Environment-friendly roasted coal and preparation method thereof

An environmentally friendly, white coal technology, applied in the energy field, can solve the problems of high sulfur content, not in line with environmental protection, etc., and achieve the effects of reducing sulfur dioxide, fewer steps, and easy combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

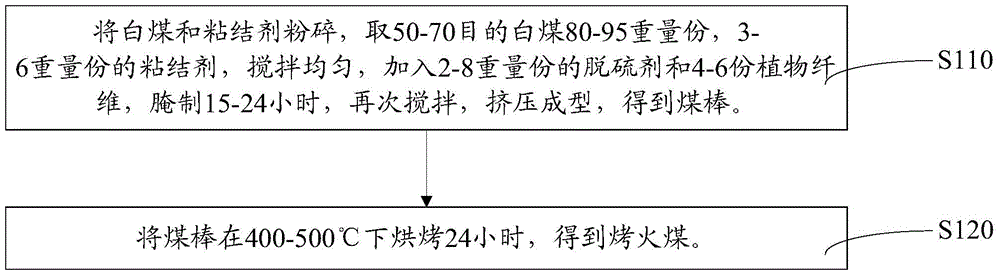

[0028] The preparation method of the above-mentioned baked coal comprises the following steps:

[0029] Step S110, pulverize white coal and binder, take 80-95 parts by weight of white coal of 50-70 mesh, 3-6 parts by weight of binder, stir evenly, add 2-8 parts by weight of desulfurizer and 4- 6 parts of plant fibers were marinated for 15-24 hours, stirred again, and extruded to obtain coal sticks.

[0030] Among them, in the process of pulverizing the white coal and the binder, if the pulverized particles are too large, the bonding strength of the roasted coal will be affected; Difficult to shape, affecting the strength of the coal fired. Therefore, the mesh number of the control particles is 50-70 mesh.

[0031] The purpose of pickling the white coal, binder and desulfurizer is to allow the white coal to fully absorb the binder and desulfurizer. In this embodiment, the above components are stirred and then piled up for pickling.

[0032] After the white coal, binder, des...

Embodiment 1

[0036] Pulverize white coal and binder, get 80 kilograms of 50-70 mesh white coal, 3 kilograms of binder, 2 kilograms of desulfurizer, 4 kilograms of plant fiber;

[0037] Wherein, in the binder, by weight, there are 280 parts of kaolin, 85 parts of humic acid, 295 parts of bentonite, and 80 parts of cornstarch;

[0038] In the desulfurizer, by weight, 20 parts of hexamethylenetetramine, 45 parts of sodium nitrate, 45 parts of potassium nitrate, 20 parts of potassium permanganate, 20 parts of industrial salt, 45 parts of industrial essence, 8 parts of quicklime, hydrogen Sodium oxide 8 parts;

[0039] marinating the above components for 15-24 hours, stirring again, and extruding to obtain coal sticks;

[0040] The coal sticks are baked at 400-500° C. for 24 hours to obtain baked coal.

Embodiment 2

[0042] Pulverize white coal and binder, get 95 kilograms of 50-70 mesh white coal, 6 kilograms of binder, 8 kilograms of desulfurizer, 6 kilograms of plant fiber;

[0043] Wherein, in the binder, by weight, there are 320 parts of kaolin, 105 parts of humic acid, 310 parts of bentonite, and 100 parts of cornstarch;

[0044] In the desulfurizer, by weight, 30 parts of hexamethylenetetramine, 55 parts of sodium nitrate, 55 parts of potassium nitrate, 30 parts of potassium permanganate, 30 parts of industrial salt, 55 parts of industrial essence, 12 parts of quicklime, hydrogen 12 parts of sodium oxide;

[0045] marinating the above components for 15-24 hours, stirring again, and extruding to obtain coal sticks;

[0046] The coal sticks are baked at 400-500° C. for 24 hours to obtain baked coal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com