A kind of self-contained water type concrete expansion agent and preparation method thereof

A technology of concrete and expansion agent, which is applied in the preparation of self-sufficient concrete expansion agent and in the field of self-sufficiency concrete expansion agent, which can solve the problems of increased drying shrinkage, difficulty in compensating the shrinkage effect of expansion agent, and decrease in concrete humidity, etc., to achieve improvement Anti-seepage performance, improvement of pumping construction performance, and effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

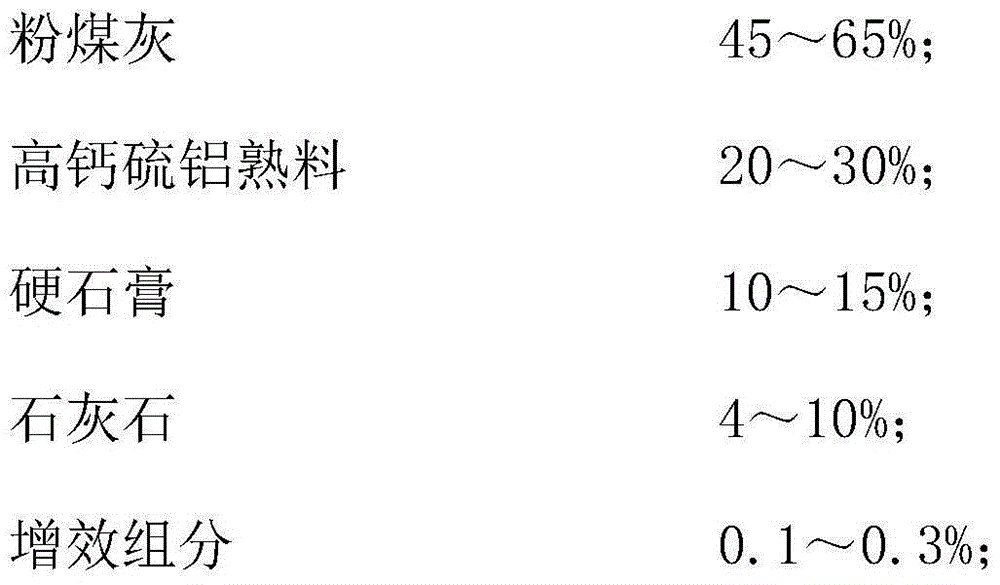

[0031] A kind of self-sufficient concrete expansive agent embodiment 1 of the present invention comprises following components, and each component is by mass percentage:

[0032]

[0033]

[0034] The high-calcium-sulfur-aluminum clinker is the product of limestone, gypsum, bauxite, and iron powder calcined at a temperature of 1400°C, and includes the following components, each of which is by mass percentage:

[0035]

[0036] Among them, Loss represents loss on ignition, R 2 O represents an oxide of an alkali metal. The mass percent of free CaO in the high-calcium-sulfur-aluminum clinker is 35.1%.

[0037] The synergistic component is a powdered sodium polyacrylate water-absorbing resin, and the sodium polyacrylate water-absorbing resin passes through a 200-mesh sieve with a residue ≤ 5.0%, soaked in a NaCl solution with a mass fraction of 0.9% for 60 minutes, and the sodium polyacrylate absorbs water The salt water absorption rate of the resin is 20-40g / g, the wat...

Embodiment 2

[0039] A kind of self-sufficient concrete expansive agent embodiment 2 of the present invention comprises following components, and each component is by mass percentage:

[0040]

[0041] The preparation method of the high-calcium-sulfur-aluminum clinker, synergistic components and the self-contained concrete expansion agent is the same as that in Example 1.

Embodiment 3

[0042] A kind of self-sufficient concrete expansive agent embodiment 3 of the present invention comprises following components, and each component is by mass percentage:

[0043]

[0044] The preparation method of the high-calcium-sulfur-aluminum clinker, synergistic components and the self-contained concrete expansion agent is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com