Phenolic lampholder

A technology of bakelite and lamp holders, which is applied to lighting devices, components of lighting devices, lighting auxiliary devices, etc. It can solve problems such as unsafe hazards, large coordination deviations, environmental pollution, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

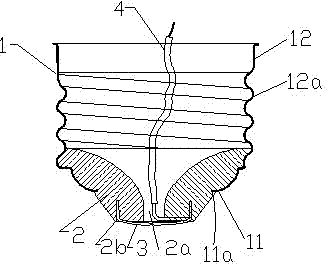

[0015] see figure 1 As shown, a bakelite lamp holder includes a metal casing 1, an insulator 2, a conductive cap 3 and a conductive wire 4, wherein: the metal casing 1 is integrally formed of a metal material, and its top 11 is provided with a through hole l1a, Threads 12a are provided on the outer wall 12 of the barrel body.

[0016] The insulator 2 is made of bakelite material and has an integrated structure. The bakelite is made of powdery resin, mixed with sawdust, asbestos or clay, and then pressed out of the finished product with a mold at high temperature; the formed insulator 2 is There is a wire inlet hole 2a through the insulator, and the insulator 2 is fixed in the through hole 11a of the metal casing 1 above.

[0017] The conductive cap 3 is installed on the top 2b of the insulator 2.

[0018] The conductive wire 4 is electricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com