Full-closed loop electro-hydraulic servo plate bending machine

An electro-hydraulic servo and bending machine technology, applied in the field of bending machine devices, can solve the problems of energy waste, hydraulic oil overflow, etc., and achieve the effects of reducing energy consumption, reducing overflow, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

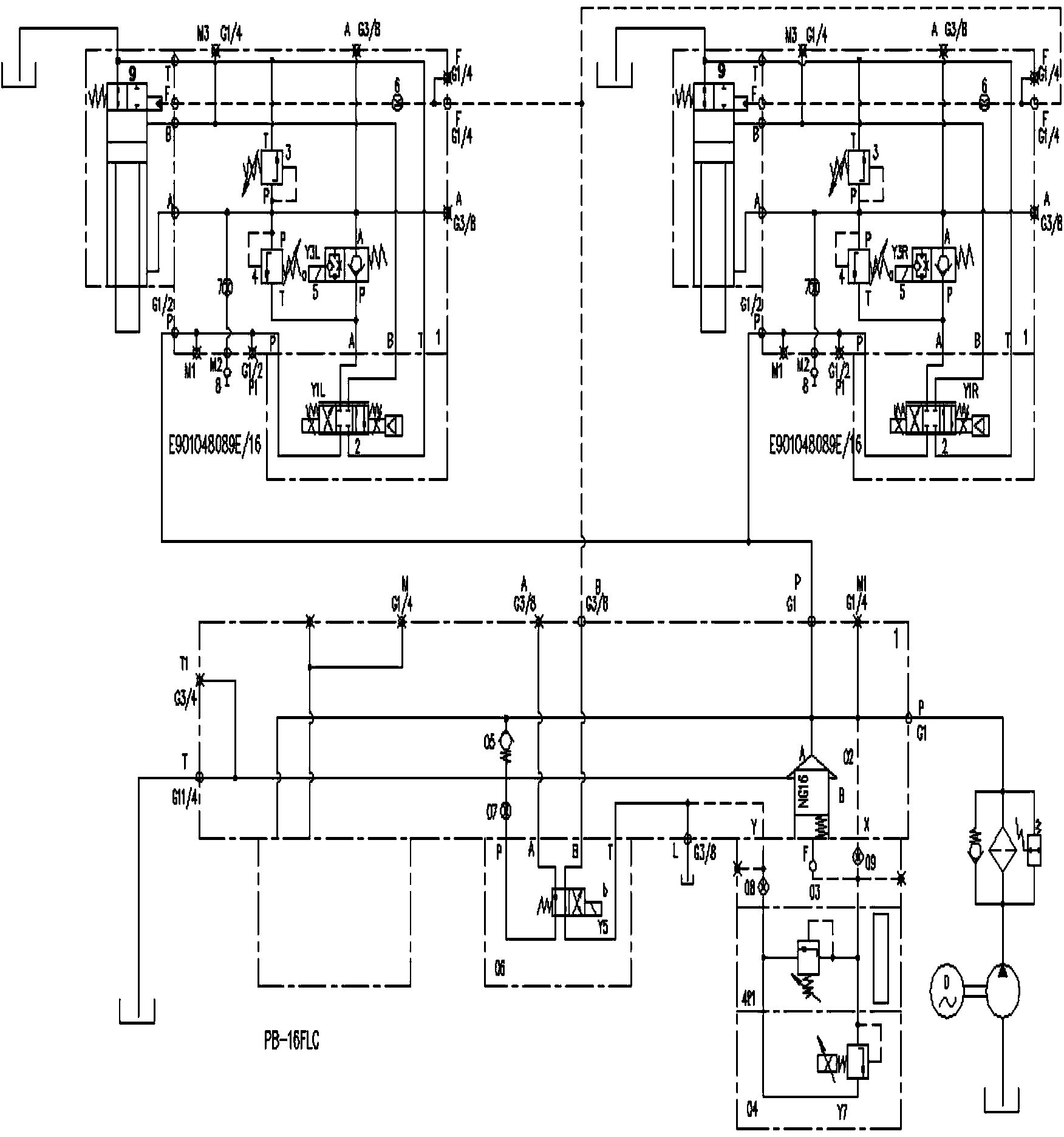

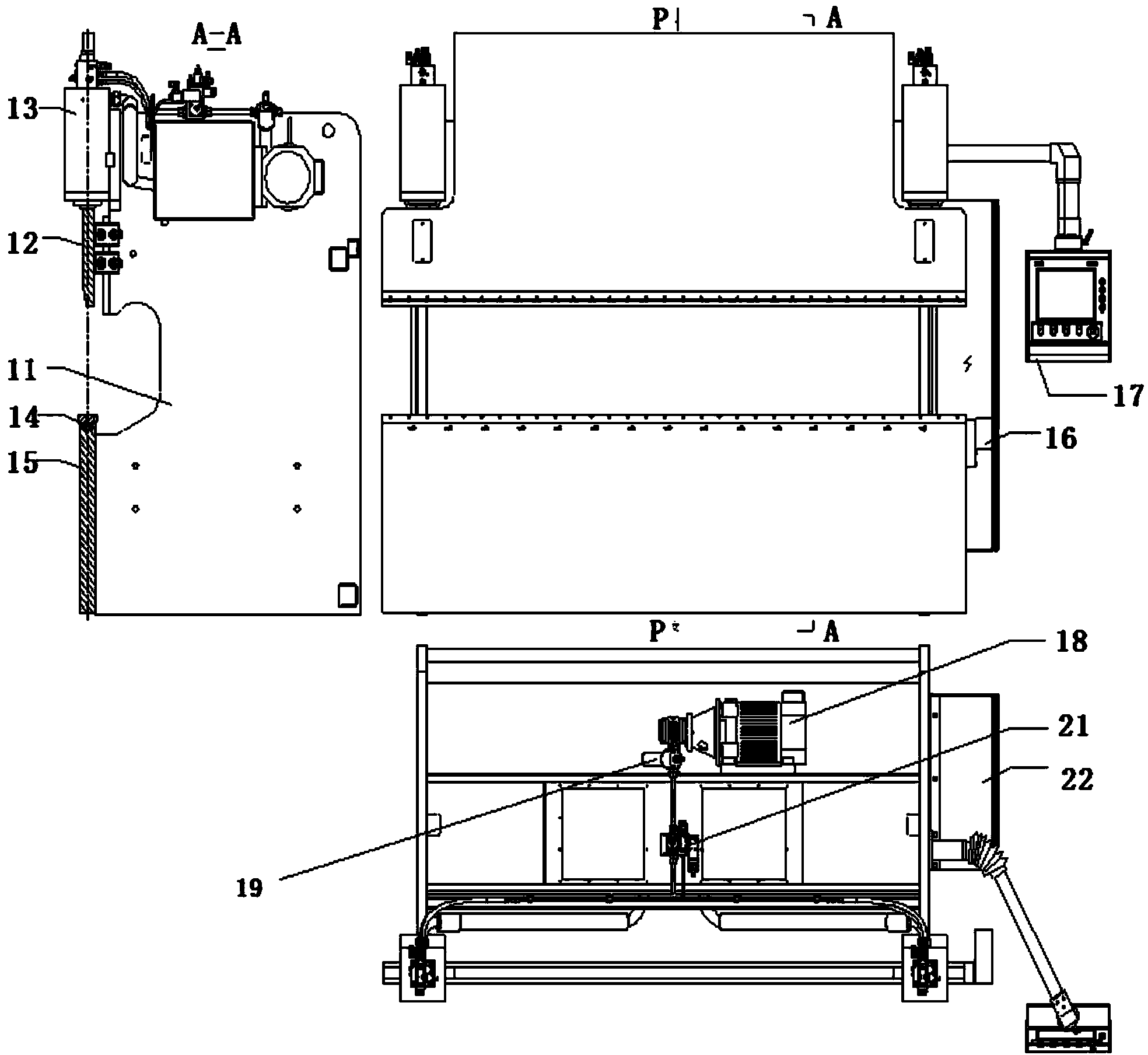

[0021] 1. The main structure and working principle of the fully closed-loop electro-hydraulic servo sheet metal bending machine

[0022] Such as Figure 1~2 As shown, the present invention includes: a fully closed-loop electro-hydraulic servo bending machine, including a frame 11, a main oil cylinder 13 located on both sides above the frame 11, a vertical plate 15 located at the lower part of the frame, and a vertical plate 15 located on the upper side A square mechanical deflection compensation workbench 14, a slide block 12 positioned above the vertical plate 15, and a numerical control system 17 located on the frame 11; also includes a hydraulic system 21, an electrical system 22 and a servo motor 18 connected to the numerical control system 17, And the oil pump 19 connected with the servo motor 18; the hydraulic system 21 is connected with the oil pump 19 and the oil cylinder 13; the cylinder piston rod of the oil cylinder 13 is connected with the slider 12;

[0023] When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com