Treatment method for wastewater containing high-concentration organic phosphorus

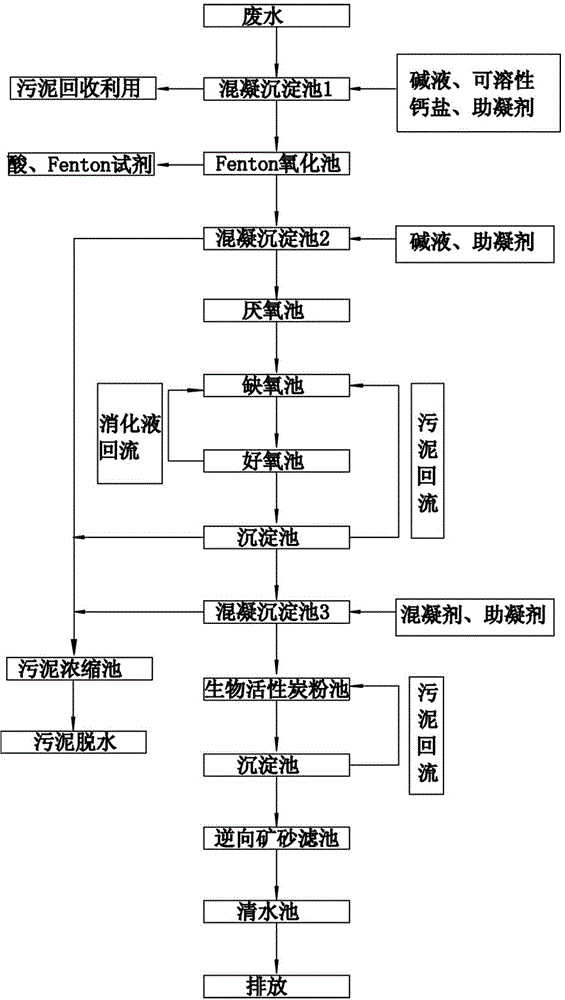

A treatment method, organic phosphorus technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as wastewater treatment not up to standard, achieve stable operation, simple and convenient operation , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The wastewater produced by a water treatment agent manufacturer contains more than 20 kinds of organic phosphorus scale and corrosion inhibitors, with a COD of about 3000 mg / L and a total phosphorus of about 1200 mg / L.

[0030] Add calcium hydroxide emulsion to the coagulation sedimentation tank 1 to adjust the pH value of the wastewater to 9.0, add a calcium chloride solution with a Ca / P equivalent ratio of 0.1 times, continue stirring for 40 minutes, and add 2 ppm of anionic PAM with a content of 0.1%. solution, stir evenly, settle on the inclined plate for 2 hours, and the effluent enters the fenton oxidation pool.

[0031]Use sulfuric acid to adjust the pH value to 3.5 in the outlet water, add ferrous sulfate heptahydrate at an amount of 1.2g / L, add 30% hydrogen peroxide at an amount of 2ml / L, stir and react for 80min, and the outlet water enters the coagulation sedimentation tank 2. Add sodium hydroxide solution to the wastewater to adjust the pH value to 9.0 to pr...

Embodiment 2

[0037] The wastewater produced by a water treatment agent manufacturer contains more than 20 kinds of organic phosphorus scale and corrosion inhibitors, with a COD of about 3000 mg / L and a total phosphorus of about 1200 mg / L.

[0038] Add calcium hydroxide emulsion to the coagulation sedimentation tank 1 to adjust the pH value of the wastewater to 9.5, add a calcium chloride solution with a Ca / P equivalent ratio of 0.1 times, continue stirring for 60 minutes, and add 2ppm of anionic PAM with a content of 0.1%. The solution was stirred evenly, the inclined plate settled for 2 hours, and the effluent entered the fenton oxidation pool.

[0039] Use sulfuric acid to adjust the PH value to 4.0 in the outlet water, add ferrous sulfate heptahydrate at an amount of 1.5g / L, add 30% hydrogen peroxide at an amount of 2.2ml / L, stir and react for 65min, and the outlet water enters the coagulation sedimentation tank 2. Add sodium hydroxide solution to the wastewater to adjust the pH value t...

Embodiment 3

[0045] The wastewater produced by a water treatment agent manufacturer contains more than 20 kinds of organic phosphorus scale and corrosion inhibitors, with a COD of about 3000 mg / L and a total phosphorus of about 1200 mg / L.

[0046] Add calcium hydroxide emulsion to the coagulation sedimentation tank 1 to adjust the pH value of the wastewater to 10, add a calcium chloride solution with a Ca / P equivalent ratio of 0.1 times, continue stirring for 40 minutes, and add 2ppm of anionic PAM with a content of 0.1%. The solution was stirred evenly, the inclined plate settled for 2 hours, and the effluent entered the fenton oxidation pool.

[0047] Adjust the pH value of the effluent to 3.5 with sulfuric acid, add ferrous sulfate heptahydrate at an amount of 3g / L, add 30% hydrogen peroxide at an amount of 4ml / L, stir and react for 70min, and the effluent enters the coagulation sedimentation tank 2. Add sodium hydroxide solution to the wastewater to adjust the pH value to 8.0 to produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com