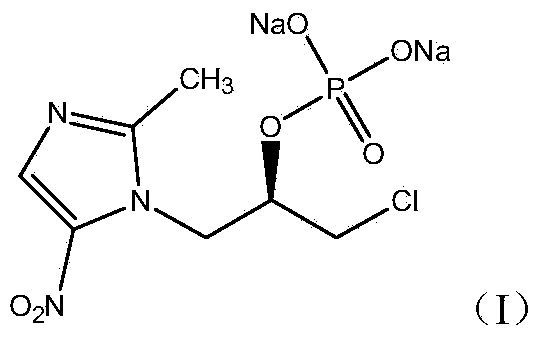

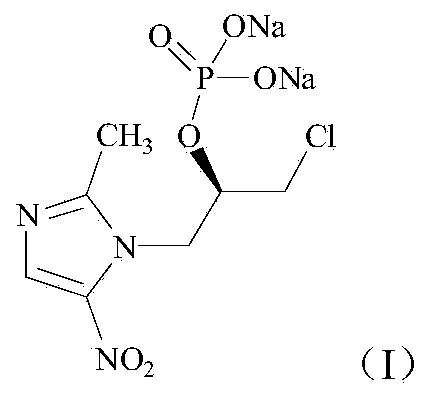

Industrial production method of s-(-)-ornidazole disodium phosphate

A technology of levo-ornidazole and crude product of levo-ornidazole, applied in the field of disodium phosphate of levo-ornidazole, can solve problems affecting product quality, high boiling point, residue, etc., to achieve environmental protection, improve product quality, The effect of lowering the limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

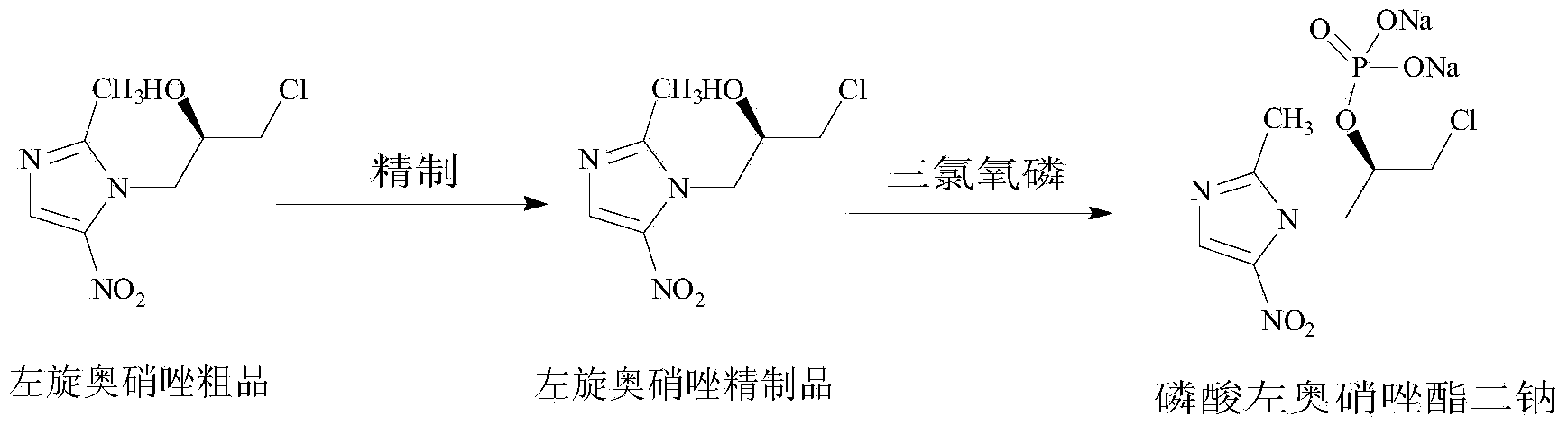

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 L-ornidazole

[0029] Add 800ml of water to 100g of levorotatory crude product, slowly add dilute hydrochloric acid dropwise to pH 3.0, filter to remove insoluble matter, add saturated sodium bicarbonate solution to the obtained filtrate, adjust pH to 7.5, add about 100mg of saturated sodium chloride solution, A large amount of precipitates precipitated, stirred for about 1-3 hours, filtered, washed with an appropriate amount of water, and dried to obtain 85 g of L-ornidazole with a HPLC purity of 99.8%.

Embodiment 2

[0030] The preparation of embodiment 2 L-ornidazole

[0031] Add 100 g of the crude product of L-ornidazole, add 500 ml of toluene, heat up to 80-100° C. to dissolve and clarify, filter, and the filtrate is slowly cooled to room temperature, crystals are precipitated, filtered, and dried to obtain 80 g of L-ornidazole with an HPLC purity of 99.0%.

Embodiment 3

[0032] The preparation of embodiment 3 L-ornidazole phosphate disodium

[0033] Add 100 g of L-ornidazole, add 600 ml of ethyl acetate, slowly dropwise add 120 ml of phosphorus oxychloride, stir and react at 30°C, after the reaction is completed, concentrate under reduced pressure to remove the solvent to obtain a slurry, add 100 ml of water to the obtained slurry, Adjust the pH to 4 with sodium carbonate, concentrate under reduced pressure, add 200 ml of ethanol to the concentrate, cool to room temperature, filter to remove insoluble inorganic salts, adjust the pH of the obtained filtrate to 7.5 with 20% sodium hydroxide solution, precipitate a white solid, filter, and dry at 30 121 g of L-ornidazole phosphate was obtained by vacuum drying at ℃, the content was 99.5%, and the total inorganic salt content was about 0.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com