Production method of diammonium hydrogen citrate

A technology of diammonium hydrogen citrate and its production method, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve complex production process of diammonium hydrogen citrate, increase production cost, Problems such as narrow scope of application, to achieve the effect of simple and scientific production process, good product quality and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

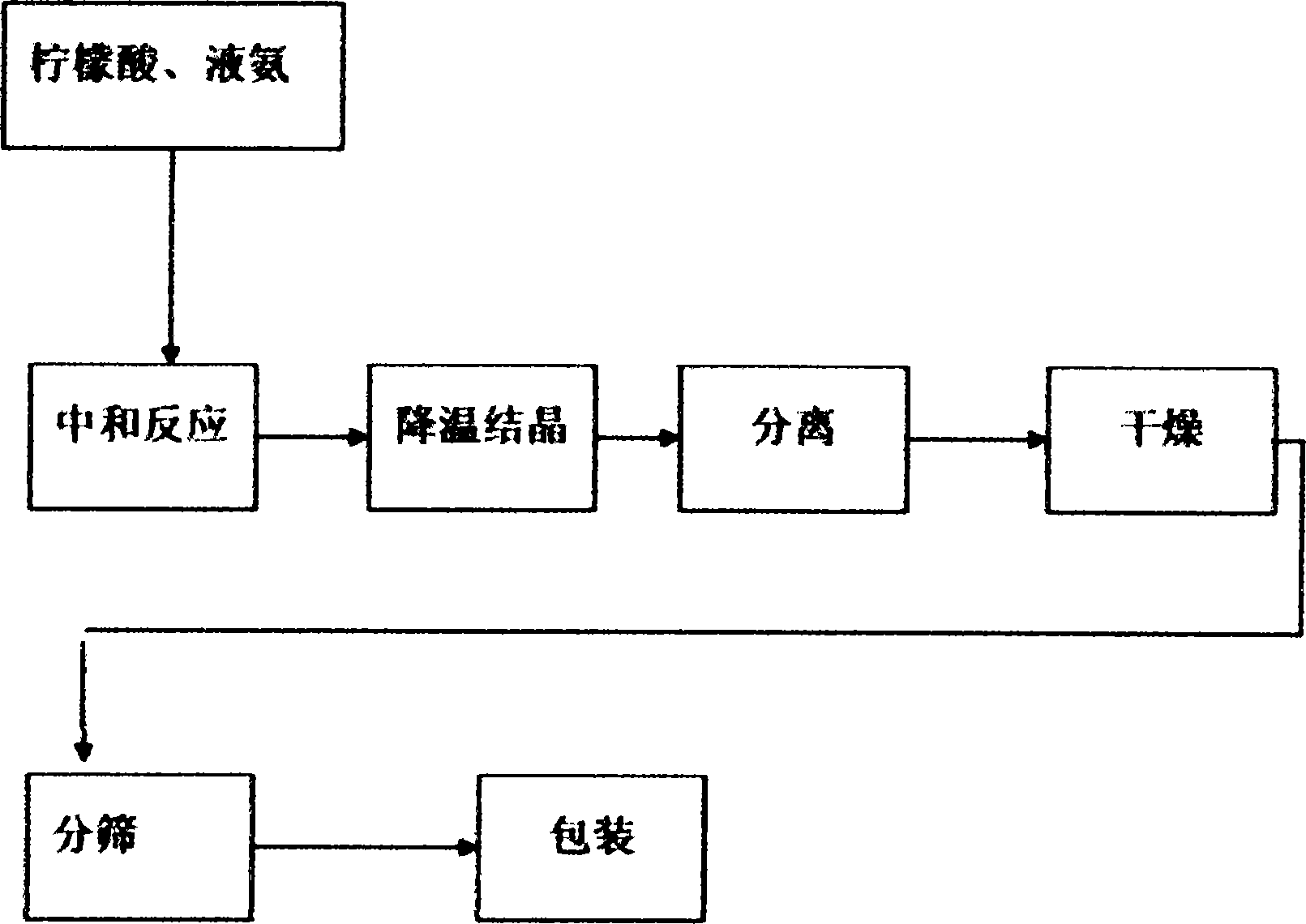

[0018] refer to figure 1 , the present embodiment adopts the following technical scheme: its production process is:

[0019] (1), inject a certain volume of purified water into the reactor, and start stirring;

[0020] (2) Add clean citric acid to make an acid solution of about 50%, open the steam valve, and heat up to about 50°C to fully dissolve the acid;

[0021] (3), open the liquid ammonia valve, slowly feed liquid ammonia into the reactor;

[0022] (4), the reaction releases a large amount of heat, and the flow and speed are controlled so that the temperature does not exceed 75°C;

[0023] (5), adjust PH4.5-5.5, reach reaction terminal point, open cooling water valve and cool down;

[0024] (6) When the temperature drops below 30°C, a large amount of crystals are precipitated, and centrifugation begins;

[0025] (7), the separated solid is dried through a vibrating fluidized bed, and the mother liquor is recycled;

[0026] (8), pack after sub-sieving.

[0027] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com