Ultraviolet light curing adhesive composition and adhesive layer

A technology for adhesives and compositions, applied in the direction of adhesive types, non-polymer organic compound adhesives, polyurea/polyurethane adhesives, etc., can solve problems such as durability problems, and achieve excellent durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

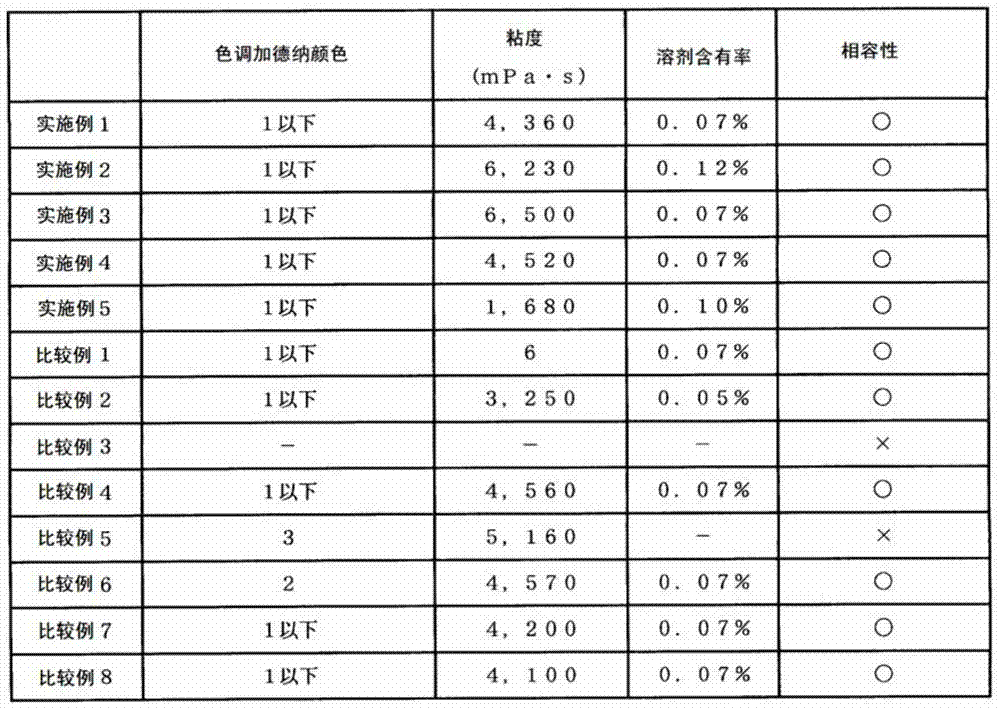

[0066] Hereinafter, the present invention will be explained more specifically through examples. However, the present invention is not limited to these examples. In addition, in the examples, unless otherwise specified, "parts" means "parts by weight".

[0067]

Synthetic example 1

[0069] (A-1) Synthesis of ingredients

[0070] Add 955 parts of polypropylene glycol with a weight average molecular weight of 4000, 34 parts of hexamethylene diisocyanate, and 0.2 parts of tin octoate to a reaction device equipped with a stirring device and a cooling pipe. The temperature is raised to 80°C, and the temperature is maintained for 2 hours, and then measured by NCO. It was confirmed that the reaction was completed and the urethane oligomer was formed, then 11 parts of 2-isocyanatoethyl methacrylate was added, and the mixture was kept at 80°C for 2 hours. The completion of the reaction was confirmed by NCO measurement, and a urethane methacrylate oligomer having a weight average molecular weight of 30000 and an average number of functional groups of 2.0 (hereinafter referred to as "(A-1) component") was obtained. In addition, the weight average molecular weight used a commercially available molecular weight analyzer (main product name "HLC-8220GPC", manufactured by T...

Synthetic example 2

[0072] (A-2) Synthesis of ingredients

[0073] In the same reaction device as Synthesis Example 1, 915 parts of polypropylene glycol with a weight average molecular weight of 4000, 68 parts of isophorone diisocyanate and 0.8 parts of tin octoate were added, the temperature was raised to 80°C, and the temperature was maintained for 2 hours, and acrylic acid-2- 17 parts of hydroxyethyl ester, kept at 80°C for 2 hours. The completion of the reaction was confirmed by NCO measurement, and a urethane acrylate oligomer having a weight average molecular weight of 25,000 and an average number of functional groups of 2.0 (hereinafter referred to as "(A-2) component") was obtained.

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com