High-current sensor calibration method based on curve fitting method

A calibration method and sensor technology, applied in the direction of instruments, measuring electrical variables, measuring devices, etc., can solve problems such as lack of calibration, affecting work efficiency, and damage to test benches, so as to achieve good applicability, ensure measurement accuracy, and high measurement and calibration The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

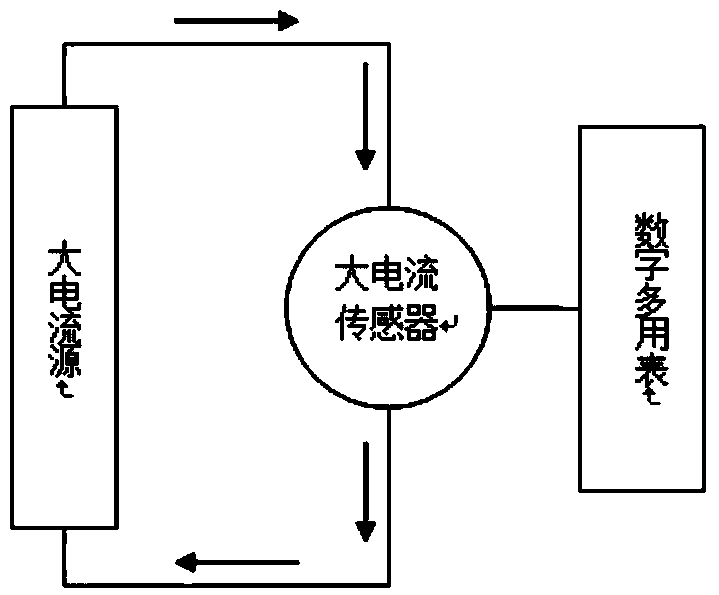

Method used

Image

Examples

Embodiment 1

[0055] Submitting Unit: Tianjin Tianchuan Electronic Control Equipment Testing Co., Ltd.

[0056] Device Name: High Current Sensor

[0057] Model specification: CWT150B

[0058] Factory number: 28479-25073

[0059] Production unit: PEM

[0060] Calibration date: June 26, 2014

[0061] Calibration location: Measuring room of Tianjin Tianchuan Electronic Control Equipment Testing Co., Ltd.

[0062] Output current range: 0-30KA, this example chooses to measure the full current value of 300A ~ 1000A as the calibration point

[0063] Output current accuracy: ±5%

[0064] Transformation ratio: 0.2mV / A

[0065] Ratio accuracy: ±1%

[0066] ⑴Appearance and accessories inspection

[0067] The shape and structure of the large current sensor should be intact. Switches, buttons, buttons, etc., are flexible and reliable in operation, with clear signs and no loose or mechanical damage to exposed parts. Its nameplate or shell should indicate its name, model, serial number, date of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com