Hard rock tunnel non-blasting digging blocking method and construction method

A tunnel excavation, non-blasting technology, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as low work efficiency, high wear and tear of washing hair, and difficulty in meeting engineering requirements, so as to improve utilization rate and eliminate construction vibration , to avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

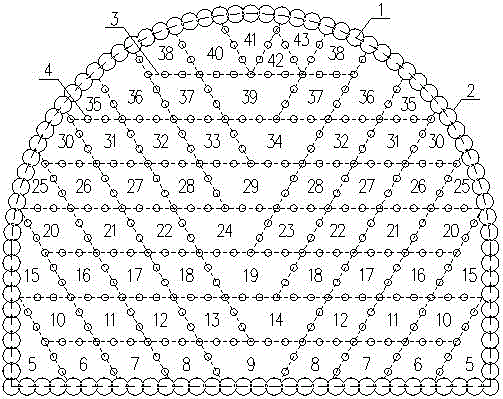

[0023] Such as figure 1 Shown, a kind of hard rock tunnel non-blasting excavation block method is characterized in that, comprises the following steps:

[0024] 1) Boreholes are drilled along the tunnel excavation contour line 1 and using corresponding borehole insertion angles. Adjacent boreholes overlap and occlude each other, and finally form peripheral holes 2 where adjacent boreholes cut each other, so that the tunnel face It is completely separated from the surrounding rock of the tunnel, so as to form a borehole wall-like excavation free surface around the tunnel face. In the embodiment of the present invention, the diameter of the peripheral hole 2 is 20cm, and the distance between the drill holes is 18cm. The occlusal overlap thickness is 2cm;

[0025] 2) In the face of the palm, several rows of 4 rows of splitting holes arranged in parallel or intersecting each other are drilled, each row of 4 rows of splitting holes forms a splitting surface 3, and several splittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com