Steel splitting device for cooling bed

A cooling bed and steel tooth technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve the problem of affecting the cooling efficiency of the rolled material, the straightness of the rolled material, the quality of the rolled product, the yield, and the quality of the rolled material. and other problems, to achieve the effect of easy fixed installation, low manufacturing cost, simple and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

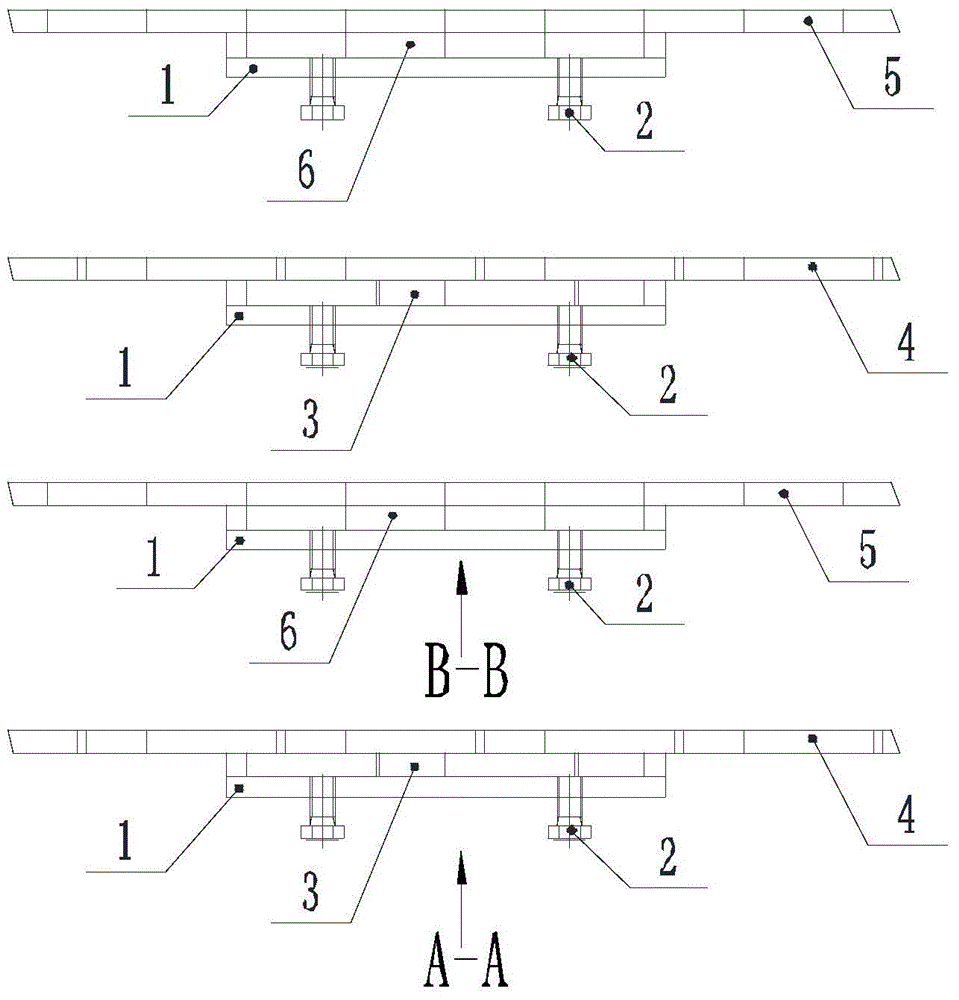

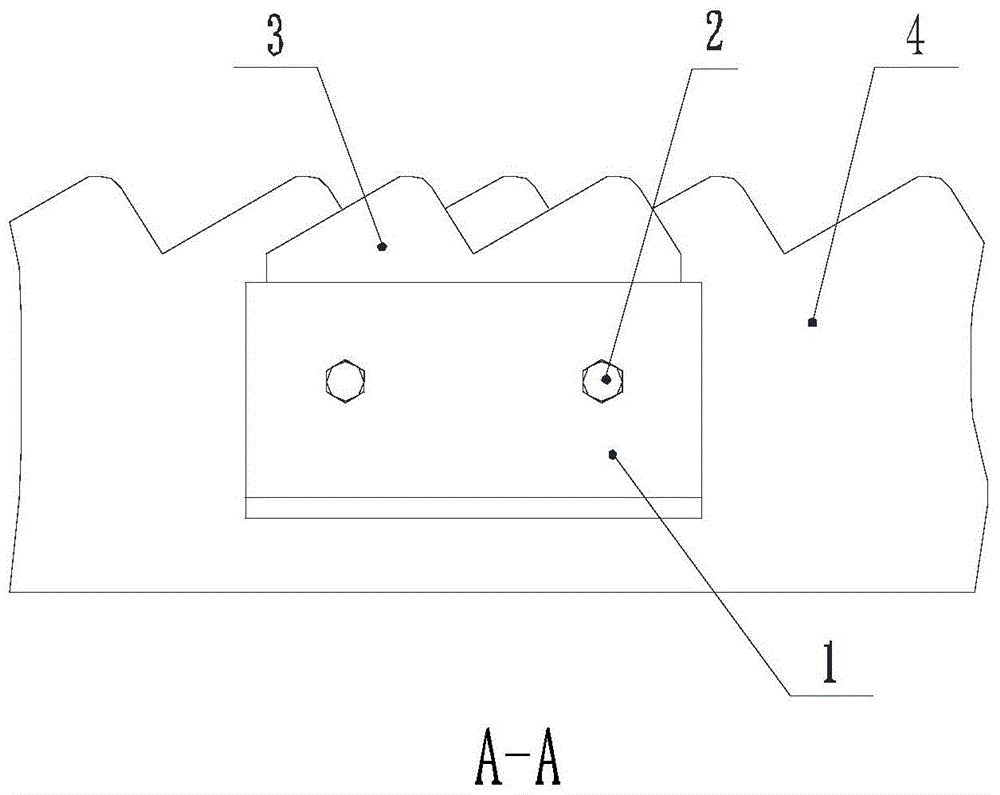

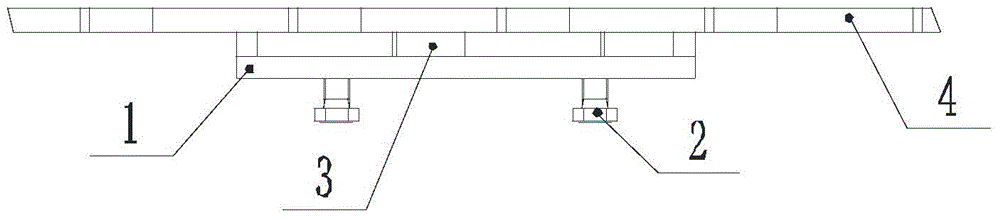

[0050] The sub-steel tooth plate of the present embodiment comprises a fixed-tooth sub-steel plate 3 fixed on the cooling bed fixed rack 4 and a movable-tooth sub-steel plate 6 fixed on the cooling bed movable rack 5; the fixed-tooth sub-steel plate 3 has The fixed tooth plate is divided into steel teeth 31, and the fixed tooth plate is divided into steel teeth 31, which are arranged between the teeth of at least two teeth at the entrance of the fixed rack 4 of the cooling bed; , The movable tooth plate sub-teeth 61 is arranged between the teeth of at least two teeth at the entrance position of the movable tooth rack 5 of the cooling bed.

[0051] The fixed tooth plate sub-teeth 31 of this embodiment includes at least two, and the fixed tooth plate sub-teeth 31 are sequentially arranged between the teeth of the first tooth and the second tooth at the entrance position of the fixed rack 4 of the cooling bed; The moving tooth plate sub-teeth 61 and the fixed tooth plate sub-teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com