Comprehensive utilization method of high titanium slag

A high-titanium type, slag technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of large alkali consumption, high energy consumption, high energy consumption, etc., to reduce the cost of acid consumption, improve production efficiency and Economic benefits, the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

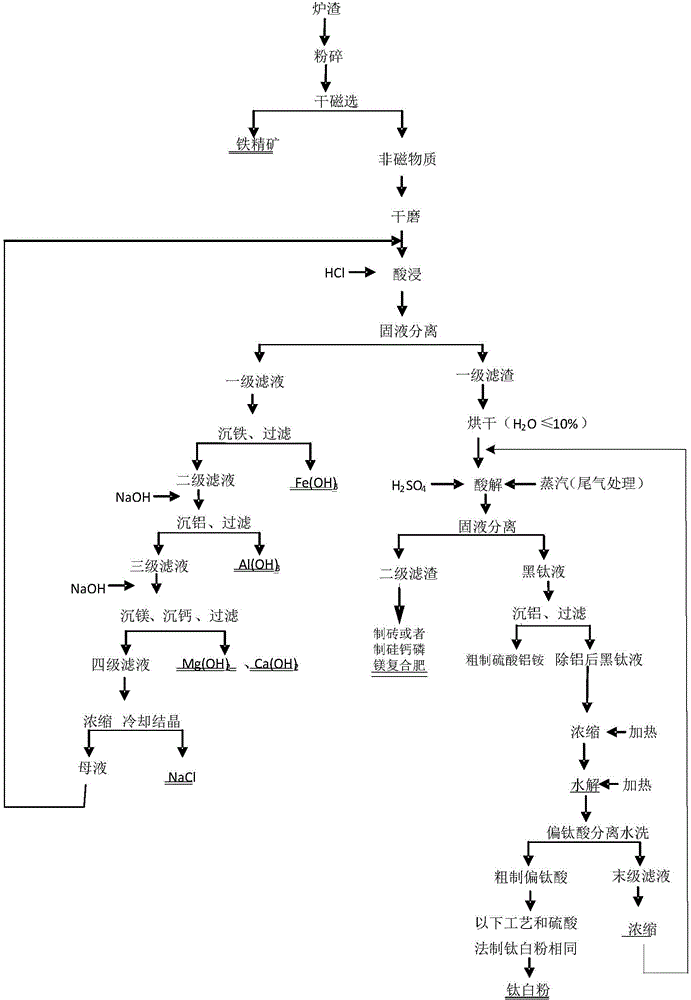

[0087] A comprehensive utilization method of high-titanium slag, such as figure 1 shown, including the following steps:

[0088] (1) Pretreatment: the slag is processed to obtain the slag powder after iron removal;

[0089](2) The first stage of leaching: the slag powder after iron removal is pickled with dilute hydrochloric acid, and the solid-liquid separation (sedimentation, filtration) after the acid leaching obtains the first-level filter residue and the first-level filtrate;

[0090] (3) The second stage of leaching: after the primary filter residue is dried, acidolysis is carried out with dilute sulfuric acid, and solid-liquid separation (sedimentation, filtration, pressure filtration, etc.)

[0091] (4) Titanium dioxide production: black titanium solution is processed to produce titanium dioxide.

[0092] Because dilute hydrochloric acid was used for acid leaching first, the structure of slag particles changed greatly after immersion in dilute hydrochloric acid. Due ...

Embodiment 2

[0097] On the basis of embodiment 1, further provide the preferred technique when adopting dilute sulfuric acid to carry out acidolysis:

[0098] Dilute sulfuric acid preferably adopts 40%-45% (mass fraction) H 2 SO 4 , more preferably 40% (mass fraction) H 2 SO 4 ;

[0099] The second stage leaching is preferably carried out in two steps:

[0100] One-time leaching operation condition and method: sulfuric acid consumption: suppose ore weight is W, and the concentration of dilute sulfuric acid is 40% (mass fraction), then the dilute sulfuric acid consumption is: 1.4w * 80% ÷ 40%=2.8w. (Note: 1.4T of concentrated sulfuric acid with a concentration of 97% is required for each 1T of slag, and the amount of dilute sulfuric acid used in the first leaching is 80% of the total amount of dilute sulfuric acid used in the second stage leaching)

[0101] Firstly add the primary filter residue into the enamel reaction kettle, then slowly add the dilute sulfuric acid solution (do not ...

Embodiment 3

[0109] Further, on the basis of Example 1 or Example 2, the steps for processing the black titanium solution to prepare titanium dioxide are given:

[0110] Add saturated ammonium sulfate solution to the black titanium solution, preferably add 20 liters of saturated ammonium sulfate solution per 1m3 black titanium solution, to precipitate crude aluminum ammonium sulfate from the solution, remove the crude aluminum ammonium sulfate, and then heat, concentrate and hydrolyze the solution , and then separated and washed with water to obtain crude metatitanic acid and the final filtrate. The final filtrate contains the remaining waste acid from acidolysis. The obtained final filtrate is concentrated and regenerated and then added to the acid hydrolysis step for recycling. Titanium acid is used as raw material to prepare titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com