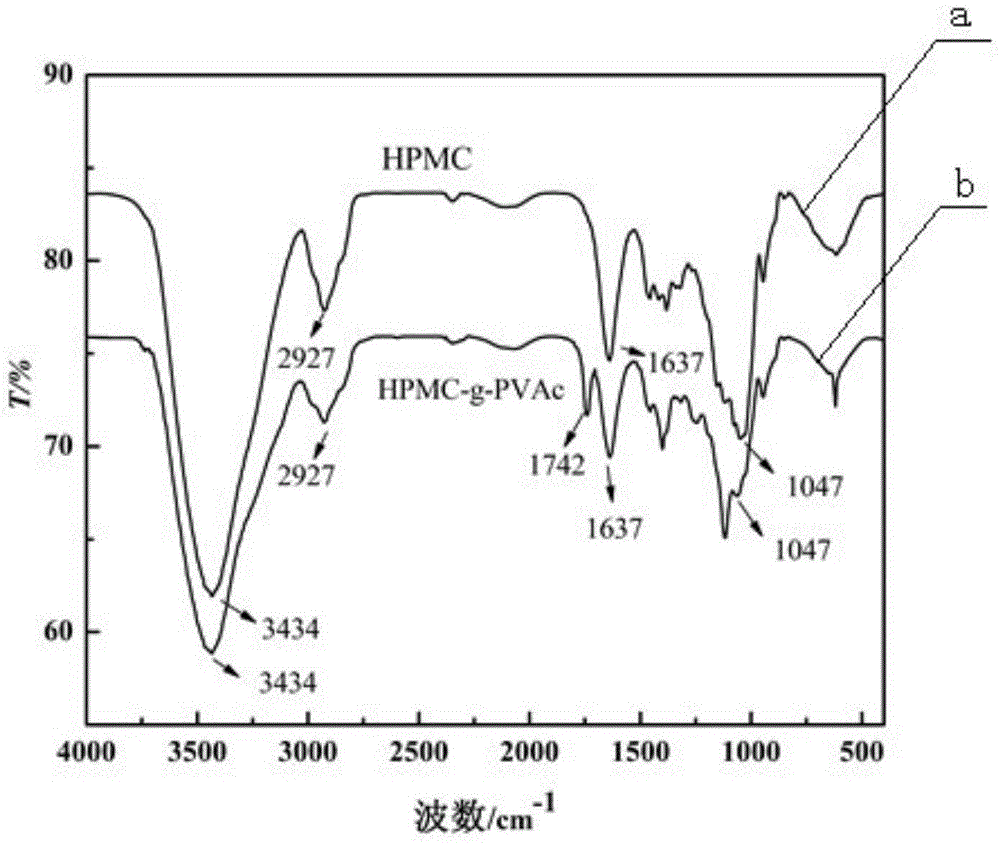

[0038] Step a, modifying the pre-prepared cellulose ether by grafting:

[0039] Add 2-8 parts by weight of cellulose ether to 80-150 parts by weight of distilled water, and heat in a water bath under the premise of passing through a protective gas until the temperature reaches 60-80 ° C, then stir for 10-30 minutes, and then sequentially Add 0.05-0.30 parts by weight of initiator and stir for 10-30 minutes and 2-8 parts by weight of vinyl acetate monomer to react for 3-6 hours, and the resulting mixture is centrifuged and dried under vacuum at 45-65°C The crude product is obtained in 10-14 hours; the crude product is crushed and placed in a Soxhlet extractor and extracted with acetone for 22-26 hours to obtain a cellulose ether grafted product;

[0040] Here, when vinyl acetate monomer is added for reaction, ...

Embodiment 1

[0050] The graft modification of step a, hydroxypropyl methylcellulose:

[0051] Add 2 parts by weight of hydroxypropyl methylcellulose to 80 parts by weight of distilled water, pass through nitrogen protection, heat in a water bath to 60°C, stir for 10 minutes, add 0.10 parts by weight of ammonium persulfate and stir for 10 minutes, then add 2 parts by weight of Parts of vinyl acetate monomer were reacted under nitrogen protection at 60°C for 6 hours, centrifuged, and vacuum-dried at 45°C for 12 hours to obtain a crude product, which was pulverized in a Soxhlet extractor and extracted with acetone for 24 hours to obtain Remove the hydroxypropyl methylcellulose graft copolymerized vinyl acetate product of by-product;

[0052] Step b, utilize the obtained hydroxypropyl methylcellulose graft copolyvinyl acetate product to prepare detergent: at room temperature, 2 parts by weight of hydroxypropyl methylcellulose graft copolyvinyl acetate product are dissolved in 80 In the aqueou...

Embodiment 2

[0056] The graft modification of step a, hydroxypropyl methylcellulose:

[0057] Add 3 parts by weight of hydroxypropyl methylcellulose to 100 parts by weight of distilled water, pass through nitrogen protection, heat in a water bath to 80°C, stir for 15 minutes, add 0.15 parts by weight of ammonium persulfate and stir for 15 minutes, then add 3 parts by weight of Parts of vinyl acetate monomer were reacted under nitrogen protection at 80°C for 5 hours, centrifuged, and vacuum-dried at 60°C for 12 hours to obtain the crude product, which was pulverized in a Soxhlet extractor and extracted with acetone for 24 hours to obtain Remove the hydroxypropyl methylcellulose graft copolymerized vinyl acetate product of by-product;

[0058] Step b, utilize the obtained hydroxypropyl methylcellulose graft copolyvinyl acetate product to prepare detergent: at room temperature, 4 parts by weight of hydroxypropyl methylcellulose graft copolyvinyl acetate product are dissolved in 96 In the wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com