Thin-hole sieve-plate-typed bubble column

A technology of fine-mesh sieve and bubble tower, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve the problems affecting the operation and processing efficiency of jet bubble towers, difficulties in manufacturing, installation and maintenance, and increased Large equipment volume and cost, etc., to achieve the effect of simple structure, low equipment investment and operation energy consumption, and small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

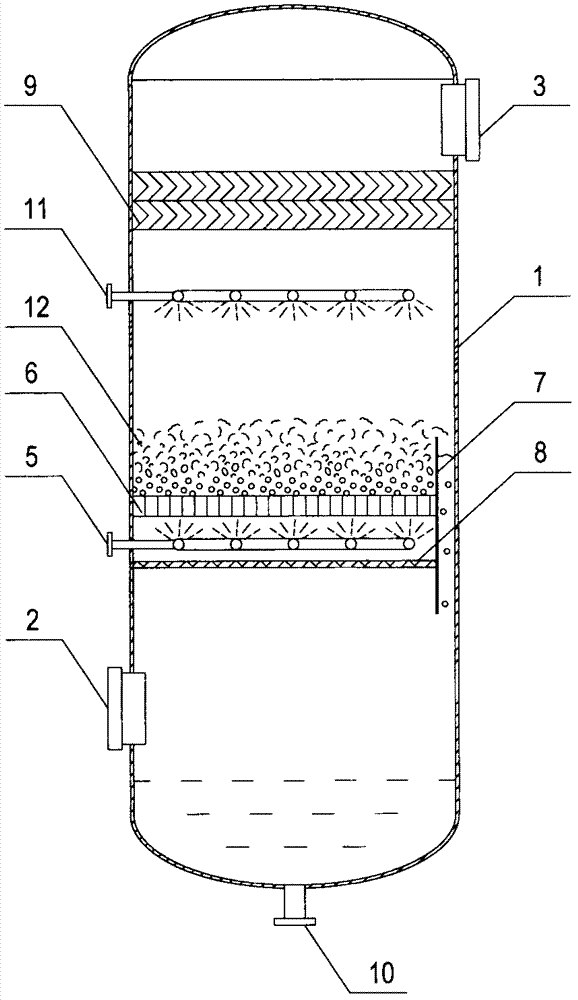

[0029] a kind of like figure 1 The fine-hole sieve plate bubble column shown includes a cylinder body 1, an air inlet 2, an air outlet 3, a liquid spray pipe 5, a sieve plate 6, an overflow plate 7, a liquid suction and ventilation net 8, and an auxiliary liquid inlet 11 and demister9. The gas inlet 2 is arranged at the lower part of the cylinder body and above the liquid level; the gas outlet 3 is arranged at the upper part of the cylinder body and above the bubbling layer of the tray.

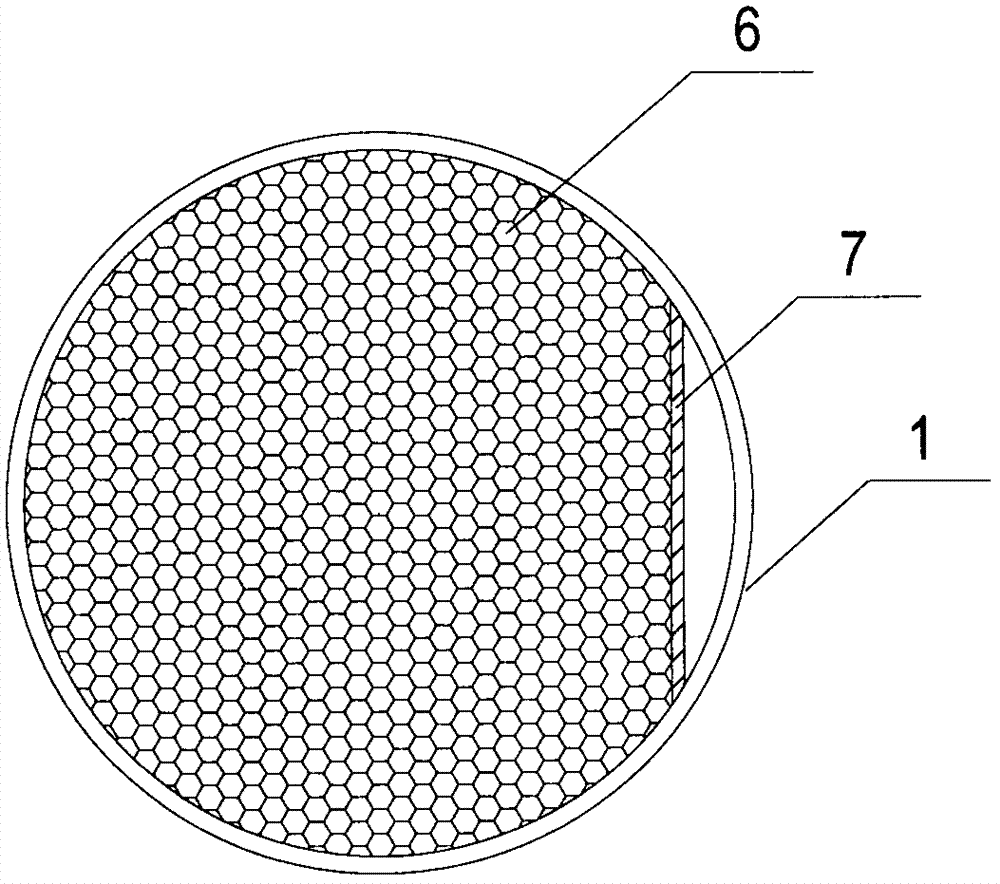

[0030] The bubble column tray in this embodiment is a fine-pore sieve plate 6, which is rolled and formed by metal sheets or ceramic fiber sheets, or stamped and formed by metal sheets, or injection molded. Its structural parameters are 3-30 mm in height, 0.5-5 mm in average aperture, and 0.3-0.9 in opening ratio. One side of the sieve plate 6 is provided with an overflow plate 7, and there are many V-shaped notches on the top of the overflow plate, which are 10-50mm higher than the sieve p...

Embodiment 2

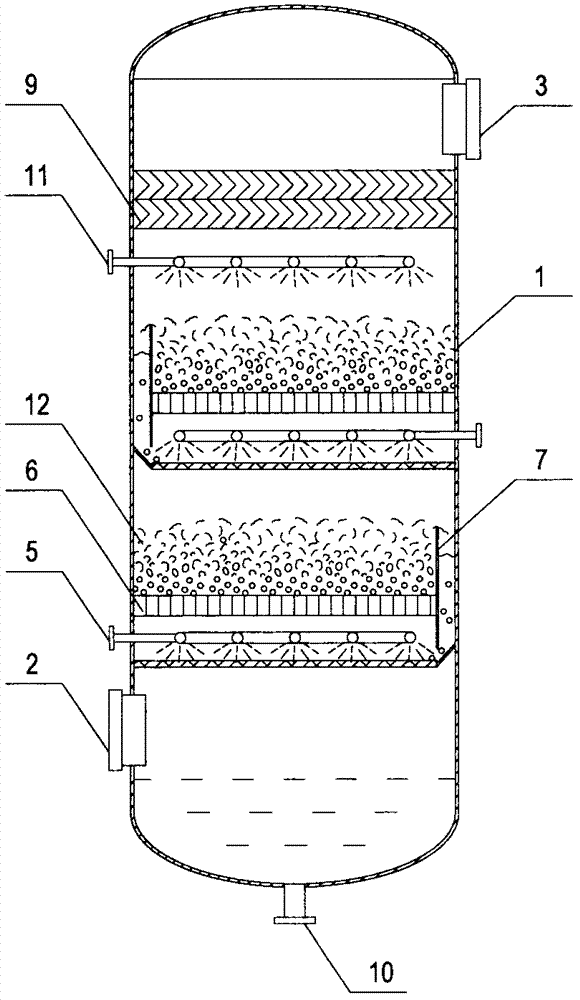

[0039] image 3 The fine-pore sieve plate bubble column shown is a bubble column with multiple layers of fine-pore sieve plates. It includes a cylinder body 1, an air inlet 2, an air outlet 3, a liquid spray pipe 5, a sieve plate 6, an overflow plate 7, a liquid suction and ventilation net 8, an auxiliary liquid inlet pipe 11 and a demister 9. The gas inlet 2 is arranged at the lower part of the cylinder body and above the liquid level; the gas outlet 3 is arranged at the upper part of the cylinder body and above the bubbling layer of the tray.

[0040] The bubble column tray in this embodiment is a microchannel fine-hole sieve plate 6, which is a screen with a certain height and spreads over the microporous channels. The preferred structural parameters are 10-20mm in height, 1-3mm in average pore size, 0.6 to 0.8. One side of the sieve plate 6 is provided with an overflow plate 7, and there are many V-shaped notches on the top of the overflow plate.

[0041] The bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com