A drum turning and unloading device

A technology of dumping device and drum, which is applied in the field of drum turning and dumping device, which can solve the problems of powdery material remaining at the bottom of the drum, high labor intensity, and difficulty of dumping, so as to avoid residue, reduce labor intensity, The effect of improving the efficiency of dumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

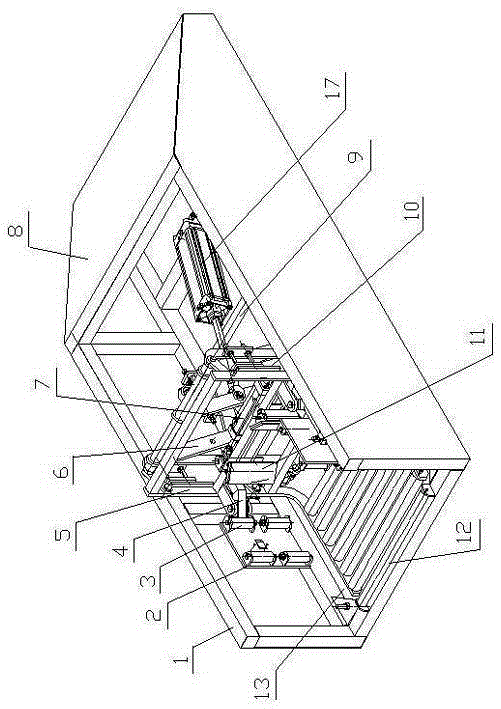

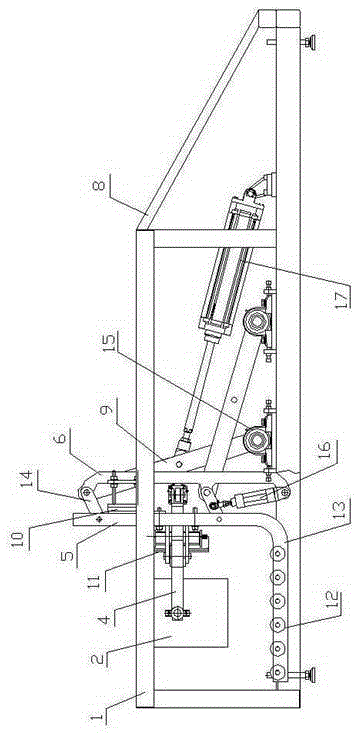

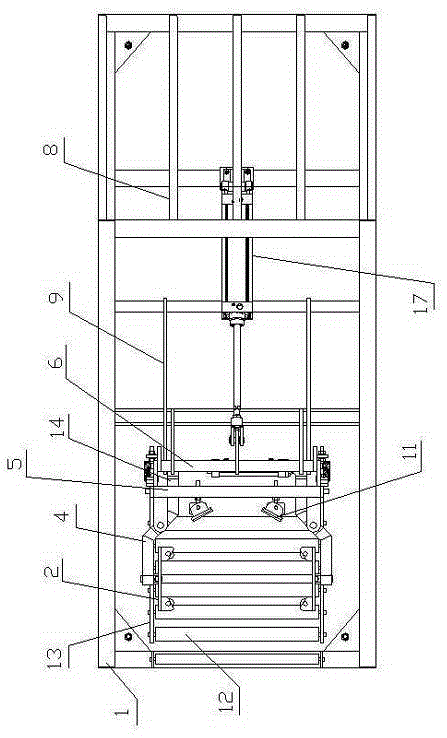

[0017] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0018] refer to Figure 1-3 , a drum turning and unloading device, is provided with a fixed frame 1, the front end of the fixed frame 1 is the drum inlet, and the rear end of the fixed frame 1 is provided with a material dumping platform 8 inclined from front to back downwards, the material dumping platform The fixed frame 1 between 8 and the drum inlet is provided with an overturning mechanism, and the overturning mechanism is provided with an overturning working surface 6, and the overturning working surface 6 is provided with a drum fixing device. Equipped with a reciprocating impact mechanism;

[0019] Described drum fixing device comprises bottom support 13, backboard 5 and two jaws of fixed drum, and jaw is arranged symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com