Load cycle test insulating temperature gradient control method and system for high-voltage direct-current cables

A high-voltage direct current, temperature gradient technology, applied in the direction of testing the dielectric strength, etc., can solve the problem of accurate control of the outer surface temperature of the cable, and achieve the effect of meeting the research needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the following, the method for controlling the insulation temperature gradient of the high-voltage direct current cable load cycle test of the present invention will be described in detail with reference to specific implementation examples.

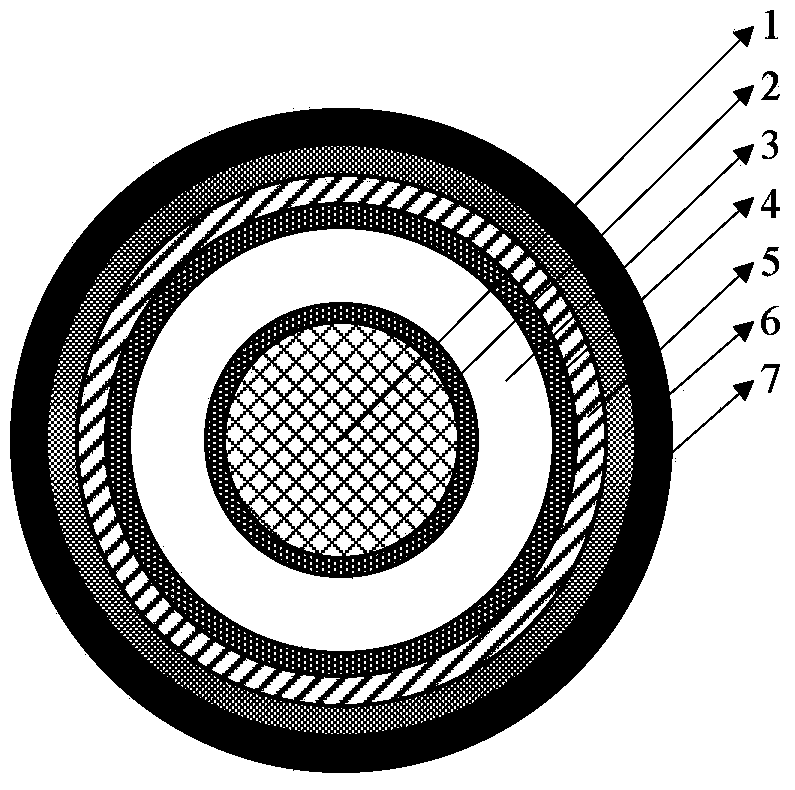

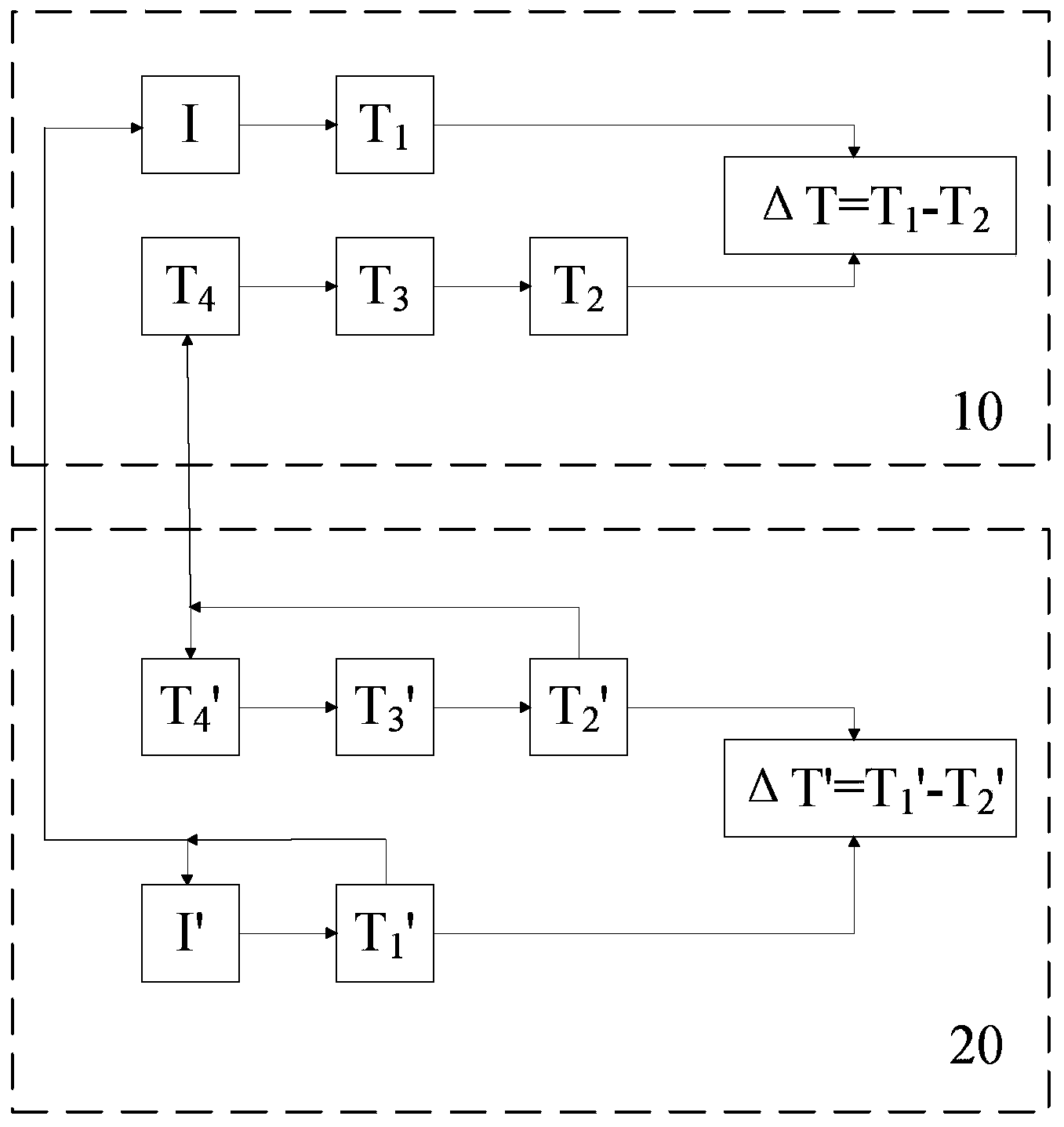

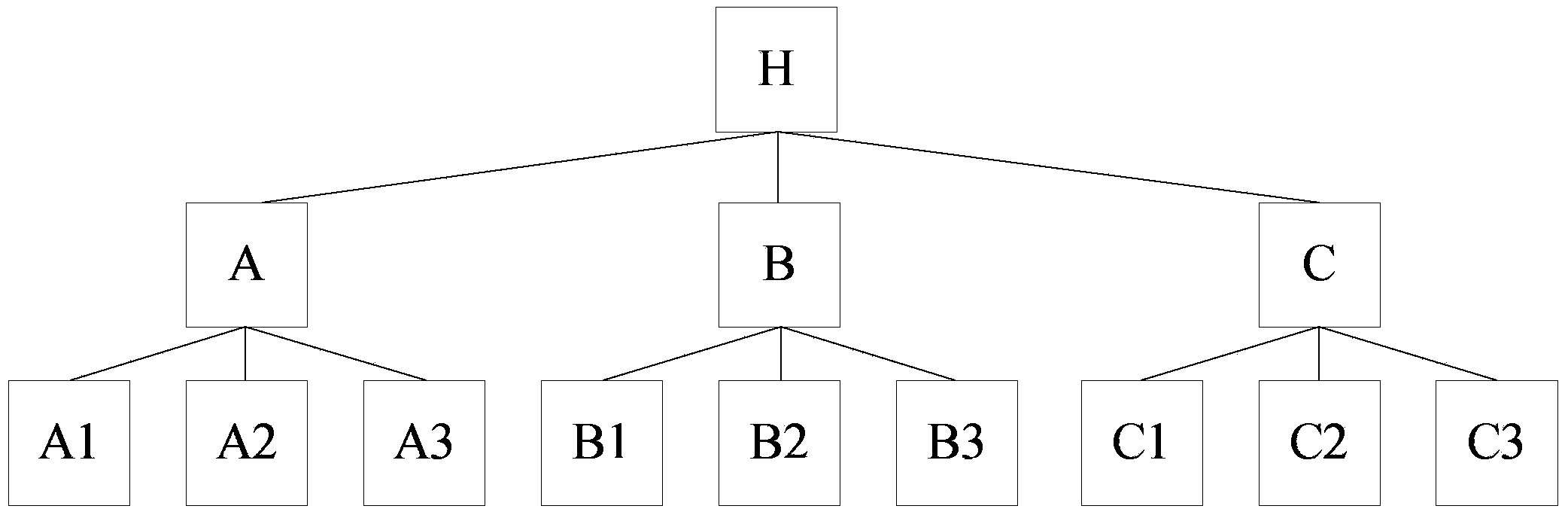

[0042] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the embodiment of the method for controlling the insulation temperature gradient of the high-voltage direct current cable load cycle test of the present invention includes the following steps:

[0043] S1, connect XLPE insulated high-voltage DC cables, joints and terminals into a spoon-shaped closed loop, called test loop 10;

[0044] The spoon shape is as follows: the cable is folded back from the middle to form two parallel sections, both ends of the cable are connected to the terminal and aligned horizontally, the folded part transitions through an arc whose radius is greater than the minimum bending radius of the cable, and one end of the folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com