Preparation method of luminous decorative plate

A decorative board and luminous powder technology, applied in the field of surface decoration materials, to achieve the effect of long luminous afterglow, strong luminous performance, and natural and realistic texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

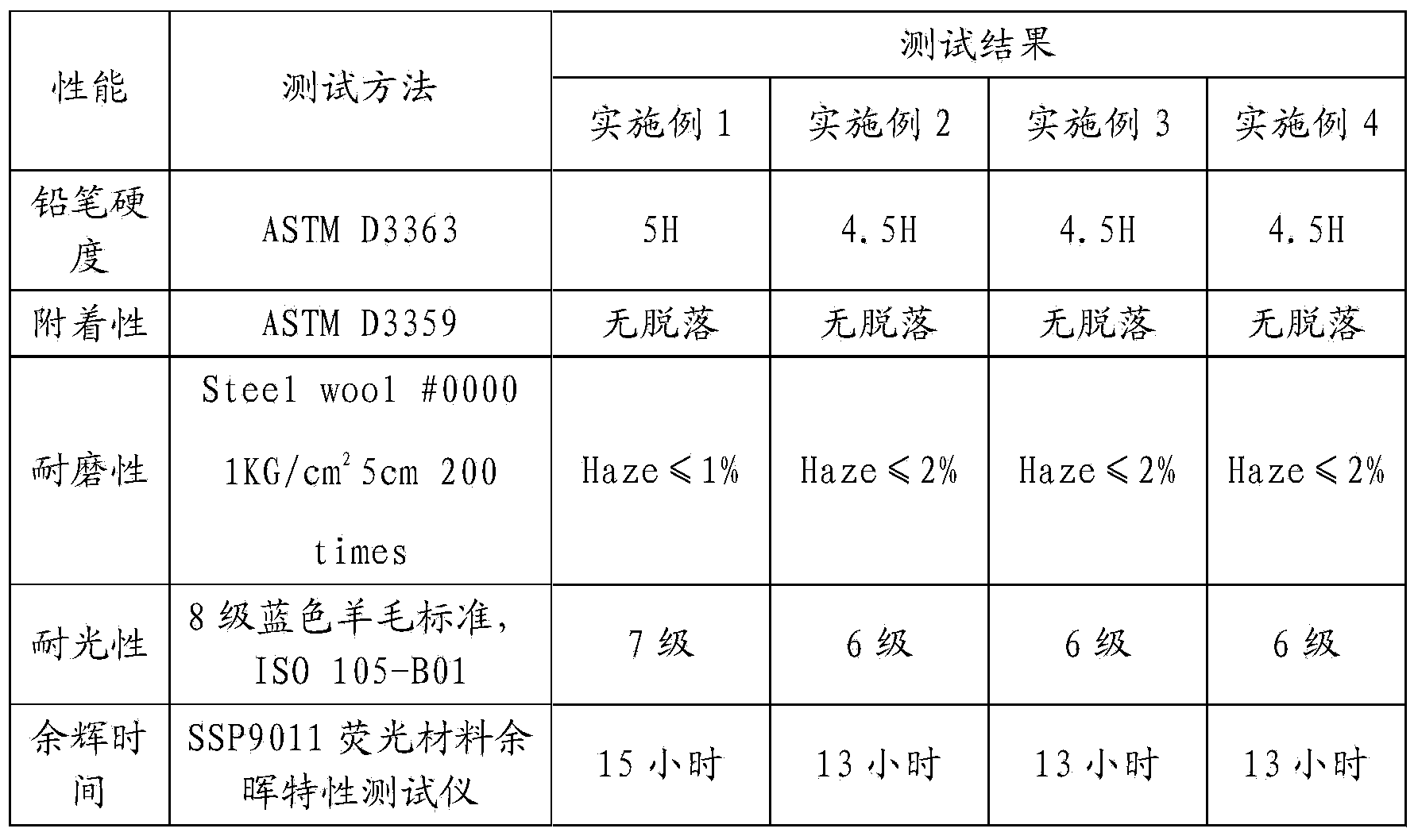

Examples

Embodiment 1

[0025] A preparation method of a luminous decorative board, carried out according to the following steps:

[0026] 1) Material preparation: provide a kind of water-based luminous ink, which is prepared from the following raw materials by weight percentage:

[0027] Material A: water-based acrylic resin 15%; luminous powder 15%; dispersant 1.5%; defoamer 0.2%; tap water 10%;

[0028] Material B: 10% casein solution; 0.4% defoamer; 1% anti-settling agent; 5% ethanol; 2% propylene glycol; 38% tap water; 0.4% wetting and leveling agent;

[0029] Material C: thickener 0.8%; pH regulator 0.5%;

[0030] The preparation method of the water-based luminous ink is as follows: 1) feed A material at high speed (2000 rpm) and disperse for 1.5-2 hours; 2) add B material and mix and disperse for 30 minutes; 3) adjust the viscosity with the thickener in C material , adjust the pH value with ethylamine;

[0031] 2) printing: using the water-based luminous ink described in step 1 to carry out...

Embodiment 2

[0042] The characteristics of this embodiment are:

[0043] In step 1), the water-based luminous ink is prepared from the following raw materials by weight percentage:

[0044] Material A: water-based acrylic resin 5%; luminous powder 9.5%; dispersant 0.5%; defoamer 0.2%; water 20%;

[0045] Material B: 15% casein solution; 0.3% defoamer; 0.5% anti-settling agent; 5% ethanol; 2% propylene glycol; 40% water; 1% wetting and leveling agent;

[0046] Material C: thickener 0.5%; pH regulator (ethanolamine) 0.5%;

[0047] In step 2), the printing process parameters are as follows: the water-based luminous ink is diluted with a diluent to a printing viscosity of 18s / tu 4# cup (25°C); the pressure of the rubber roller is 0.3MPa; the angle of the scraper is 45°; the length of the oven 5 meters, the oven temperature is 130°C; the printing speed is 120m / min.

[0048] In step 3), the oven temperature of the dipping machine is set at 165°C; the amount of gluing is controlled at 150%, th...

Embodiment 3

[0052] The characteristics of this embodiment are: in step 1), the water-based luminous ink is prepared from the following raw materials by weight percentage:

[0053] Material A: water-based acrylic resin 20%; luminous powder 10%; dispersant 2%; defoamer 0.3%; water 10%;

[0054] Material B: 20% casein solution; 0.3% defoamer; 2% anti-settling agent; 10% ethanol; 5% propylene glycol; 14.9% water; 2% wetting and leveling agent;

[0055] C material: thickener 2%; pH regulator (ethanolamine) 1%;

[0056] Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com