High-power intelligent LED lamp rapid in heat dissipation

A technology of LED lights and LED lamps, applied in the direction of headlights, electric light circuit layout, energy-saving control technology, etc., can solve the problems of easy entry of ash and water, short lifespan, and inability to popularize the car lights, and achieve the effect of diversion and speeding up heat dissipation. , low cost, easy to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

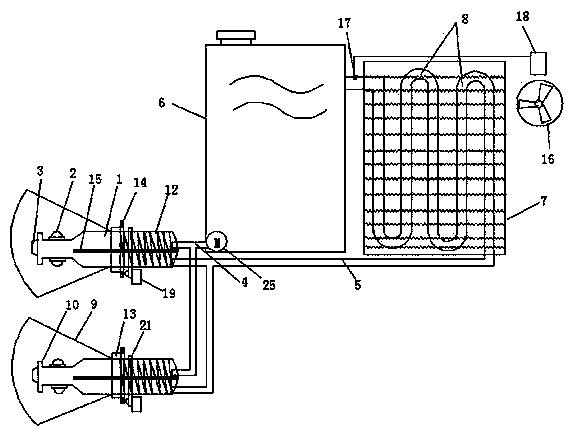

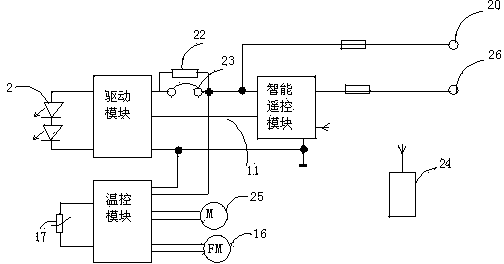

[0023] refer to figure 1 , this embodiment is proposed. This embodiment includes an LED lighting device and a liquid-cooled heat dissipation device; The front platform part has two installation planes up and down, and the upper and lower LED lamps are respectively installed on the two installation planes. The lamp body is a metal lamp body with good thermal conductivity; the liquid cooling device includes a water inlet pipe 4. Water outlet pipe 5, water pumping motor 25, liquid storage tank 6, radiator 7, the water inlet pipe 4 and water outlet pipe 5 are sealed and connected to the lamp body 1, the other end of the water inlet pipe is connected to the water pumping motor 25, and the water pumping motor 25 is located in the storage tank. The bottom of the liquid tank 6, the liquid storage tank 6 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com