Artificial foaming-oil huff and puff oil production method for heavy oil reservoir

A heavy oil reservoir and foam oil technology, applied in the field of oil production, can solve the problems of improving the rheological properties of crude oil, lack of nitrogen, and inability to obtain it, so as to increase overall fluidity and elastic energy, reduce viscosity, and improve oil reservoir recovery. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

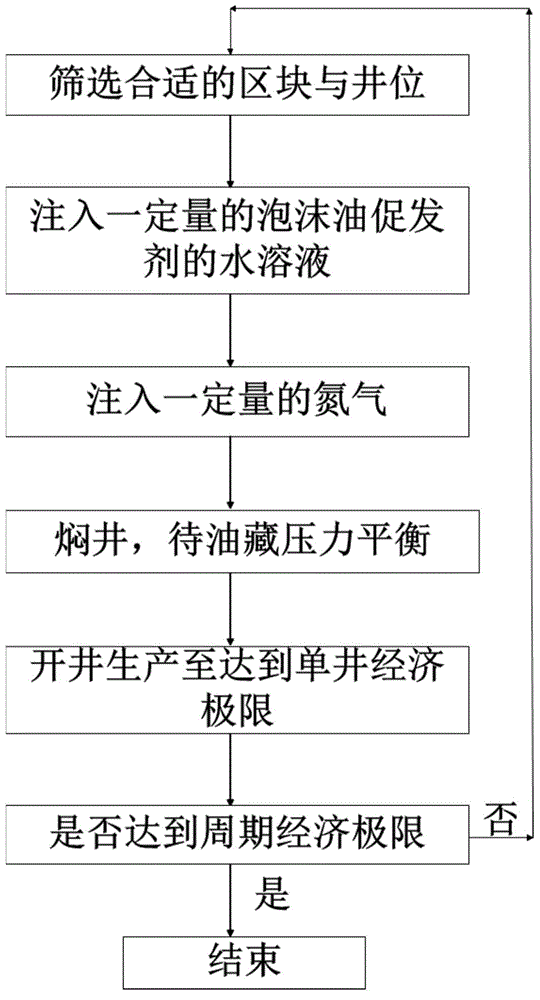

[0058] This embodiment provides a method for artificial foam oil huff and puff recovery in heavy oil reservoirs, the process flow is as follows figure 1 As shown, the selected heavy oil reservoir is a domestic heavy oil reservoir with a depth of 2155m. As of the end of March 2013, the proven oil geological reserves were 98.67 million tons, and the production rate was 59.63 million tons, with a production rate of 60.4 %. There are 457 development wells in the central and western areas of the oilfield, 331 oil wells have been opened, with a daily oil production of 1358 tons, an average daily output of 4.0 tons per well, 96 water wells opened, daily water injection of 3067 cubic meters, and a single well of daily water injection of 32 cubic meters. 66%, the oil recovery rate is 0.81%, and the recovery degree is 3.82%. The overall structural shape of the reservoir is a large nose-shaped uplift that gradually dips from east to west, and the distribution of the structure has the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com