A kind of dry mix tile and production method

A production method and technology for ceramic tiles, applied in the field of architectural ceramic tiles, can solve the problems of inability to meet the production requirements of high-quality ceramic products, no clear graininess of ceramic tile products, uneven distribution of powder materials, etc., and achieve rich decorative effects, bright working environment, Evenly mixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

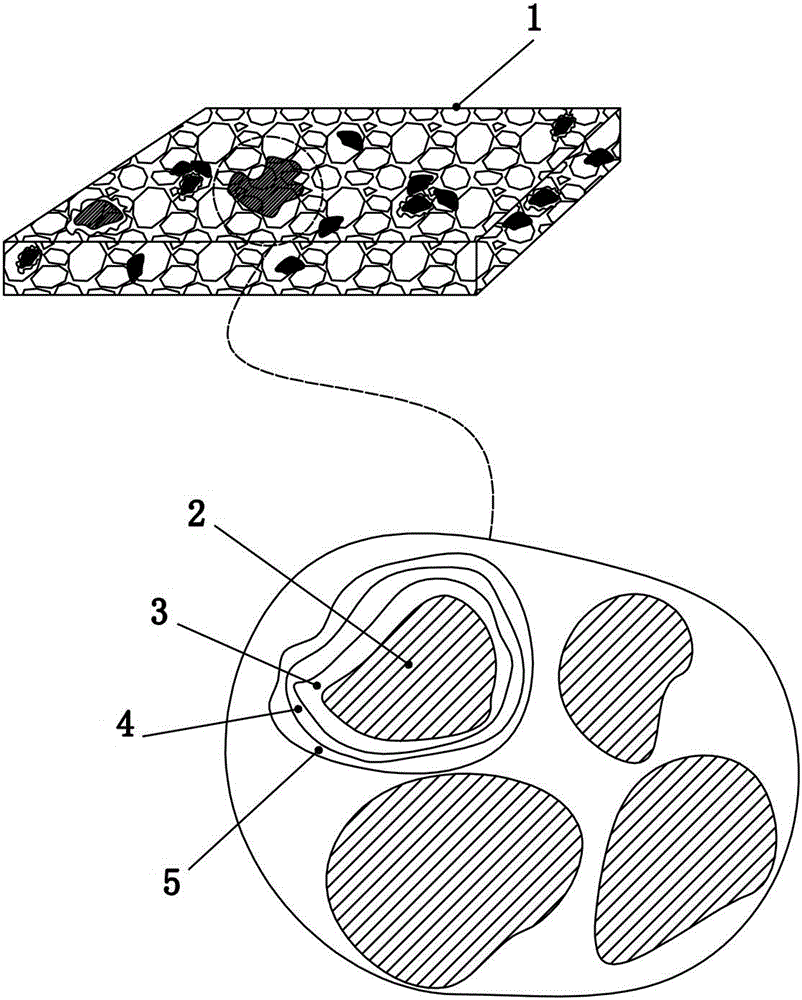

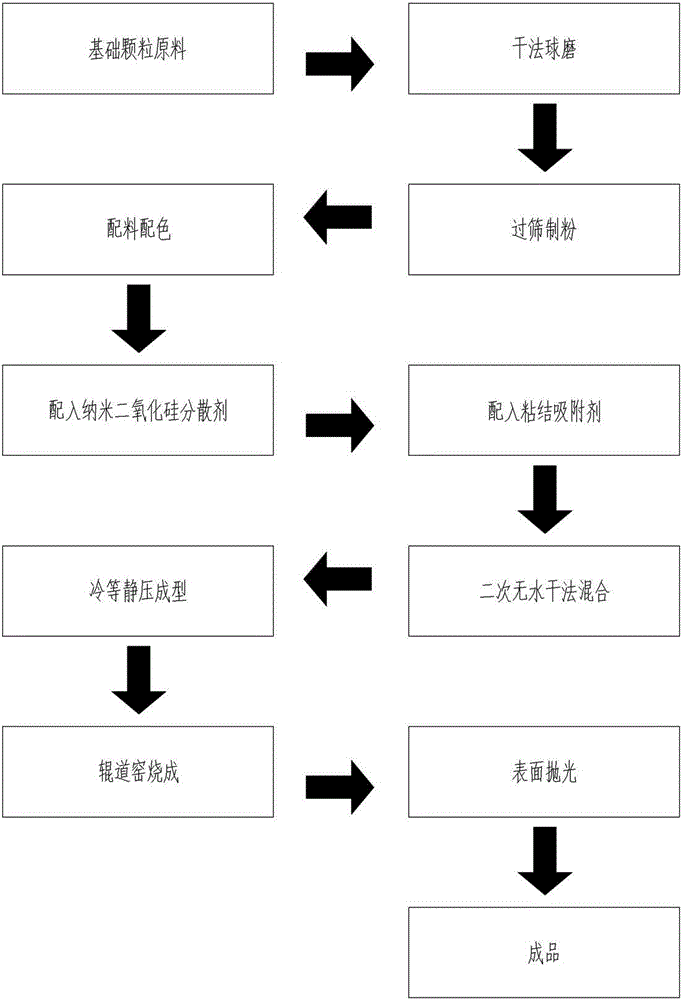

[0032] Example 1. In this example, the production steps are: three-dimensional premixing of basic particle raw materials - dry ball milling - sieving powder making - batching and color matching - adding nano-silica dispersant - adding bonding adsorbent - secondary anhydrous dry method Mixing - Cold Isostatic Pressing - Roller Kiln Firing - Surface Polishing.

[0033] Among them, the weight percentage of the basic particle raw material formula is: 30% of raw ore powder, 25% of raw ore black mud, 5% of inorganic ceramic pigments, 35% of waste materials in ceramic factories, 0.5% of nano-ultrafine silica dispersant, bonding adsorbent 4.5%. The mixing is premixed in a three-dimensional mixing method. After ball milling, the ingredients are mixed and matched, and then the nano-dispersant anhydrous dry mixing technology is used for the second three-dimensional mixing. The bonding strength between the nano-ultrafine silica material and the powder particles , dispersion and other pr...

Embodiment 2

[0034] Example 2. In this example, the production steps are: three-dimensional premixing of basic particle raw materials - dry ball milling - sieving powder making - batching and color matching - adding nano-silica dispersant - adding bonding adsorbent - secondary anhydrous dry method Mixing - cold isostatic pressing forming - roller kiln firing - surface polishing, to obtain ceramic tile products with uniform and stable particle distribution.

[0035] Among them, the weight percentage of the basic particle raw material formula is: 40% of raw ore powder, 15% of raw ore black mud, 3% of inorganic ceramic pigments, 37% of waste materials in ceramic factories, 2.5% of nano-ultrafine silica dispersant, and bonding adsorbent 2.5%. The mixing is premixed by three-dimensional mixing method. After ball milling, the ingredients are mixed and matched, and then the nano-silica dispersant anhydrous dry mixing technology is used for the second three-dimensional mixing. The nano-ultrafine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com