Driving tape-threading guide plate

A guide plate and belt threading technology, applied in the field of metallurgical steel rolling equipment, can solve problems such as thin strip steel stacking, and achieve the effects of preventing steel stacking, reducing frictional resistance, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

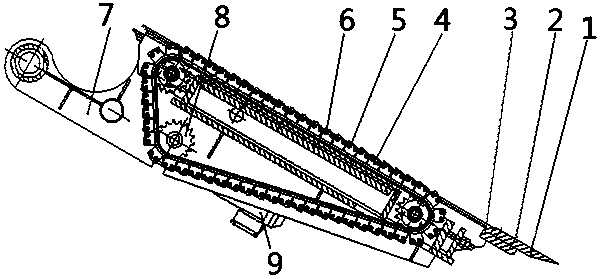

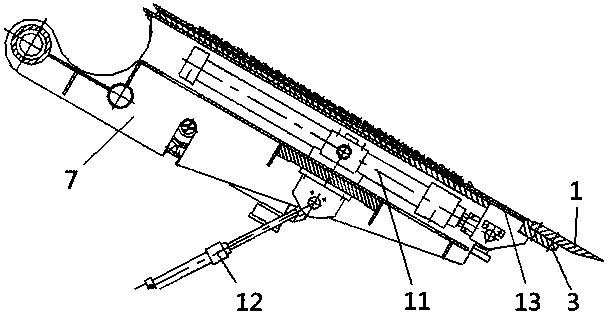

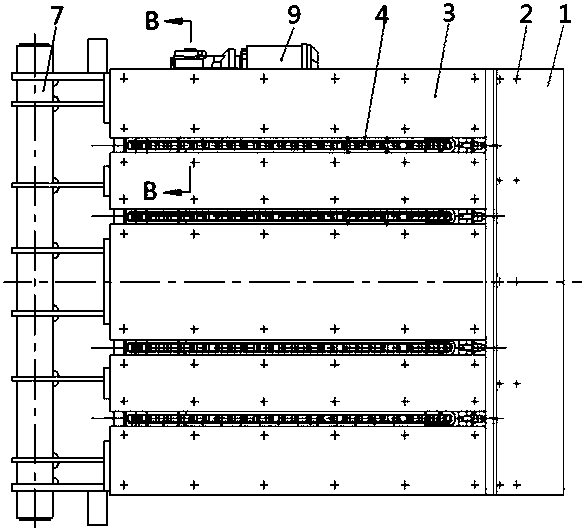

[0017] refer to figure 1 , figure 2 , Figure 4 , the structure of the present invention is, comprise the swing hydraulic cylinder 12 that is hinged on the leveler base and the swing guide frame 7, the piston rod head of the swing hydraulic cylinder 12 is hinged with the swing guide frame 7; A telescopic hydraulic cylinder 11 is installed in the form of a shaft, and the head of the piston rod of the telescopic hydraulic cylinder 11 is connected to the telescopic guide plate 3. The front end of the telescopic guide plate 3 is fixed with a scraper 1 by a screw 2. The surfaces are all paved with phenolic boards 13; multiple rows of roller chains 4 (four rows of roller chains 4 in the embodiment) are installed in the swing guide frame 7, and each row of roller chains 4 is correspondingly driven with a group of sprockets 8, A gear motor 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com