Ammonia Absorber and Ammonia Preparation Absorption System

A technology of ammonia absorber and ammonia water, which is applied in the preparation/separation of ammonia, chemical instruments and methods, and the separation of dispersed particles, etc., which can solve the problems that the structural composition cannot be changed and adjusted, the automatic sustainable production cannot be realized, and the ammonia gas absorption rate is high. problems, to achieve the effects of easy automatic control means, high quality ammonia water preparation, and high ammonia gas absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

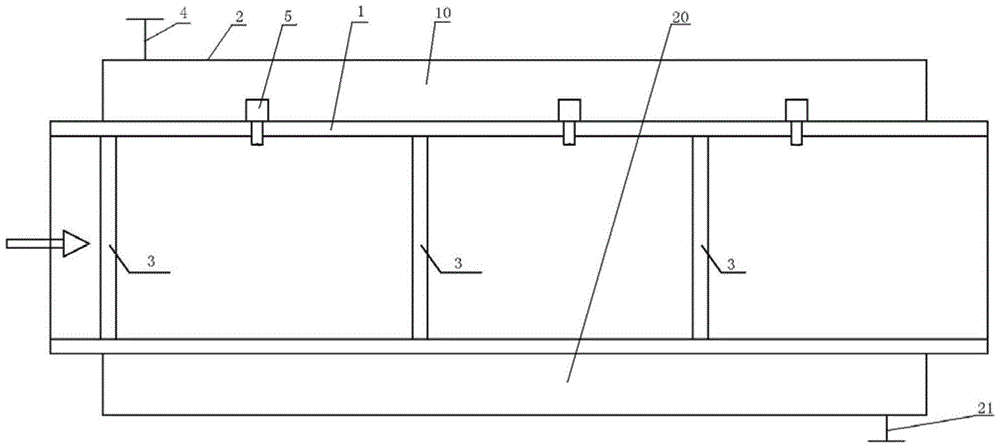

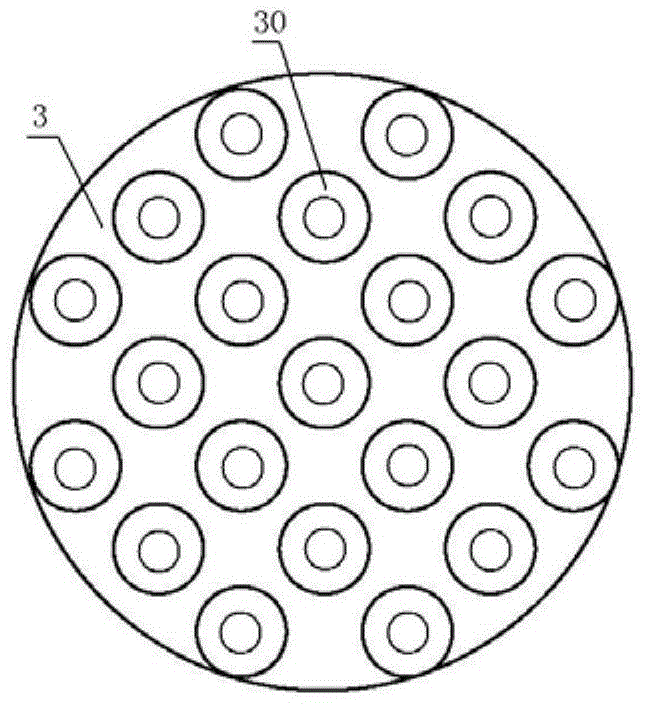

[0013] The ammonia absorber disclosed in the patent application for the present invention consists of at least one absorption unit, such as figure 1 The structure of an embodiment shown is composed of three absorption units connected in series. Each absorption unit is composed of an inner cylinder 1 and an outer cylinder 2 that are set inside and outside. The inner cylinder 1 and the outer cylinder 2 of adjacent absorption units are sequentially butted and extended axially. The inner cylinder 1 constitutes a guide channel for the circulation of ammonia gas. One end Input ammonia gas, and the inner cylinder ammonia gas access of each absorption unit is provided with a diffuser plate 3 in front, such as figure 1 As shown, it is a series connection of the inner cylinder port and the outer cylinder port of two adjacent absorption units. There are three diffuser plates 3 in the middle of the inner cylinder 1. The left side of each diffuser plate 3 is the absorption unit of this sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com