Aircraft brake assembly

A braking assembly, aircraft technology, applied in aircraft braking arrangements, aircraft parts, brakes, etc., to achieve the effects of simple structural components, simplified raw materials, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

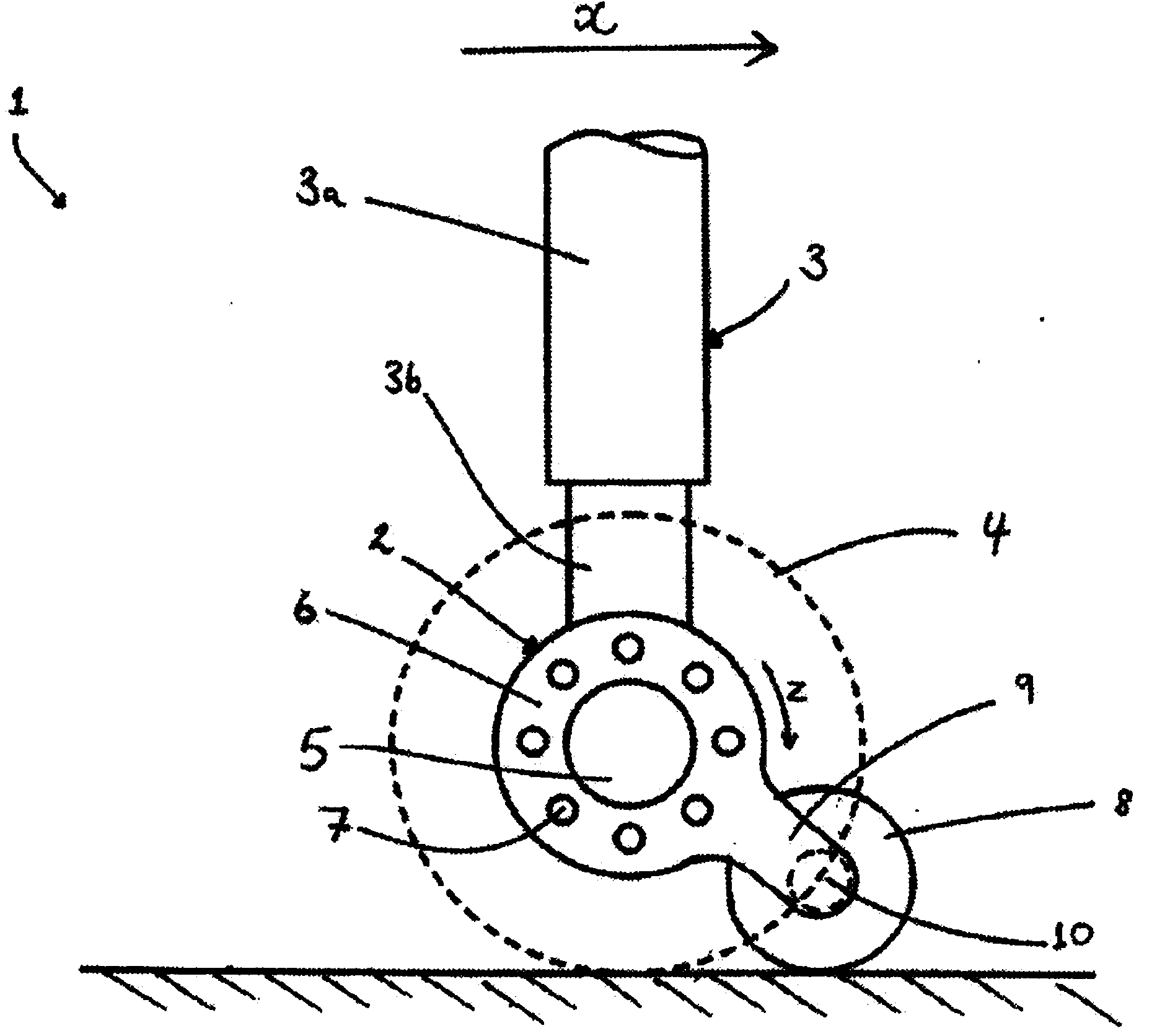

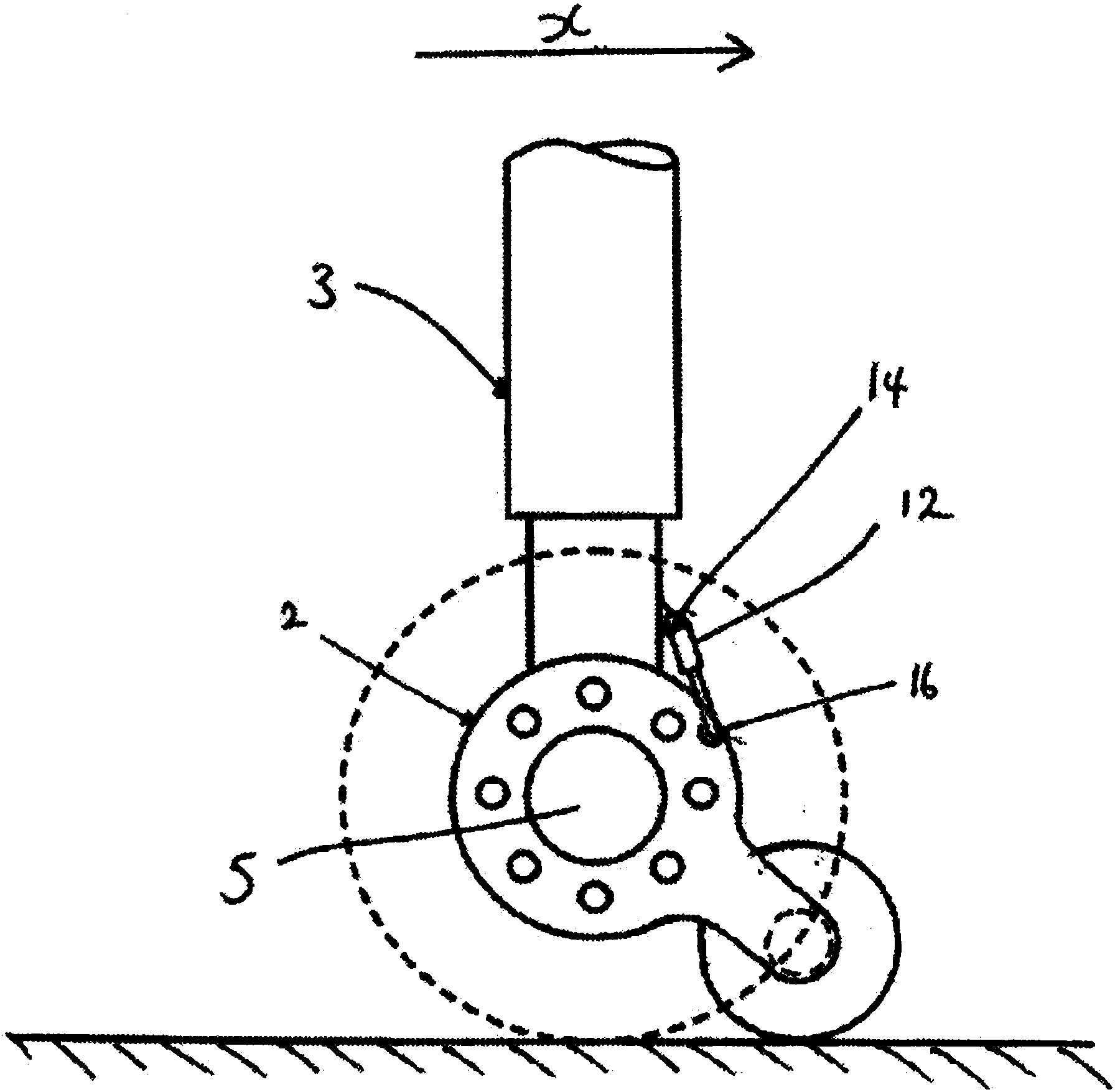

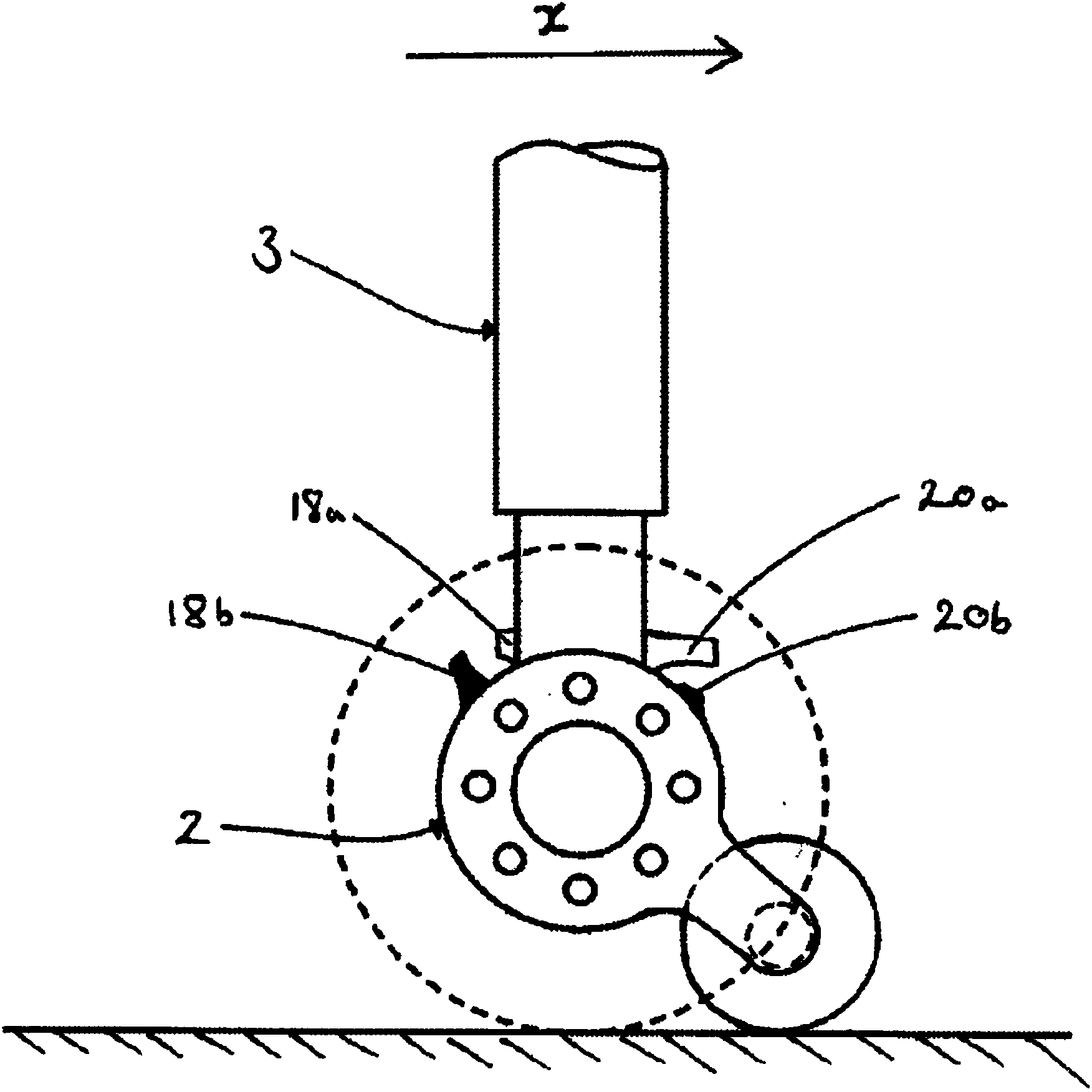

[0020] figure 1 An aircraft landing gear 1 comprising a braking assembly 2 according to an embodiment of the invention is shown, the aircraft landing gear 1 being on the ground. The aircraft landing gear 1 comprises a telescoping support leg 3 comprising an upper part 3a and a lower part 3b. Embodiments described herein include telescoping support legs. However, those skilled in the art will appreciate that the invention is equally applicable to aircraft landing gear comprising fixed undercarriage legs. In the embodiment shown, the undercarriage is a main undercarriage having a single pair of main wheels 4 at either end of the axle 5 , which may form part of the lower portion 3b of the telescoping support leg 3 . Those skilled in the art will appreciate that this design can be implemented on a main landing gear having a bogie beam with two or more pairs of tires with the mechanisms described herein incorporated into the wheels and one or more of the associated brakes. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com