A construction site environmental protection and energy saving assembled automatic car washing equipment

An automatic car washing, environmental protection and energy-saving technology, applied in the direction of vehicle external cleaning devices, etc., can solve the problems of high labor intensity, water cannot be recycled, and time-consuming, etc., to achieve the effect of purifying the construction environment, saving car washing water, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

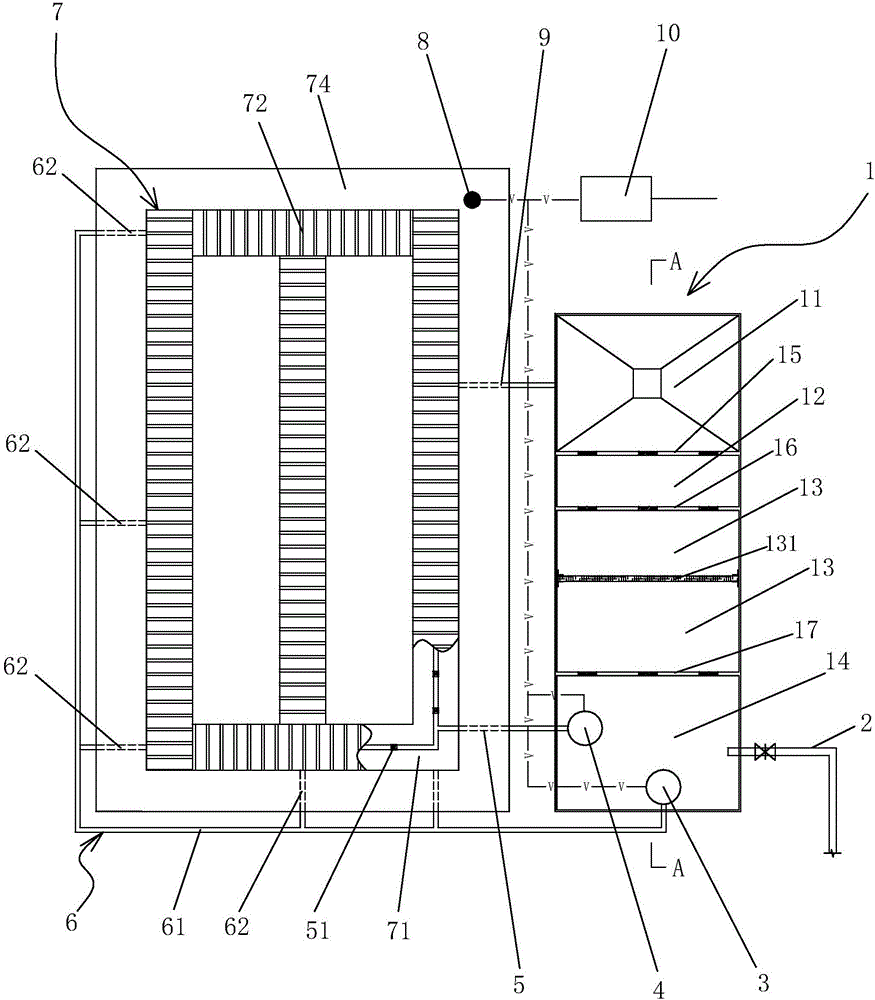

[0026] Such as figure 1 As shown, the present invention is an environmentally friendly and energy-saving assembly type automatic car washing equipment for construction sites. , infrared probe 8 and control box 10.

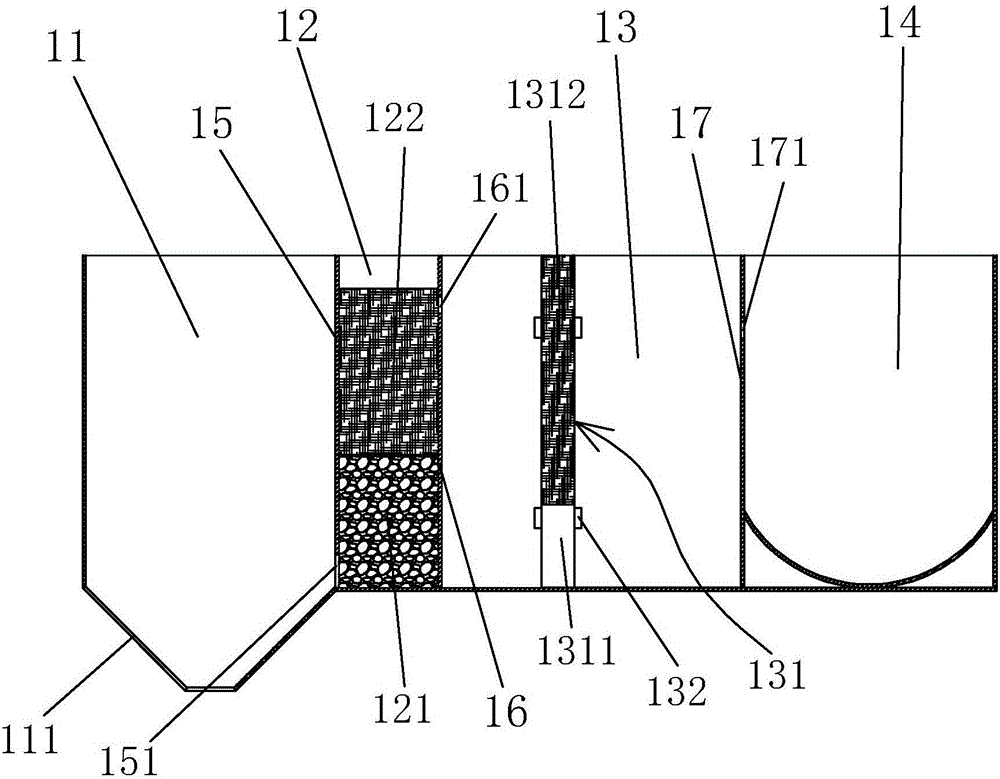

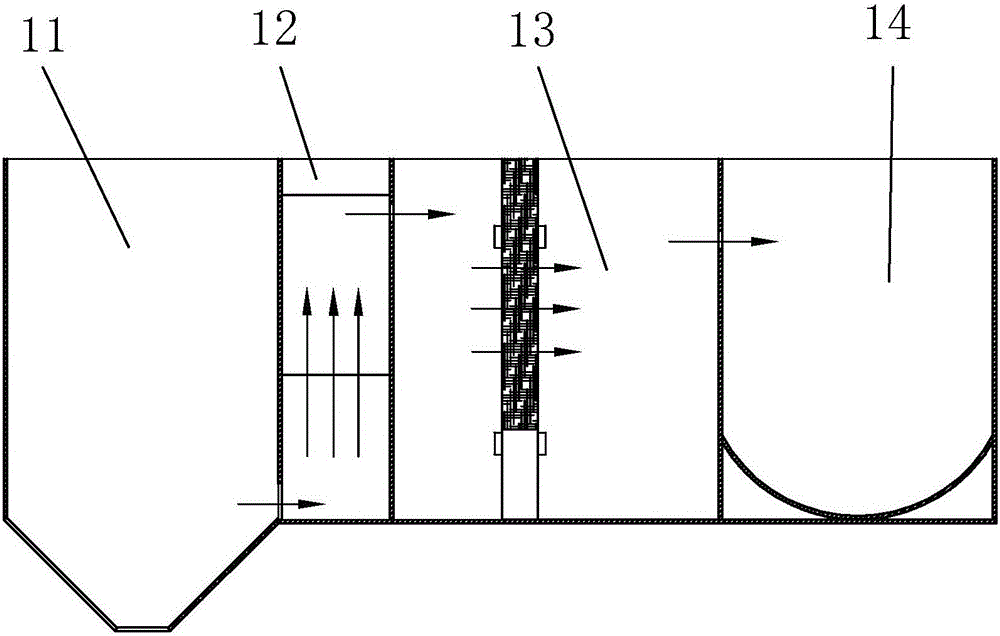

[0027] Such as figure 2 As shown, the pool 1 includes a mud pool 11, a water filter 12, a water barrier 13 and a water pool 14 arranged in sequence, and the mud pool 11 and the water filter 12 are separated by a steel plate partition I15, and the water filter 12 and the water filter 12 are separated by a steel plate partition I15. The water barriers 13 are separated by steel plate partition II16, and the water barriers 13 and reservoirs 14 are separated by steel plate partition III17. The lower end of the steel plate partition I15 is provided with a plurality of drain holes I151, and the upper end of the steel plate partition II16 is provided with There are multiple drain holes II161, and the upper end of the steel plate partition III17 is provided with multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com