Method for extracting lithium from salt lake brine by using adsorption method

A technology of salt lake brine and adsorption method, applied in the field of lithium extraction, can solve the problems of long operation cycle and low utilization efficiency of adsorbents, and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

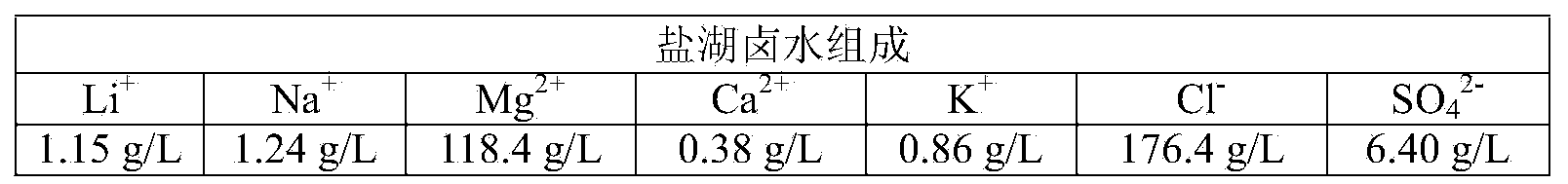

Embodiment 1

[0034] 100g FeSO 4 The ion sieve adsorbent was added to 50L of salt lake brine, heated and stirred, the temperature of the solution was controlled to be 40°C, and stirred for 60min. + into the adsorbent, at this time Li in the solution + The concentration of FeSO decreased to 1.07g / L, FeSO 4 The adsorption of Li on the ion sieve adsorbent is about 40mg / g, and then it is filtered and concentrated by a ceramic membrane. The average pore size of the ceramic membrane is 5, 20, 50, 200, and 500 nm, the filtration pressure is 0.2 MPa, and the flow rate on the membrane surface is 3 m / s. , the filtration temperature is 50 °C, the recoil interval is 40 min, and the recoil time is 10 s; the clear liquid can enter the magnesium extraction process to recover magnesium, and the ceramic membrane filtration concentrate is subjected to plate and frame pressure filtration to remove most of the impurities and water in the concentrate. The adsorption filter cake that has adsorbed lithium, the ...

Embodiment 2

[0039] 100g FeSO 4 The ion sieve adsorbent was added to 50L of salt lake brine, heated and stirred, the temperature of the solution was controlled to 50°C, and stirred for 50min. + into the adsorbent, at this time Li in the solution + The concentration of FeSO decreased to 1.02g / L, FeSO 4 The adsorption of Li by the ion sieve adsorbent is about 40mg / g, and then it is filtered and concentrated by a ceramic membrane. The average pore size of the ceramic membrane is 200nm, the filtration pressure is 0.4MPa, and the membrane surface flow rate is 0.5m / s, 1m / s, 2m respectively. / s, 3m / s, 4m / s, 5m / s, the filtration temperature is 60°C, the recoil interval is 40min, and the recoil time is 30s; the supernatant can enter the magnesium extraction process to recover magnesium, and the ceramic membrane filtration concentrate is pressed by the plate and frame Filtration to remove most of the impurities and water in the concentrated solution to obtain an adsorption filter cake that has ads...

Embodiment 3

[0044] 100g FeSO 4 The ion sieve adsorbent was added to 50L of salt lake brine, heated and stirred, the temperature of the solution was controlled to 50°C, and stirred for 50min. + into the adsorbent, at this time Li in the solution + The concentration of FeSO decreased to 1.02g / L, FeSO 4 The adsorption of Li by the ion sieve adsorbent is about 40mg / g, and then it is filtered and concentrated by a ceramic membrane. The average pore size of the ceramic membrane is 200nm, the filtration pressure is 0.4MPa, the dead-end filtration mode is adopted, the filtration temperature is 60℃, and the backwash interval is 40min. , the recoil time is 30s, and the concentration ratio is about 30 times; the clear liquid can enter the magnesium extraction process to recover magnesium, and the ceramic membrane filtration concentrated liquid is subjected to plate and frame pressure filtration to remove most of the impurities and water in the concentrated liquid. Adsorption filter cake, the filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com