Multifunctional drill bit

A multi-functional, drill bit technology, applied in drilling/drilling equipment, drill repair, drilling tool accessories, etc., can solve the problem of low efficiency of header (pipe) tube hole and groove processing, unfavorable large-scale use of workshops, etc. problems, to achieve the effect of high practicability and versatility, low manufacturing cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

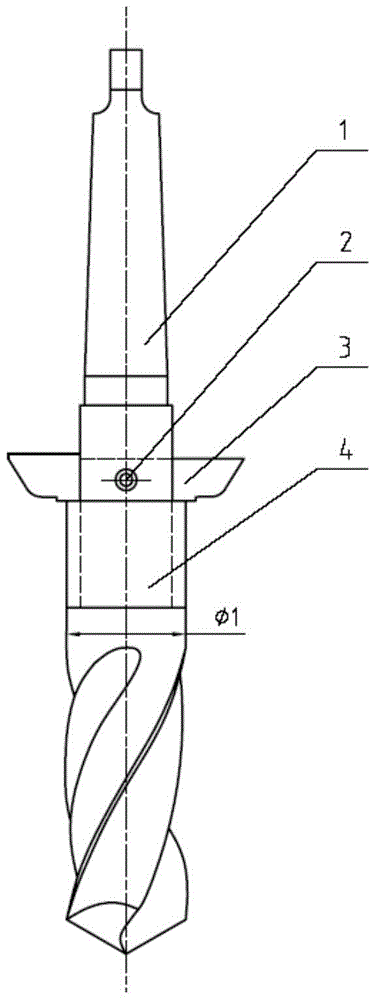

[0033] Example 1, such as figure 1 As shown, a multifunctional drill-scraping drill bit includes a drill body 1, a hexagon socket head screw 2, a forming scraper 3, and a liner 4.

[0034] The specific connection is as follows: the liner 4 is installed on the drill body 1, the forming scraper 3 is installed in the square hole on the drill body 1, and is tightened and fixed by the hexagon socket head cap screw 2.

[0035] The operation steps are as follows:

[0036] 1. Determine the hole and groove size of the header (pipe) to be processed, and select the corresponding forming scraper 3. Then install the liner 4 in the drill body 1 (the outer diameter of the liner 4 is designed to be tapered, and attention should be paid to the installation direction during installation. The bottom diameter of the liner 4 is larger than the upper diameter). Afterwards, the forming scraper 3 is installed, and is tightened and fixed by the hexagon socket head cap screw 2. That is: after comple...

Embodiment 2

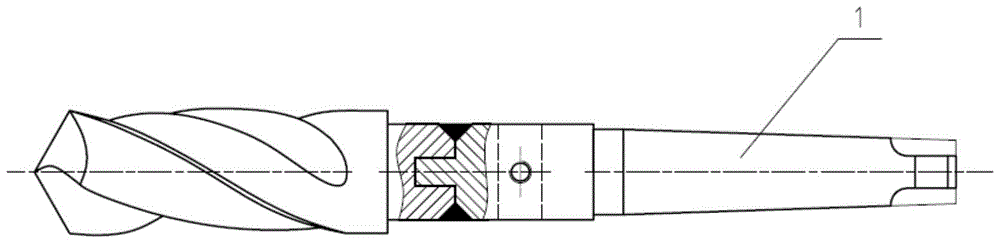

[0038] Example 2, such as Figure 5 As shown, another multifunctional drill bit includes a drill body 1, a hexagon socket head cap screw 2, a plug 5, and a sleeve reamer 6.

[0039] The specific connection is as follows: the sleeve reamer 6 is installed on the drill body 1, and the plug 5 is installed in the square hole on the drill body 1, so that the synchronous rotation of the sleeve reamer 6 and the drill body 1 is restricted, and the plug 5 passes through the hexagon socket head screw. 2 Tighten and fix.

[0040] The operation steps are as follows:

[0041] 1. The initial installation operation is the same as the implementation of the first operation, the difference is that the sleeve reamer 6 is used instead of the liner 4, and the plug 5 is used instead of the forming scraper 3.

Embodiment 3

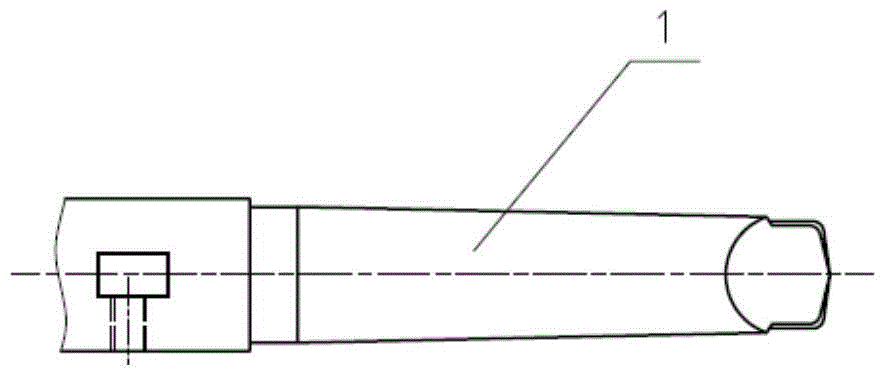

[0043] Example 3, such as Figure 8 As shown, a multifunctional drill bit includes a drill body 1, a hexagon socket head screw 2, a forming scraper 3, and a sleeve reamer 6;

[0044] The specific connection is as follows: the sleeve reamer 6 is installed on the drill body 1, so that the sleeve reamer 6 and the drill body 1 are limited to rotate synchronously; the forming scraper 3 is installed in the square hole on the drill body 1, and the forming scraper 3 is tightened and fixed by the hexagon socket head cap screw 2, and the forming scraper 3 is provided with an installation limit step.

[0045] The operation steps are as follows:

[0046] The initial installation operation is the same as the implementation of the first operation, the difference is: the sleeve reamer 6 is used instead of the liner 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com