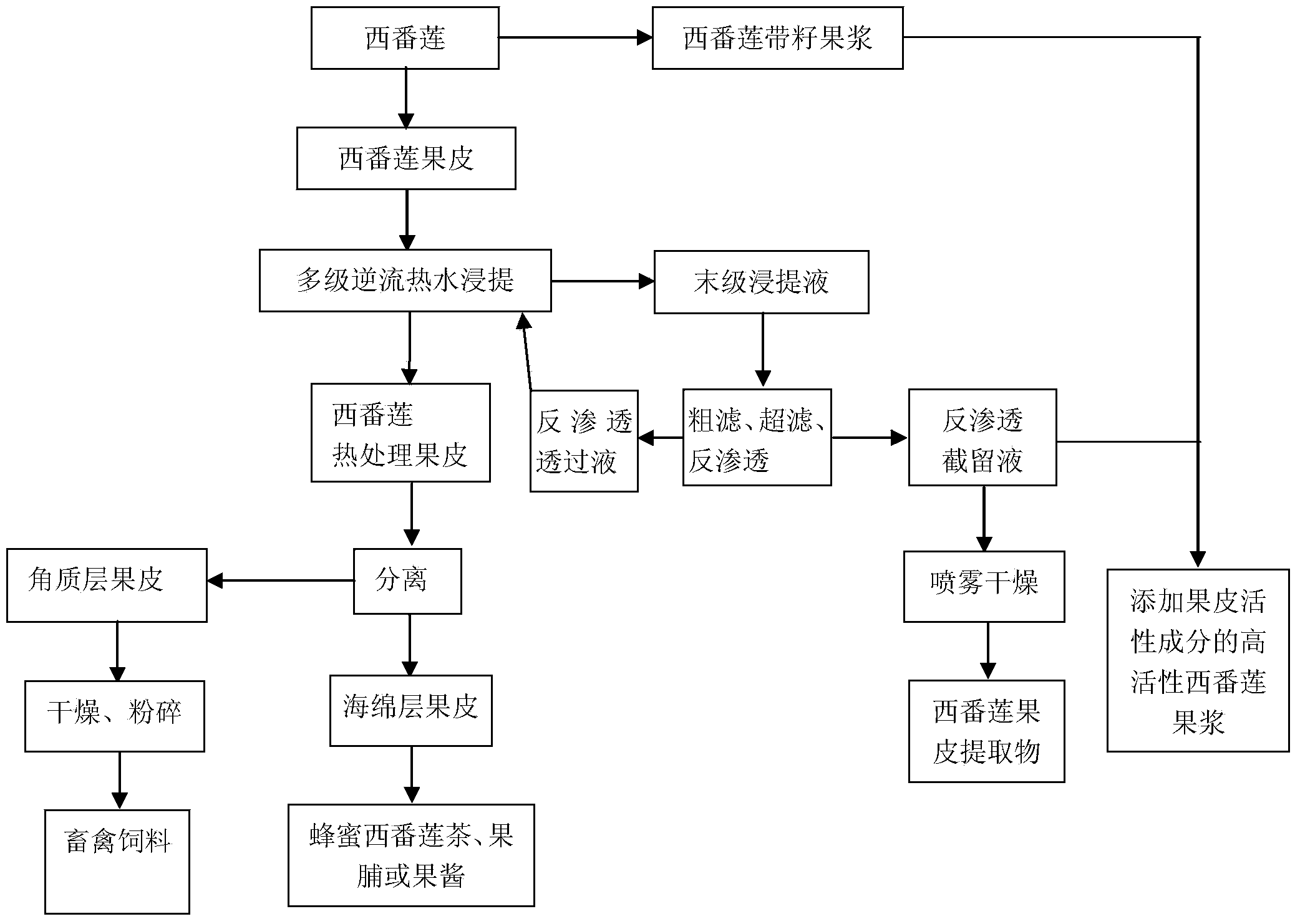

Full-utilization comprehensive processing process for improving value of passion fruit peels

A technology for comprehensive processing and passion fruit, applied in food processing, application, confectionery industry, etc., can solve problems such as limitations, and achieve the effect of reducing the use of processing water, enhancing dietary fiber, and highlighting flavor and taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] During the processing of passion fruit pulp, the raw materials of passion fruit are divided mechanically or manually, and after separating the pulp with seeds, half-divided passion fruit peels are obtained. The seeded pulp is processed into passion fruit pulp.

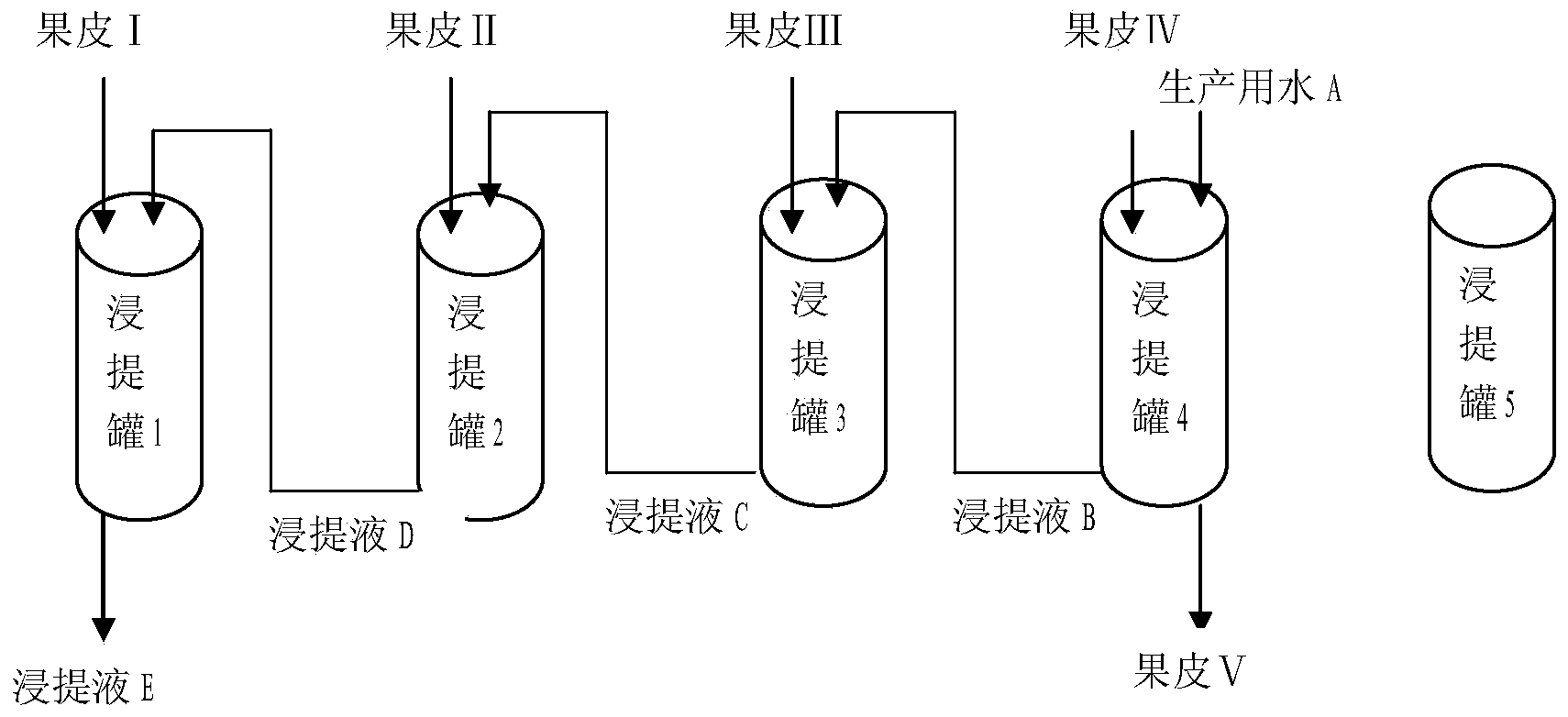

[0029] The passion fruit peel is placed in the extraction tank, and the four-stage countercurrent hot water extraction method is used for processing. The specific steps are: use 5 extraction tanks to form a production line, the weight ratio of the peels in each extraction tank to the production water is 1:8~1:10, extract for 3~6 minutes respectively, and the peels of each tank are in the tank. Afterwards, it is not discharged from the bottom of the tank until the fourth leaching is finished; while the production water flows between the tanks in a countercurrent manner for leaching, that is: after the passion fruit peel Ⅰ is loaded into the leaching tank 1, the water is extracted by the leaching tank 1. The extr...

Embodiment 2

[0033] After the passion fruit raw materials are purchased and accepted, the peels in half are obtained after cleaning, manual cutting in half and pulping. use figure 2Shown flow process, each 100kg of passion fruit skin is packed into extraction tank 1,2,3,4 respectively, in each extraction tank, add the hot water of 800kg100 ℃, carry out solid-liquid separation after insulation extraction 3min, wherein, The peels in the extraction tanks 4, 3, and 2 were extracted 3 times, 2 times, and 1 time respectively, and the 4 jars of peels that had been extracted 3 times, 2 times, and 1 time respectively were obtained as the initial stage of countercurrent extraction. materials. Then start countercurrent extraction, inject 1000 kg of normal temperature production water A into the extraction tank 4 to cool for 2 minutes, and the liquid obtained through solid-liquid separation is heated to 80 ° C, that is, the extraction solution B, and the extraction solution B is poured into the extr...

Embodiment 3

[0035] After the leaching solution E is coarsely filtered by a duplex filter to remove impurities, ultrafiltration is performed with a 100KD ultrafiltration membrane to obtain an ultrafiltration permeate, and the ultrafiltration permeate is subjected to secondary reverse osmosis equipment under a pressure of 3MP. Reverse osmosis treatment, concentrating until the soluble solid content in the reverse osmosis retentate is higher than 20%, and collecting the reverse osmosis permeate and the reddish-brown reverse osmosis retentate respectively. The reverse osmosis permeate is reused as production water A, thereby reducing the consumption of water resources; while the reverse osmosis retentate enters the next production section.

[0036] The pericarp in the extraction tank 4 is cooled by the production water A, and the pericarp is discharged after solid-liquid separation. Now, the leaching work of the pericarp in the extraction tank 4 is all completed, and what is discharged is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com