Pretreatment method of nonionic surfactant wastewater

A non-ionic surface and active agent technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increasing the concentration of pollutants, unsatisfactory treatment effect, and toxicity and other issues to achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

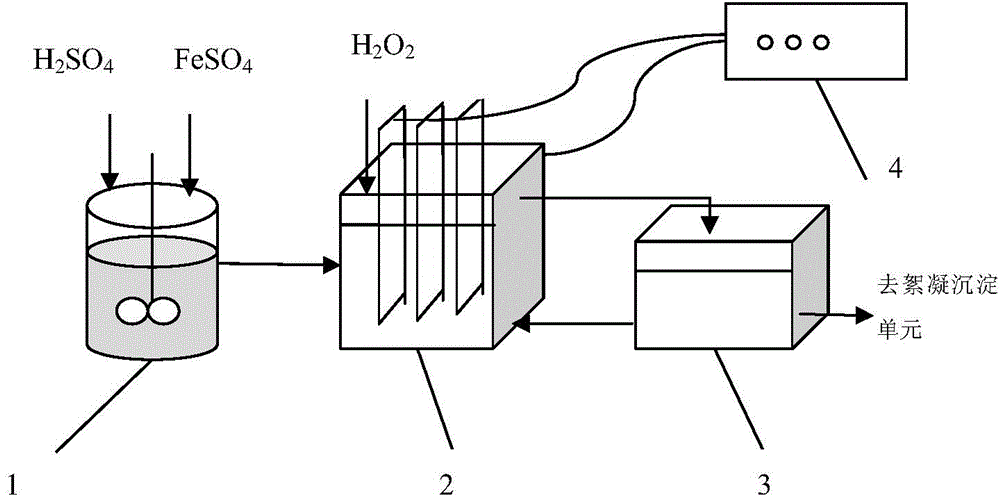

Image

Examples

Embodiment 1

[0032] The measured COD value of a simulated wastewater is 21782mg / L, the pH value is adjusted to 2.0, the FeSO4 addition amount is 600mg / L, and the H 2 o 2 The dosage is 75mg / L, the input current is set to 19.2A, the internal circulation ratio is set to 1:1, the residence time is 30min, the measured COD value of the effluent is 10073mg / L, and the removal rate is 53.8%.

Embodiment 2

[0034] The measured COD value of a simulated wastewater is 11036mg / L, the pH value is adjusted to 2.5, the FeSO4 addition amount is 500mg / L, and the H 2 o 2 The dosage is 30mg / L, the input current is set to 9.7A, the internal circulation ratio is set to 1:1, the residence time is 60min, the measured COD value of the effluent is 2106mg / L, and the removal rate is 80.9%.

Embodiment 3

[0036] The measured COD value of a simulated wastewater is 5367mg / L, the pH value is adjusted to 3.0, the FeSO4 addition amount is 400mg / L, and the H 2 o 2 The dosage is 7.5mg / L, the input current is set to 9.7A, the internal circulation ratio is set to 1:1, the residence time is 60min, the measured COD value of the effluent is 2553mg / L, and the removal rate is 52.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com