Communicating tube used for high-capacity separating wiring

A separate, large-capacity technology, applied in the field of communication tubes, can solve the problems that affect the service life of cables, the form is not ideal, and the heat dissipation effect is not very good, so as to achieve the effect of improving service life, good heat dissipation effect and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

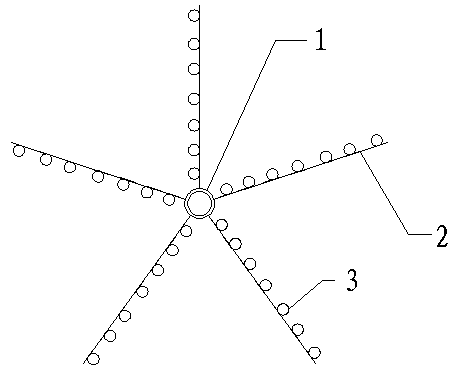

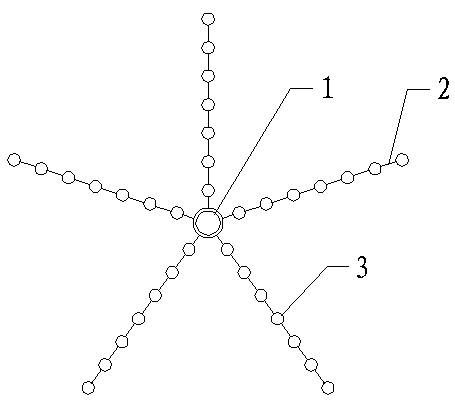

[0022] see Figure 1 to Figure 4 , a communication pipe for large-capacity separated wiring, including a pipe body, a threading device is arranged in the pipe body, the threading device has an intermediate pipe, and several sets of sub-threading structures are arranged on the intermediate pipe along the axial direction, the The sub-threading structure includes several support rods, the support rods are arranged in an annular array on the intermediate pipe, and several sub-wire tubes are arranged on each support rod, and the sub-wire tubes are arranged along the length direction of the support rods. A fastening device is provided at both ends of the intermediate pipe, and the fastening device includes a fixed ring sleeved on the end of the interm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com