Thin-wall foam carbon material with nanoscale wall thickness and preparation method thereof

A nano-scale, foamed carbon technology, applied in the field of foamed carbon materials and its preparation, can solve the problems of harsh process conditions, thick carbon wall, complicated operation, etc., and achieve the effects of simple operation, time saving, promotion of carbonization, and stable heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the thin-walled foamed carbon material of above-mentioned nanoscale wall thickness, comprises the steps:

[0040] (1) Dispersing cornstarch in an acidic aqueous solution and dipping it to obtain a cornstarch slurry; the slurry uses the pitting hydrolysis of the cornstarch by the acid solution to make holes in the cornstarch granules;

[0041] (2) Suction filter the corn starch slurry to obtain a filter cake;

[0042] (3), drying filter cake;

[0043](4) Put the dried filter cake in a non-metallic heat-resistant closed container equipped with a microwave absorber. The total volume of the starch granules should be much smaller than the volume of the container, and then fill it with an inert protective gas;

[0044] (5) Put the container in the microwave field, and use the microwave to heat the starch granules in the container rapidly, so that a large amount of decomposition gas is generated inside the starch granule in a short time, and the deco...

Embodiment 1

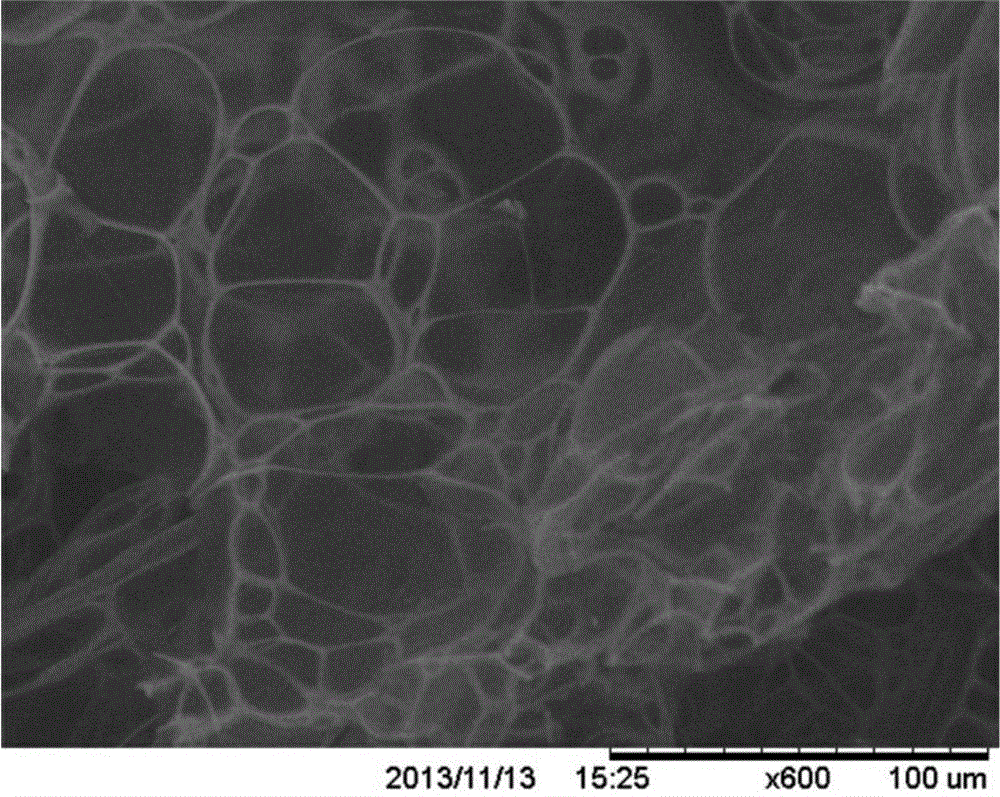

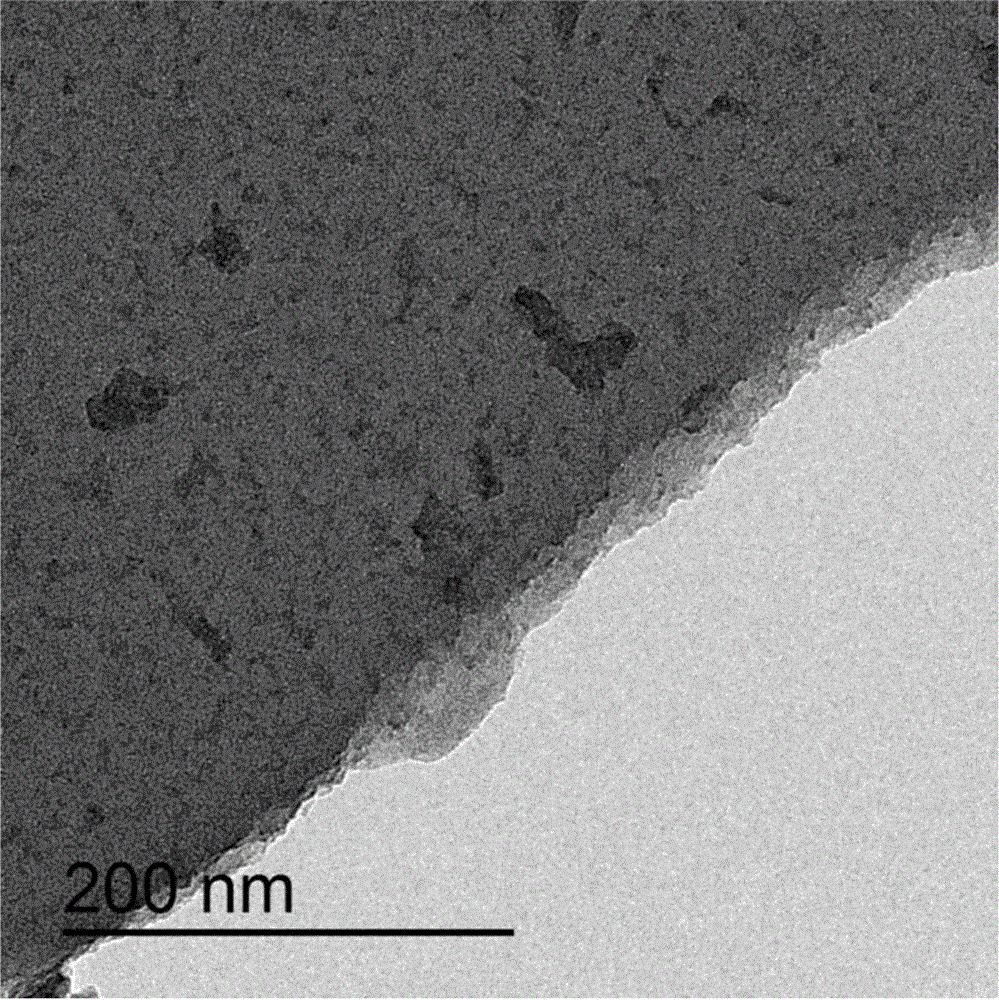

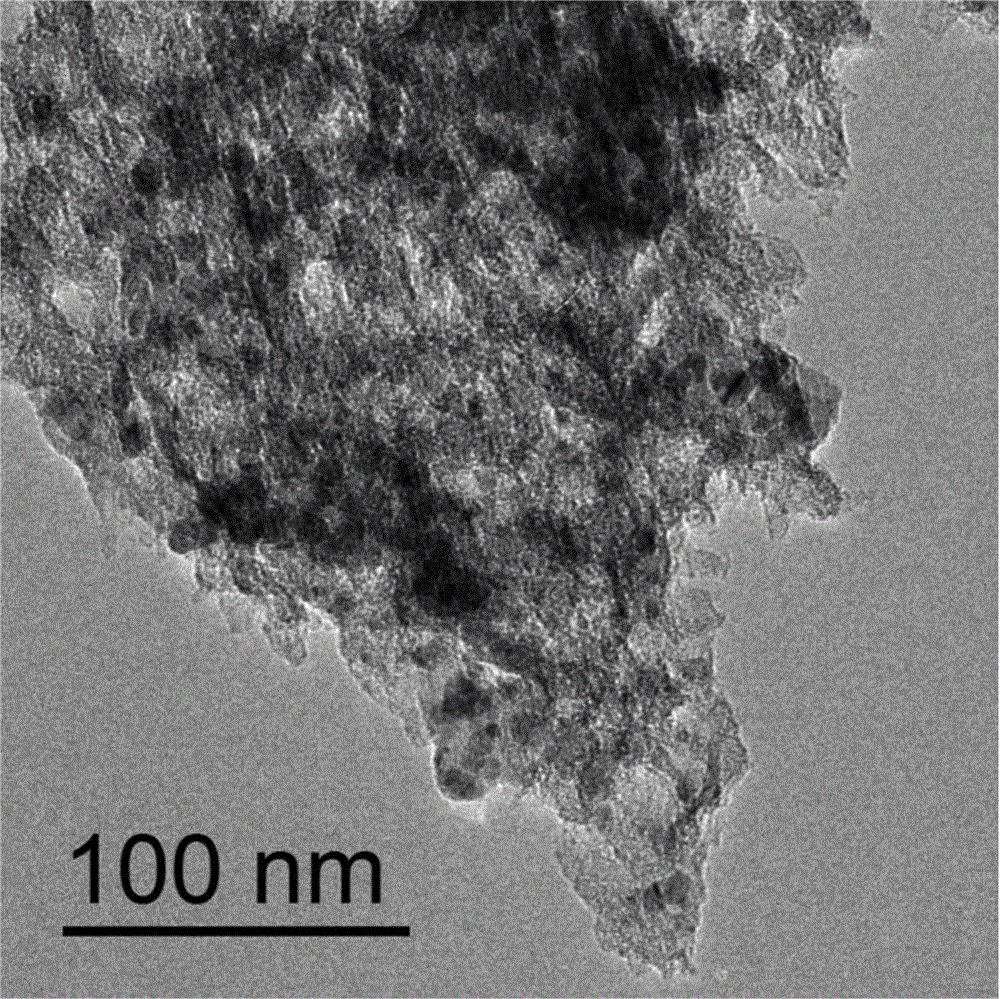

[0056] Firstly, 5 g of corn starch was dispersed in 50 mL of an aqueous solution containing 1 mol / L sulfuric acid and 1 mol / L phosphoric acid, soaked for 3 h and then suction filtered, and then the filter cake was dried in an oven at 100 °C for 3 h. Weigh 2 g of the above-mentioned dried starch into a quartz crucible with an inner diameter of 2.5 cm and a height of 5 cm, and then place the quartz crucible in another quartz crucible with an inner diameter of 5.0 cm and a height of 8.0 cm that is equipped with a microwave absorber of ferric oxide In, and make ferric oxide evenly filled between two quartz crucibles. Fill the crucible with nitrogen protection, cover the crucible lid, and then heat it in a Galanz microwave oven WG700TL2011-K6 at high heat for 2 min and then cool to room temperature. The obtained product was washed with distilled water until neutral, and finally dried in an oven at 100 °C for 3 h to obtain a thin-walled carbon foam material with nanometer wall thick...

Embodiment 2

[0059] First, 5 g of corn starch was dispersed in 50 mL of an aqueous solution containing 1 mol / L sulfuric acid, 1 mol / L phosphoric acid, and 0.4 mol / L zinc chloride, soaked for 3 h, and then suction-filtered, and then the filter cake was placed in an oven at 100 °C. Dry for 3 h. Weigh 2 g of the above-mentioned dried starch into a quartz crucible with an inner diameter of 2.5 cm and a height of 5 cm, and then place the quartz crucible in another quartz crucible with an inner diameter of 5.0 cm and a height of 8.0 cm that is equipped with a microwave absorber of ferric oxide In, and make ferric oxide evenly filled between two quartz crucibles. Fill the crucible with nitrogen protection, cover the crucible lid, and then heat it in a Galanz microwave oven WG700TL2011-K6 at high heat for 2 min and then cool to room temperature. The obtained product was soaked in 1 mol / L sulfuric acid for 1 h, filtered and then washed with distilled water until neutral, and the final product was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com