Installation and adjustment method of vacuum ultraviolet plane grating dispersive spectrometer

A technology of vacuum ultraviolet light and plane grating is applied in the field of spectroscopy, which can solve the problems of high installation and adjustment cost, difficulty in precise adjustment, and reduced installation and adjustment accuracy, and achieves the effects of low cost, high precision, and less labor and time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The implementation of the method of the present invention will be further described in detail below in conjunction with the accompanying drawings.

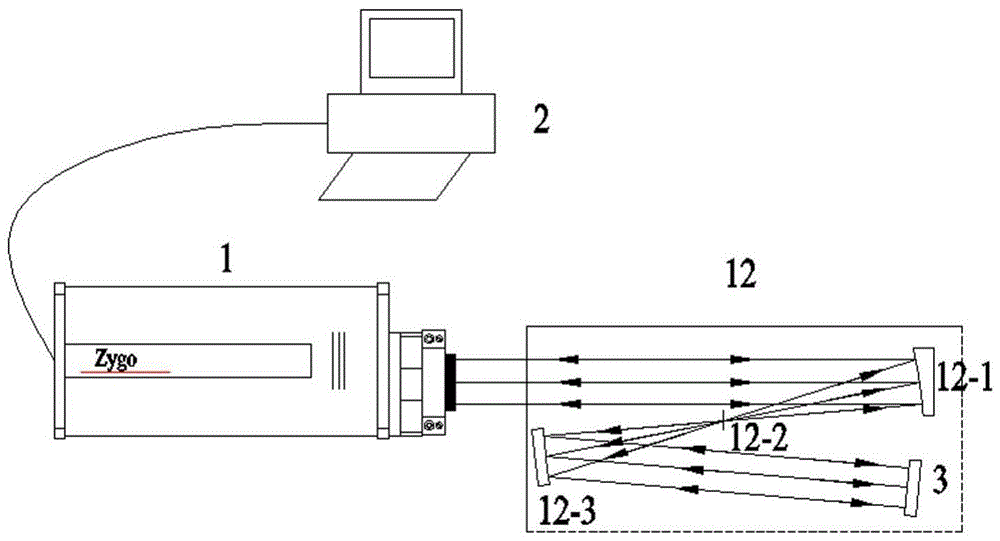

[0017] Such as figure 1 As shown, the vacuum ultraviolet grating 12 - 4 is replaced by a plane mirror 3 in the spectrometer 12 , and the spectrometer 12 is irradiated by the collimated light emitted by the Zygo interferometer 1 . First adjust the telescope 12-1 in the spectrometer 12, the slit 12-2 and the collimating mirror 12-3, so that the outgoing light of the collimating mirror 12-3 is a collimated light; then adjust the plane mirror 3 to follow the collimated light along the original optical path Return to Zygo Interferometer 1. The computer control processing system 2 is connected with the Zygo interferometer 1 to observe the wave aberration and fine-tune the front-end optical components, and obtain the optimal wave aberration image of the system through the computer control processing system 2 to complete the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com