Functional woven vamp cloth

A functional, shoe upper technology, applied in the field of woven fabrics, can solve the problems of inability to accurately control, time-consuming and yield, and achieve the effect of improving wear resistance and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Woven shoe upper fabric with wear resistance function

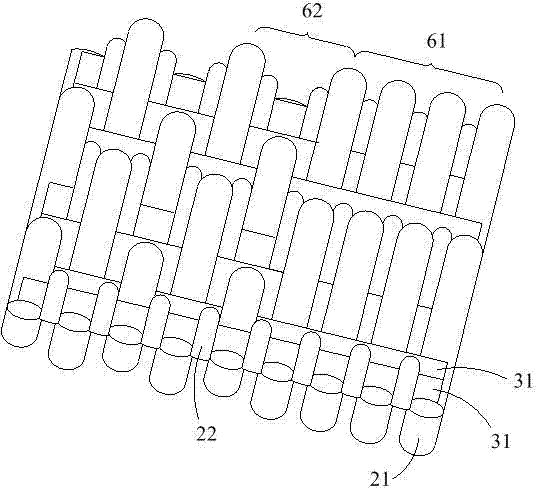

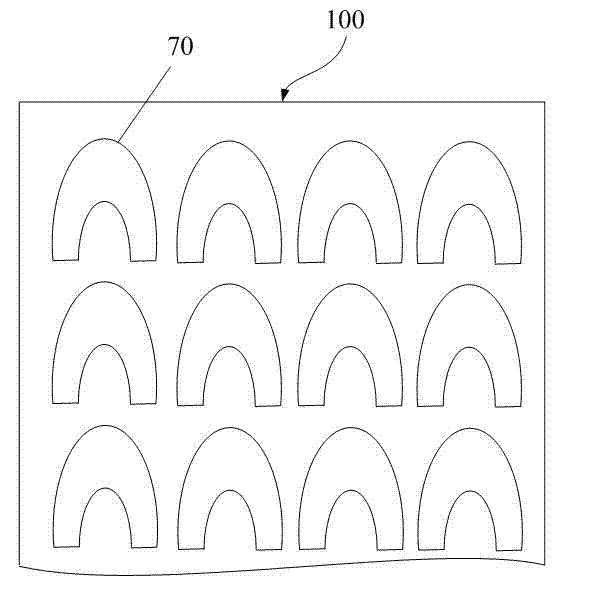

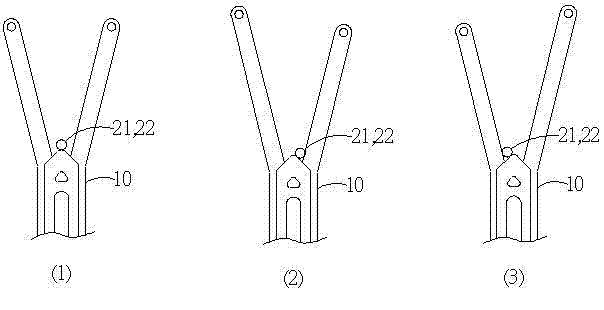

[0041] Please also refer to figure 1 and figure 2 , A plurality of first warp yarn units 21 and a second warp yarn unit 22 are arranged in parallel, and the diameter of the first warp yarn unit 21 is larger than that of the second warp yarn unit 22. According to the weaving plan of the weave pattern 70, the weft yarn unit 31 is passed through the plurality of Between the first warp yarn unit 21 and the plurality of second warp yarn units 22, the functional woven shoe upper fabric 100 is produced through the interlaced weaving method.

[0042] The present invention can also arrange the first warp yarn units 21 with a thicker diameter to form a wear-resistant protrusion 61, or match the second warp yarn units 22 with a thinner diameter according to the weaving plan of the organization pattern 70. The looser arrangement is to form a recess 62 with an aesthetic style. Through the matching of the weft units 31 of...

Embodiment 2

[0044] Example two, elastic and wear-resistant functional woven shoe upper fabric

[0045] When the yarn type is changed to elastic fiber yarn, in combination with the above technical solution, in addition to the above-mentioned wear resistance, the elastic yarn can also be used to provide appropriate elasticity, and the configuration can be configured through the planning of the organization pattern 70 And adjust the gap density between the warp units to avoid large deformation of the cloth pattern. In addition, the use of elastic fiber yarns can provide better coverage through its stretch and elasticity, and maintain the integrity of the upper pattern .

[0046] In practice, when the yarn type is elastic fiber yarn, the diameter of the first warp yarn unit 21 ranges from 300 deniers to 1200 deniers, and the diameter of the second warp yarn unit 22 ranges from 100 deniers to 450 deniers. The wire diameter of the unit 31 is between 100 deniers and 1200 deniers, and the wire diamet...

Embodiment 3

[0047] Embodiment three, woven shoe upper fabric with see-through and wear-resistant function

[0048] When the yarn type is monofilament fiber yarn, using the strength of monofilament fiber yarn can improve the shortcomings of insufficient strength of traditional composite spinning. Due to the stiffness of monofilament fiber yarn, the pore planning ratio of the structure pattern 70 can be increased. , The implementation of the upper hole planning ratio can reach 20% to 70%. When the hole planning ratio is too small, the yarns will shield each other and make the perspective poor. When the hole planning ratio is too large, the overall shoe upper fabric strength will not match Required, the more commonly used application ratio is 30% to 60%. In addition, the color rendering of monofilament fibers is more fuller than composite spinning, which not only highlights the perspective of the upper fabric, but also increases the hazy beauty.

[0049] In practice, when the yarn type is monofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com