Lifting device type testing method and realization system thereof

A technology of lifting device and test method, which is applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problem of type test of incapable lifting device and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

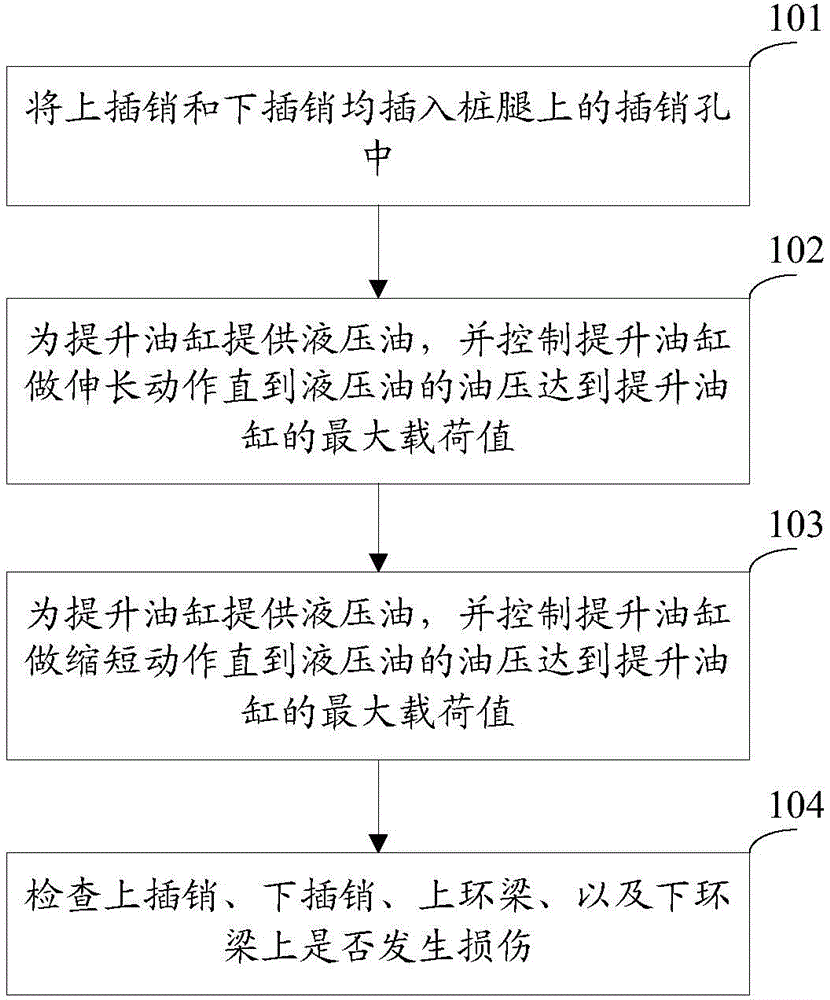

[0039] An embodiment of the present invention provides a type test method for a lifting device, which is suitable for a hydraulic bolt-type lifting device for an offshore platform. The lifting device includes an upper ring beam, an upper bolt arranged on the upper ring beam, a lower ring beam, and a The upper and lower bolts, and the upper and lower ends are respectively connected to the lifting cylinders of the upper ring beam and the lower ring beam. see figure 1 , the method includes:

[0040] Step 101: Insert both the upper pin and the lower pin into the pin holes on the legs.

[0041] In an implementation manner of this embodiment, step 101 may include:

[0042] Both the upper and lower pins are inserted into the pin holes on the pile legs by a pin oil cylinder.

[0043] In another implementation manner of this embodiment, step 101 may include:

[0044] Manually insert both the upper pin and the lower pin into the pin holes on the legs.

[0045] Step 102 : providing ...

Embodiment 2

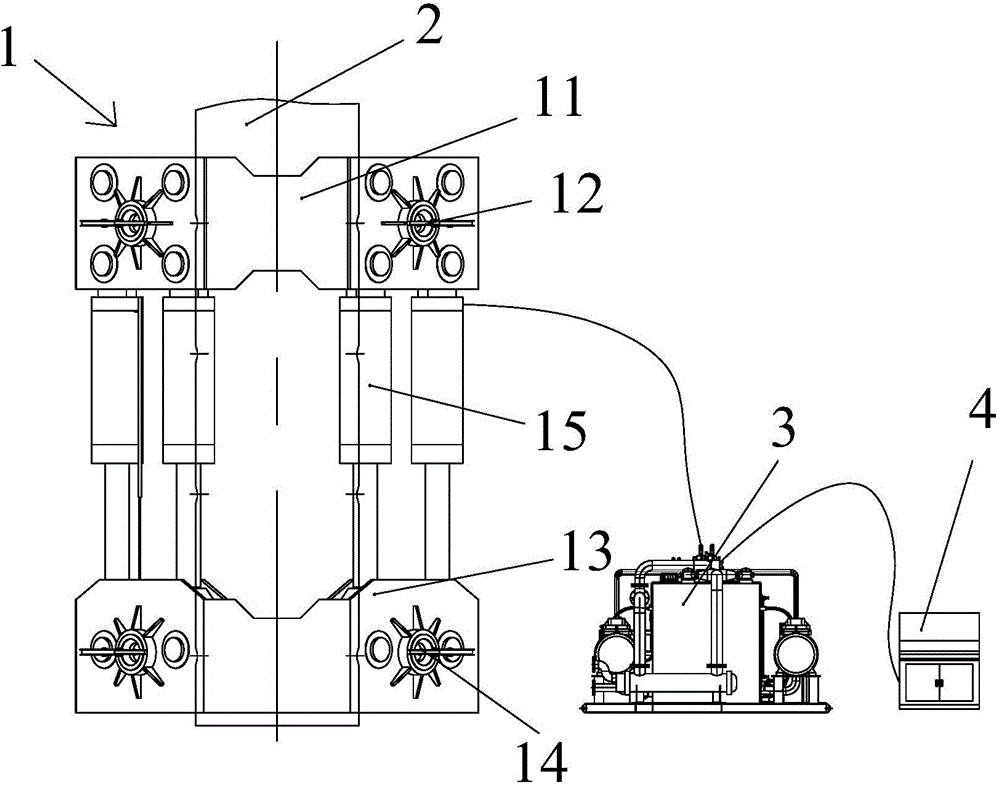

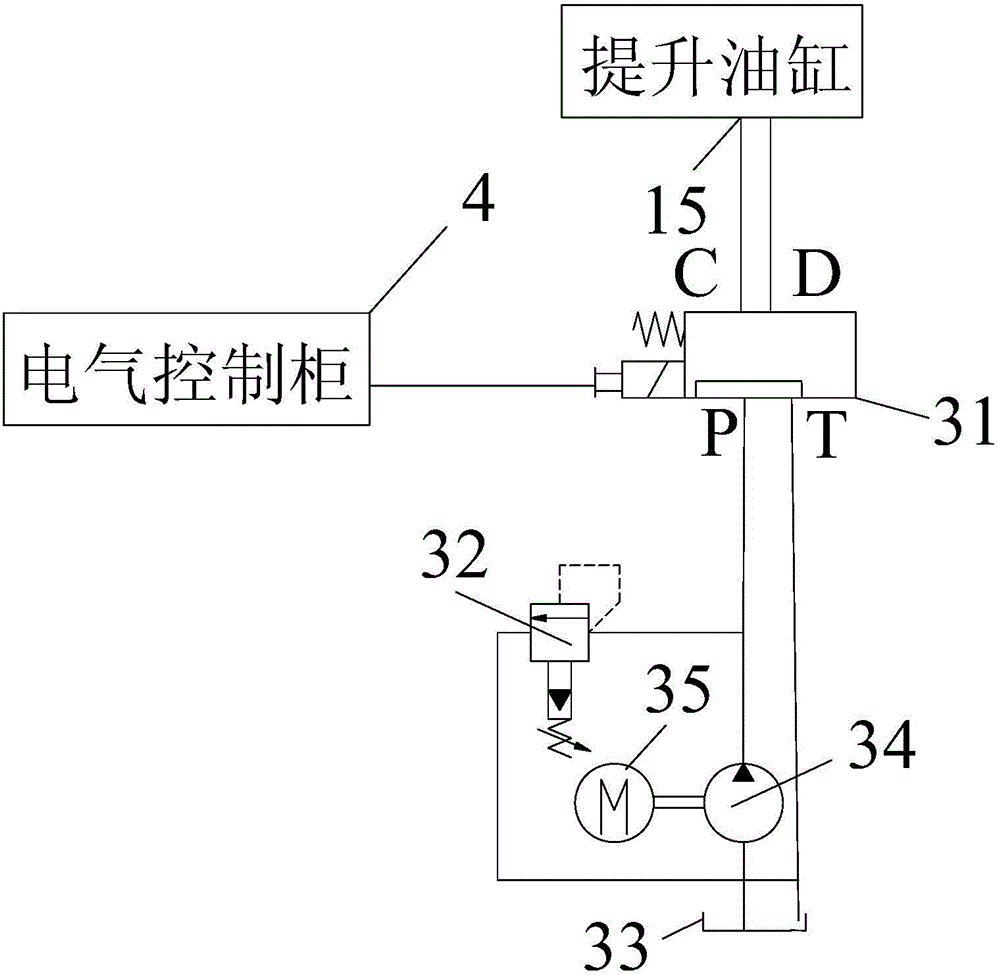

[0069] The embodiment of the present invention provides a system for realizing the type test method of the lifting device as provided in the first embodiment, see figure 2 , the system includes a lifting device 1 , legs 2 , a hydraulic pump station 3 , and an electrical control cabinet 4 .

[0070] In this embodiment, the lifting device 1 includes an upper ring beam 11, an upper bolt 12 arranged on the upper ring beam 11, a lower ring beam 13, a lower bolt 14 arranged on the lower ring beam 13, and upper and lower ends respectively connected to the upper Lift cylinder 15 of ring beam 11 and lower ring beam 13. The upper bolt 12 and the lower bolt 14 are respectively inserted into the bolt holes of the legs 2 .

[0071] The hydraulic pump station 3 is in communication with the lifting cylinder 15 , and the electrical control cabinet 4 is electrically connected with the hydraulic pump station 3 .

[0072] Optionally, the pitch of the pin holes of the legs 2 is greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com