Flip-casting mold

A flip-type, mold technology, applied in the direction of manufacturing tools, mold handling equipment, casting molding equipment, etc., can solve the problems of inconvenient, compact and narrow operating space, and the design of the distance between the movable mold and the mold opening will not be too large. , to achieve the effect of easy coating and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

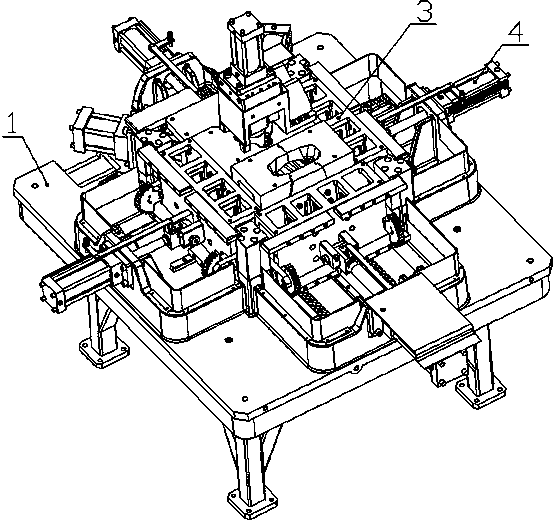

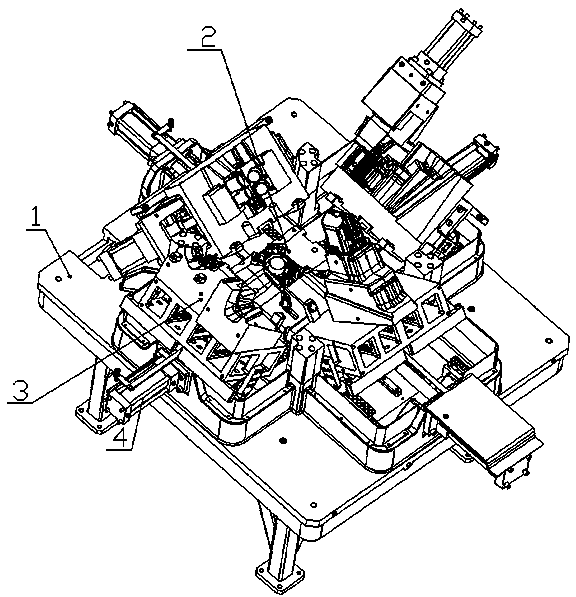

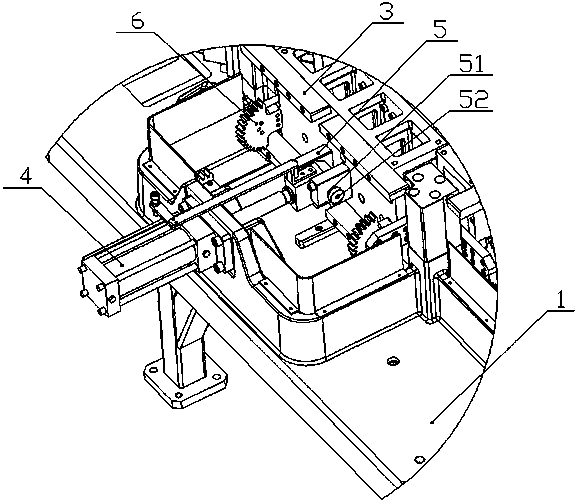

[0025] see Figure 1-Figure 6 , as shown in the legend therein, a flip-type pouring mold includes a workbench 1, a fixed mold and four movable mold devices, the fixed mold is a bottom mold 2 arranged on the workbench, and the movable mold device It includes a side mold 3 arranged on one side of the bottom mold 2 and a hydraulic cylinder 4 arranged on the workbench 1 and on the driving side of the side mold 3. The side mold 3 has a horizontal mold opening and closing direction, and the driving direction of the hydraulic cylinder The same as the above mold opening and closing direction,

[0026] A connecting plate 5 is arranged on the driving side of the side mold 3, and the connecting plate 5 is rotatably connected with the driving end of the hydraulic cylinder 4 and forms a rotation axis extending in the horizontal direction;

[0027] Side mold 3 also comprises turning mechanism, and this turning mechanism comprises the gear 6 that is arranged on the drive side of side mold 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com