System and method for predicting grinding particle size distribution of ball mill by fast Monte Carlo method

A Monte Carlo method and particle size distribution technology, applied in prediction, data processing applications, calculations, etc., can solve the problems of difficult-to-observe microscopic grinding process, randomness, lack of practicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

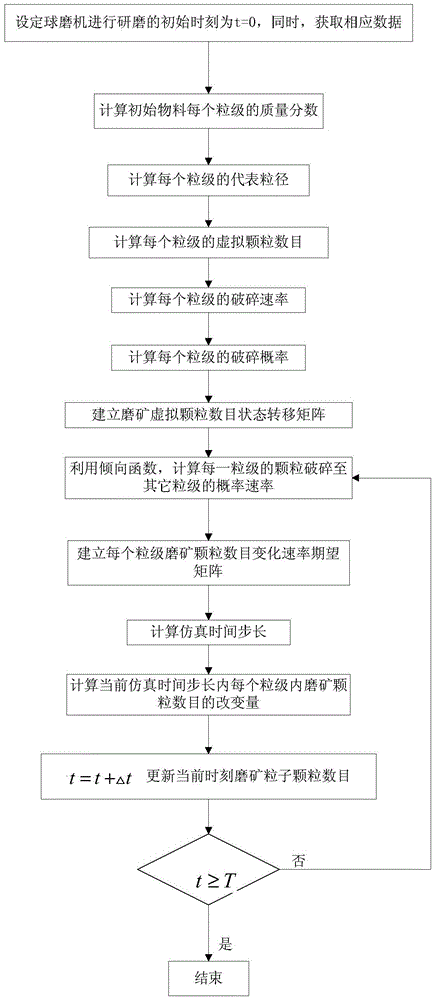

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

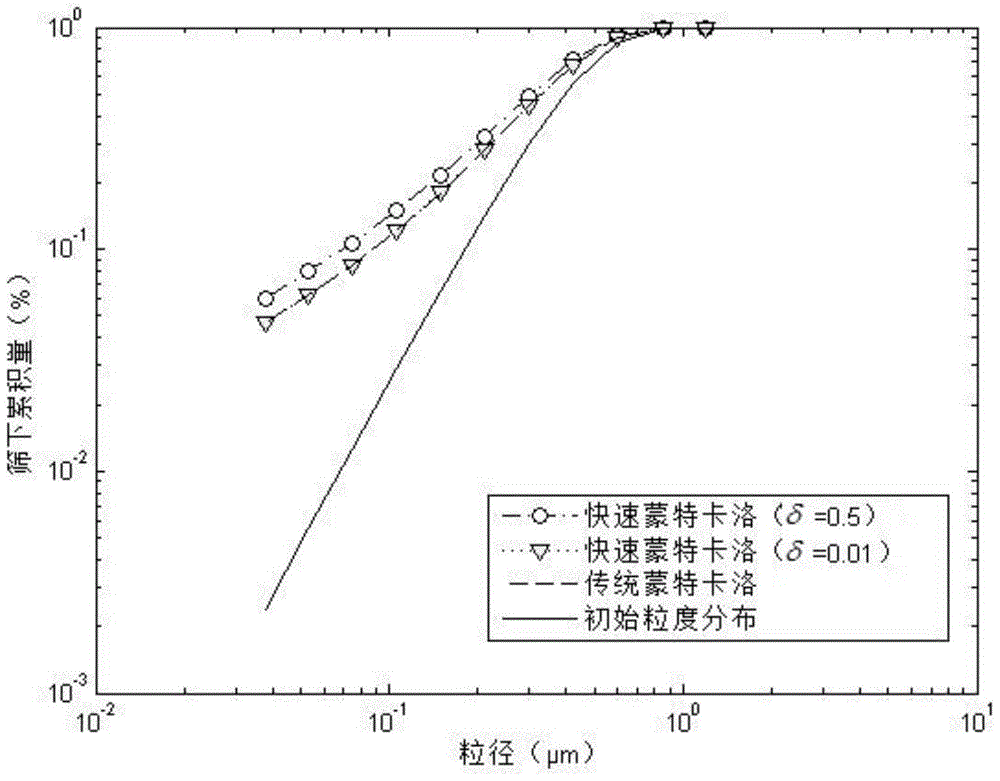

[0055] Monte Carlo simulation method is an effective stochastic statistical method, which is widely used in physics, chemistry and other fields. The biggest advantage of the Monte Carlo simulation method is that it does not need to transform the non-deterministic problem into a deterministic problem. It can directly start from the non-deterministic problem and solve the problem by simulating the actual process of the original problem. Therefore, the Monte Carlo simulation method With high precision. Due to the randomness of the ball mill grinding process itself, the Monte Carlo method is suitable for the particle size distribution prediction of the grinding process.

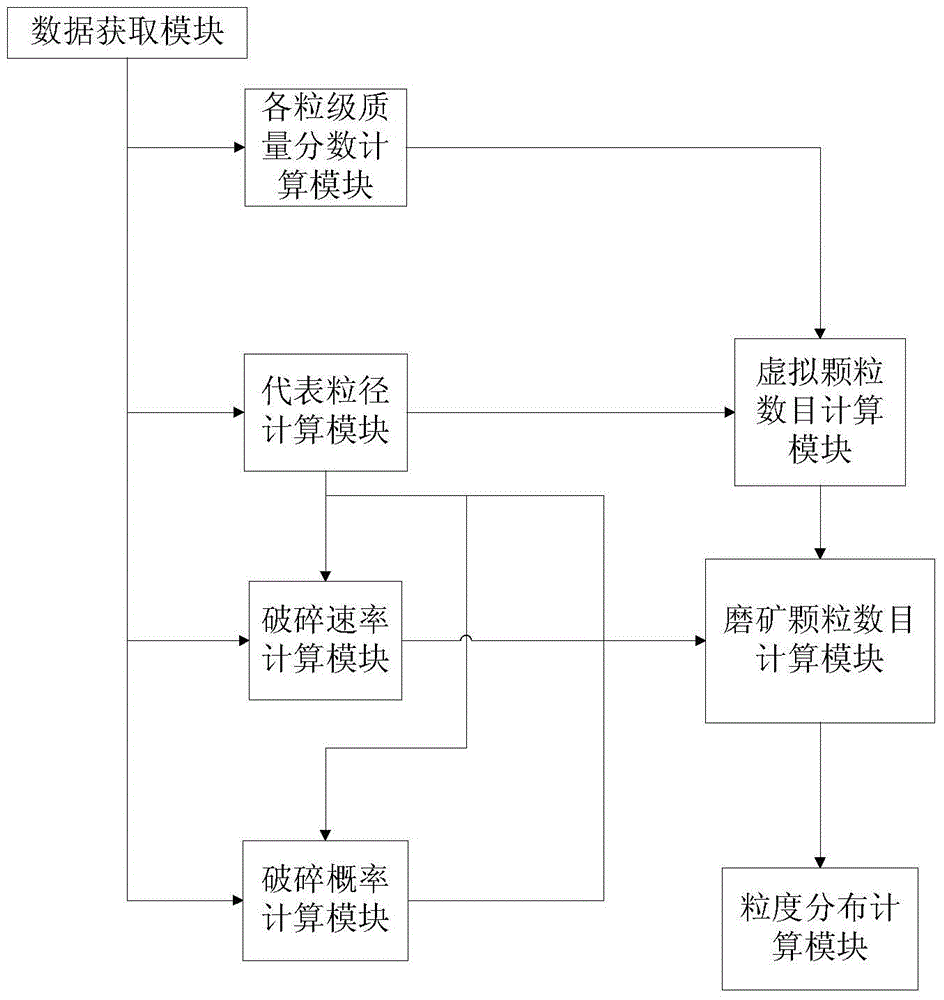

[0056] Such as figure 1 The system for predicting the ball mill grinding particle size distribution of the fast Monte Carlo method of the specific embodiment of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com