Preparation method of benzaldehyde

A technology of benzaldehyde and cinnamaldehyde, which is applied in the field of preparation of natural benzaldehyde to achieve the effects of high ozone utilization rate, good naturalness and good reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

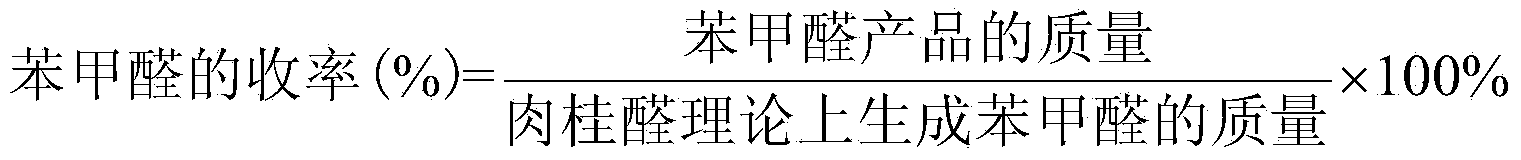

[0021] In the photocatalytic reactor, 10.0g of cinnamaldehyde (with a cinnamaldehyde content of more than 95%), 100.0g of anhydrous ethanol, 0.1g of TiO were respectively added 2 As a catalyst, ozone was introduced into the inner-illuminated photocatalytic reactor at a flow rate of 0.03g (ozone) / g (cinnamaldehyde) / h, and the ozonation reaction was carried out at -5°C for 0.5h to obtain crude benzaldehyde, which was heated at 80°C, Molecular distillation was carried out under the pressure of 160Pa to obtain 1.8 g of benzaldehyde product, and the yield of benzaldehyde was 22.4%.

Embodiment 2

[0023] In the photocatalytic reactor, 10.0g of cinnamaldehyde (with a cinnamaldehyde content of more than 95%), 60.0g of absolute ethanol and 0.2g of SnO were added respectively. 2 As a photocatalyst, ozone was introduced into the inner-illuminated photocatalytic reactor at a flow rate of 0.1 g (ozone) / g (cinnamaldehyde) / h, and the ozone cooperated with the photocatalytic reaction for 2 hours at 20 ° C to obtain crude benzaldehyde, at a temperature of 70 ° C. 2. Carry out molecular distillation under the pressure of 200Pa to obtain 3.5 g of benzaldehyde product, and the yield of benzaldehyde is 43.6%.

Embodiment 3

[0025] In the photocatalytic reactor, 10.0g of cinnamaldehyde (with a cinnamaldehyde content of more than 95%), 20.0g of anhydrous ethanol, and 0.3g of ZnO photocatalyst were added respectively, at a flow rate of 0.3g (ozone) / g (cinnamaldehyde) / h. Ozone was introduced into the inner-illuminated photocatalytic reactor, and the ozone cooperated with photocatalytic reaction for 3 hours at 5 °C to obtain crude benzaldehyde. Molecular distillation was carried out at a temperature of 50 °C and a pressure of 150Pa to obtain 4.7 g of benzaldehyde. The yield was 58.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com